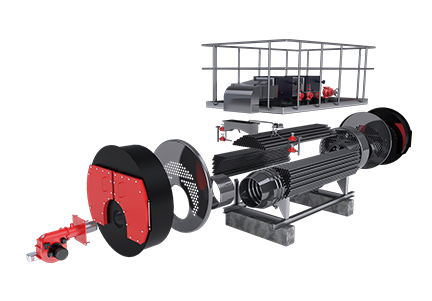

industrial thermal oil heater product

Industrial Thermal Oil Heater A Comprehensive Overview

In the realm of industrial heating solutions, thermal oil heaters emerge as a pivotal technology, offering efficient and reliable heating for various industrial processes. These systems have found extensive applications in sectors such as petrochemicals, food processing, pharmaceuticals, and more, where precise temperature control and consistent thermal performance are crucial.

How Thermal Oil Heaters Work

Thermal oil heaters operate on the principle of heat transfer using a specialized fluid—typically thermal oil or heat transfer fluid—that circulates through the system to absorb and carry heat to the required areas. The basic components of a thermal oil heater include a furnace, heat exchanger, circulation pump, expansion tank, and safety equipment.

1. Furnace The process begins in the furnace, where fuel (natural gas, oil, or biomass) is combusted to generate heat. The furnace is designed to ensure optimal fuel efficiency and maximized heat transfer.

2. Heat Transfer Fluid The heat generated in the furnace is transferred to the thermal oil circulating through the system. Unlike traditional steam heating systems, thermal oil can be heated to much higher temperatures (up to 300°C or more) without the associated pressure risks of saturated steam.

3. Circulation System The heated thermal oil is circulated through an insulated piping system to various heat exchangers that distribute heat across different processes or equipment, maintaining continuous operation.

4. Expansion Tank As thermal oil is heated, it expands. An expansion tank accommodates this expansion, ensuring that the system operates within safe parameters and preventing excess pressure buildup.

5. Safety Features Modern thermal oil heaters are equipped with advanced safety features, including temperature and pressure sensors, automatic shut-off valves, and more, designed to prevent overheating and other potential hazards.

Benefits of Thermal Oil Heaters

1. High Efficiency Thermal oil heaters are designed to achieve high thermal efficiency, often exceeding 90%. This efficiency translates to reduced fuel consumption and lower operational costs, making them an economically viable choice for industrial applications.

industrial thermal oil heater product

2. Versatility Thermal oil systems are versatile and can be tailored to meet the specific heating requirements of various industrial processes, whether it involves heating fluids, drying materials, or maintaining specific temperature profiles for chemical reactions.

3. Stable Temperature Control The ability to maintain consistent temperatures is vital in many industrial processes. Thermal oil heaters provide precise temperature control, which minimizes temperature fluctuations that can adversely affect product quality.

4. Safety and Environmental Benefits The risk of explosions and pressure-related incidents associated with steam heating is minimized with thermal oil heaters. Additionally, they can be designed to operate on renewable energy sources, thus reducing the carbon footprint of industrial operations.

Applications of Thermal Oil Heaters

Thermal oil heaters are deployed across numerous industries, including

- Petrochemical Industry Used for heating crude oil, distillation units, and process heating in refineries. - Food Industry Frequently applied in processes such as frying, baking, and drying, where consistent and controlled temperatures are critical. - Chemical Manufacturing Essential for various reactions and processes that require precise thermal management. - Manufacturing Utilized for curing, molding, and shaping thermosetting materials and coatings.

Choosing the Right Thermal Oil Heater

Selecting an appropriate thermal oil heater involves assessing several factors, including the specific heating requirements, available fuel types, operational costs, and safety standards. It is crucial to consult with manufacturers or industry experts to design a tailored system that meets the unique demands of your facility.

Conclusion

In conclusion, industrial thermal oil heaters represent a cornerstone of efficient heating technology across numerous sectors. Their ability to provide high-efficiency heat transfer, precise temperature control, and enhanced safety features makes them an ideal solution for various industrial applications. As industries continue to seek sustainable and cost-effective heating solutions, the relevance and adoption of thermal oil heaters are likely to grow, marking them as a key component of the future of industrial heating.

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025