Skid Mounted Thermal Oil Boiler | Compact & Energy-Efficient Heating

The industrial heating landscape is undergoing significant transformation, with Skid mounted thermal oil boiler systems emerging as a cornerstone technology for efficient and flexible thermal energy delivery. As global industries seek more modular, space-efficient heating solutions, these advanced boiler systems are revolutionizing process heating across multiple sectors.

About Hebei Yineng Boiler Co., Ltd.

As a leading innovator in boiler technology, Hebei Yineng Boiler Co., Ltd. specializes in advanced thermal solutions designed for modern industrial requirements. With extensive experience in thermal engineering, we provide state-of-the-art boiler systems that combine efficiency, reliability, and innovative design.

Corporate Profile

Since our establishment, we've focused on developing innovative heating solutions that address the evolving needs of industries worldwide. Our Skid mounted thermal oil boiler systems represent our commitment to engineering excellence and customer-focused solutions.

Contact Information

Address: Wuqiao, Hebei, China

Phone: +8613833185003

Email: leesonzhou@aliyun.com

Visit Our WebsiteProduct Spotlight: Skid Mounted Thermal Oil Boiler

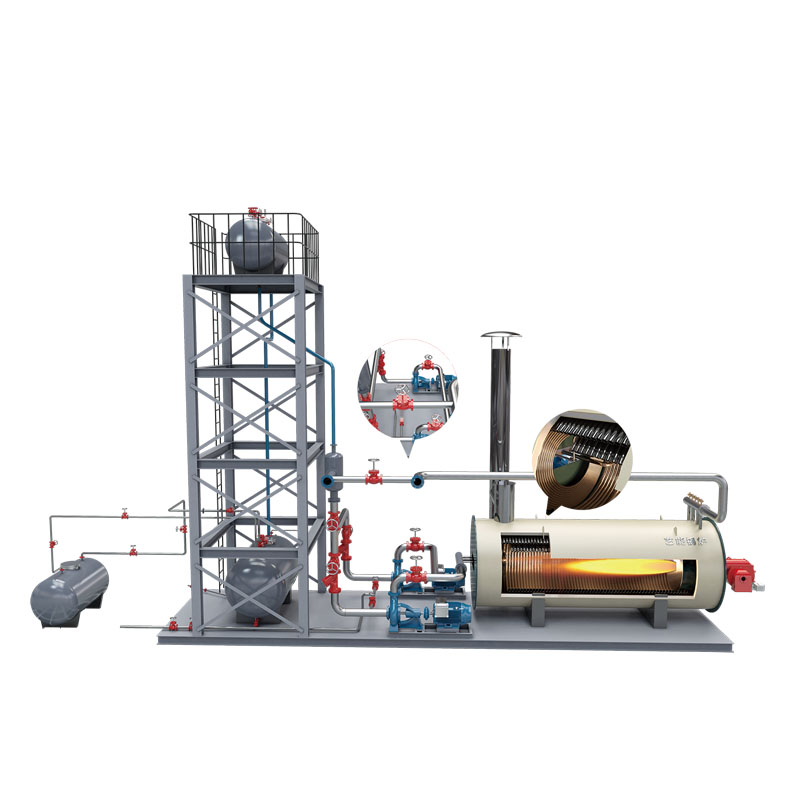

Packaged boilers (skid-mounted boilers), also known as quick-installed boilers, are boilers provided by our company that are convenient for users to install on site. Our Skid mounted thermal oil boiler systems are engineered for rapid deployment and optimal thermal efficiency.

These systems represent the cutting edge in thermal engineering, combining compact design with high-capacity thermal transfer capabilities. Pre-assembled and factory-tested, our boilers significantly reduce installation time and site preparation costs while maintaining the highest industry standards for performance and safety.

Learn More About Our Boiler SystemsIndustry Trends and Applications

Emerging Market Trends

The thermal fluid heater market is projected to grow at 6.2% CAGR from 2023 to 2030, with Skid mounted thermal oil boiler systems representing the fastest-growing segment according to Global Market Insights. This growth is fueled by increasing demand from chemical processing, food production, and manufacturing industries seeking modular, efficient heating solutions.

Key industry developments include the integration of IoT monitoring systems, advanced combustion control algorithms, and the development of high-performance thermal fluids capable of operating at up to 400°C with minimal degradation. Modern Skid mounted thermal oil boiler units now incorporate predictive maintenance capabilities that can reduce downtime by up to 40%.

Application Scenarios

Skid mounted thermal oil boiler systems excel in numerous industrial applications:

- Chemical Processing: Provides precise temperature control for reactors, distillation columns, and polymer production

- Food Manufacturing: Offers contamination-free heating for processes like frying, baking, and dehydration

- Manufacturing: Powers presses, vulcanization equipment, and coating/drying processes

- Renewable Energy: Supports biofuel production and waste-to-energy systems

- Pharmaceutical: Ensures compliant heating for sterilization and synthesis processes

The portability and rapid commissioning of Skid mounted thermal oil boiler systems make them ideal for temporary facilities, remote operations, and rapidly expanding production facilities.

