waste heat recovery boiler manufacturers manufacturer

Waste Heat Recovery Boiler Manufacturers Pioneering Energy Efficiency

In an era where sustainability and energy efficiency are paramount, waste heat recovery boilers have emerged as crucial players in optimizing industrial energy consumption. Waste heat recovery systems capture the excess heat generated from various processes and convert it into usable energy, significantly reducing the overall energy cost and minimizing environmental impact. This article explores the role of waste heat recovery boiler manufacturers in driving this innovative technology and highlights their contributions to industrial efficiency.

Understanding Waste Heat Recovery Boilers

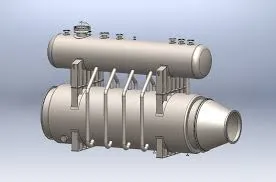

Waste heat recovery boilers are specialized devices designed to convert wasted thermal energy into useful thermal or electrical energy. Industries such as oil and gas, cement, steel, and power generation often produce substantial amounts of waste heat. By employing waste heat recovery systems, organizations can harness this energy, thereby improving their operational efficiency and contributing positively to their bottom line.

The design of these boilers varies based on the specific needs of industry applications. Generally, they utilize the exhaust gas from combustion processes, steam from production, or hot air from operations. The recovered energy can be used for preheating, generating steam, or even producing electricity, all of which help offset energy costs.

The Role of Manufacturers

Manufacturers of waste heat recovery boilers play a vital role in advancing the adoption of this technology. They are responsible for designing, engineering, and fabricating systems that can efficiently capture and convert waste heat. Key players in this industry focus on several aspects

1. Innovation and Engineering Advanced manufacturing technologies are pivotal in developing new types of waste heat recovery boilers. Manufacturers invest in research and development to enhance system efficiency, durability, and scalability. Innovations such as multi-pressure systems, enhanced heat exchangers, and smart monitoring systems significantly improve the performance of these boilers.

waste heat recovery boiler manufacturers manufacturer

2. Customization Each industrial application presents unique challenges. Leading manufacturers offer tailored solutions that cater to specific operational requirements. They work closely with clients to understand their processes and design waste heat recovery systems that maximize energy recovery while minimizing costs.

3. Sustainability Focus In line with global sustainability goals, manufacturers are increasingly emphasizing eco-friendly practices. This includes utilizing sustainable materials in boiler construction, reducing emissions, and ensuring that systems comply with environmental regulations. Their commitment to sustainability not only benefits the environment but also enhances the reputation of the companies that adopt these technologies.

4. After-sales Support and Maintenance Beyond manufacturing, reputable companies provide essential after-sales service, including installation, maintenance, and performance monitoring. This support is critical for ensuring optimal functionality and longevity of waste heat recovery systems.

Industry Impact

The impact of waste heat recovery boiler manufacturers extends far beyond individual industries. By facilitating the recovery of waste heat, these systems help reduce greenhouse gas emissions and lower the carbon footprint of industrial operations. As industries worldwide strive to meet stricter emissions standards, the integration of waste heat recovery technology becomes increasingly vital.

Moreover, the economic benefits are substantial. By reducing energy consumption, organizations can achieve significant cost savings, improve energy security, and enhance competitiveness in their respective markets. The continuous evolution of this technology is leading to improved energy efficiencies, benefiting both manufacturers and end-users alike.

Conclusion

Waste heat recovery boiler manufacturers are at the forefront of a crucial transformation in energy management. By offering innovative, customized solutions, they not only enhance industrial efficiency but also contribute significantly to global sustainability efforts. As the demand for energy-efficient technologies continues to rise, these manufacturers will play an essential role in shaping the future of energy recovery and consumption. Industries that embrace waste heat recovery will not only improve their bottom lines but also position themselves as leaders in sustainability and environmental responsibility.

-

Top Electric Steam Boiler Manufacturers | Industrial Steam SolutionsNewsJul.26,2025

-

Top Electric Steam Boiler Manufacturers – Reliable Industrial SolutionsNewsJul.25,2025

-

Top Electric Steam Boiler Manufacturers – Reliable Industrial SolutionsNewsJul.24,2025

-

Top Electric Steam Boiler Manufacturers – High Efficiency & ReliabilityNewsJul.23,2025

-

Best China Steam Boiler Price for Efficient Industrial HeatingNewsJul.22,2025

-

Top Electric Steam Boiler Manufacturers - High-EfficiencyNewsJul.21,2025