Technical Specifications and Performance Data

Standard Specifications

| Parameter | Model YNS-250 | Model YNS-500 | Model YNS-1000 | Model YNS-2000 |

|---|---|---|---|---|

| Thermal Capacity (kW) | 250 | 500 | 1000 | 2000 |

| Working Pressure (MPa) | 0.8 | 1.0 | 1.0 | 1.2 |

| Design Temperature (°C) | 320 | 340 | 350 | 370 |

| Heat Transfer Fluid | Synthetic/ Mineral Thermal Oil | |||

| Thermal Efficiency (%) | 85-88 | 86-89 | 87-91 | 88-92 |

| Fuel Options | Natural Gas, Diesel, Heavy Oil, Biomass, Dual-fuel | |||

| NOx Emissions (mg/m³) | < 90 | < 85 | < 80 | < 75 |

| Footprint (LxWxH meters) | 2.5x1.8x2.2 | 3.2x2.0x2.5 | 4.0x2.5x3.0 | 5.5x3.0x3.5 |

Performance Comparison

Temperature Capabilities

Market Adoption Growth

Key Technical Advantages of Our Systems

Enhanced Design Features

Our Skid mounted thermal oil boiler systems incorporate numerous patented features that enhance performance:

- Triple-Pass Coil Design: Maximizes heat transfer efficiency while minimizing thermal stress

- Advanced Insulation: Ceramic fiber insulation reduces exterior temperatures and heat loss by up to 30%

- Modular Control System: PLC-based control with remote monitoring and predictive diagnostics

- High-Temperature Pumps: Sealless magnetic drive pumps rated for continuous operation at 400°C

- Dual-Safety Systems: Redundant pressure and temperature controls with automatic shutdown protocols

Operational Benefits

Modern Skid mounted thermal oil boiler installations provide significant operational advantages:

- 75% reduction in installation time compared to conventional boilers

- 30-40% space savings through compact design

- 10-15% lower fuel consumption through optimized combustion systems

- Compliance with international standards including ASME, PED, and IBR

- Simplified maintenance through accessible component arrangement

- Compatibility with various fuel sources including renewables

The comprehensive engineering behind our Skid mounted thermal oil boiler systems delivers reliable, continuous operation even in challenging industrial environments.

Professional FAQ: Technical Aspects Explained

Our Skid mounted thermal oil boiler systems utilize carbon steel (ASTM A106 Gr. B) for primary circuits and stainless steel (SS304/SS316) for critical high-temperature components. The coil systems employ seamless steel tubing meeting ASME SA-178/SA-192 specifications with a minimum pressure rating of 3 MPa. For applications requiring temperatures above 350°C, we employ specialized alloy steels with enhanced creep resistance.

Thermal oil boilers must comply with multiple international standards, including ASME Section I for power boilers, PED 2014/68/EU for European markets, and ISO 13705 for petroleum industries. Critical safety systems include redundant high-limit temperature controls (EN 12953), pressure relief valves (ASME Section VIII), low-flow protection, and comprehensive flame monitoring systems. Our Skid mounted thermal oil boiler systems incorporate SIL-2 rated safety controllers meeting IEC 61508 standards.

Skid mounted thermal oil boiler systems typically achieve 87-92% thermal efficiency, significantly higher than steam systems at similar temperature ranges. This efficiency advantage comes from eliminating phase change energy losses, reduced heat transfer resistance, and minimized blowdown requirements. Advanced thermal oil boilers can maintain efficiencies above 90% across 30-100% load ranges through modulated burner control and optimized coil designs.

Typical requirements include a level concrete foundation with 150mm thickness, adequate ventilation per NFPA 86 standards (minimum 0.03m³/s per kW), electrical supply per local codes, and sufficient clearance for maintenance access (minimum 1m on all sides). Our Skid mounted thermal oil boiler systems significantly simplify installation with all major components pre-assembled, pre-wired, and hydrostatically tested. Connection points are standardized for rapid integration with existing systems.

Recommended maintenance includes quarterly combustion analysis and adjustment, semi-annual thermal fluid testing (measuring viscosity, TAN, flash point), annual burner servicing, and inspection of refractory materials. Coil systems require inspection every 8,000 hours for carbon buildup and erosion. Our systems feature integrated monitoring that tracks performance metrics and alerts for predictive maintenance, reducing unplanned downtime by up to 60%.

Advanced Skid mounted thermal oil boiler systems employ multiple emission control technologies including FGR (Flue Gas Recirculation) systems to reduce thermal NOx formation, multi-stage combustion technology that lowers flame temperatures, and selective catalytic reduction (SCR) for applications requiring ultra-low emissions. Our standard systems achieve NOx levels below 80 mg/m³ without additional treatment, meeting most international environmental standards.

Standard Skid mounted thermal oil boiler systems operate effectively between 150°C and 350°C, with specialized high-temperature units capable of reaching 400°C using synthetic thermal fluids. Temperature stability is typically maintained within ±1°C through advanced PID control systems. The maximum temperature is limited by thermal fluid properties, with synthetic fluids providing superior high-temperature stability compared to mineral-based oils.

Industry References and Technical Resources

-

Skid Mounted Thermal Oil Boiler | Compact & Energy-Efficient HeatingNewsJul.20,2025

-

Industrial Steam Boiler Corporation - Reliable Industrial Boiler Manufacturer & SupplierNewsJul.08,2025

-

High-Efficiency Steam Boiler Heat Exchanger Supplier & Factory Durable Products for IndustryNewsJul.08,2025

-

Premium Electric Steam Boiler Manufacturer Reliable Company & Factory SolutionsNewsJul.08,2025

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025