OEM Thermal Oil Boiler Solutions for Efficient EPS Production Processes

The Advantages and Applications of OEM Thermal Oil Boilers for EPS Manufacturing

In the modern industrial landscape, efficiency and precision are key to maintaining competitiveness and profitability. One area where this is particularly evident is in the production of Expanded Polystyrene (EPS) foam, widely used in packaging, insulation, and construction materials. An essential component in the manufacturing process of EPS is the thermal oil boiler, especially those manufactured by Original Equipment Manufacturers (OEMs). This article explores the benefits of OEM thermal oil boilers for EPS production and their applications in the industry.

Understanding Thermal Oil Boilers

Thermal oil boilers are specialized heating systems that use oil as a heat transfer medium instead of water or steam. This design allows for the maintenance of high temperatures at lower pressures, making them suitable for various industrial processes, including the production of EPS. The use of thermal oil provides a stable and efficient way of transferring heat to processes that require consistent and high thermal energy.

The Role of OEMs in Thermal Oil Boiler Production

Original Equipment Manufacturers (OEMs) play a vital role in the production of thermal oil boilers tailored to meet specific industrial needs. These manufacturers focus on engineering high-quality boilers that comply with stringent safety and efficiency standards. By leveraging advanced technologies and materials, OEM thermal oil boilers ensure reliability, longevity, and superior performance in demanding applications like EPS manufacturing.

Advantages of OEM Thermal Oil Boilers for EPS

1. High Efficiency OEM thermal oil boilers are designed to operate with high thermal efficiency, minimizing energy consumption while maximizing output. This efficiency is crucial in EPS production, helping manufacturers reduce operational costs and their carbon footprint.

2. Temperature Control The ability to maintain precise temperature control is essential in the EPS manufacturing process. Thermal oil boilers can achieve and sustain high temperatures (up to 300°C or more) without the risk of overheating or pressure build-up, ensuring optimal material properties and consistency in production.

3. Safety Features Safety is a top priority in any industrial operation. OEM thermal oil boilers come equipped with numerous safety features, such as pressure relief valves, temperature monitoring systems, and automatic shut-off mechanisms. This ensures safe operation, protecting both personnel and equipment.

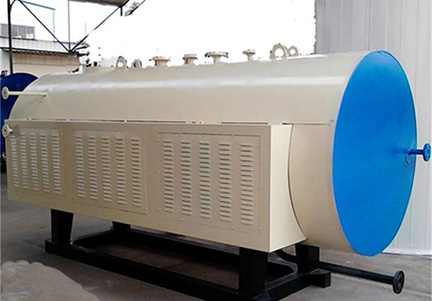

oem thermal oil boiler for eps

4. Flexibility and Versatility These boilers can be used in various applications beyond EPS production, making them versatile assets in the manufacturing sector. They are suitable for applications like plastic processing, food industry heating, and chemical processing.

5. Customizability OEMs often provide customized solutions to meet the unique needs of different manufacturers. This means that the thermal oil boiler can be tailored in terms of capacity, design, and features to align perfectly with specific production processes.

Applications of Thermal Oil Boilers in EPS Manufacturing

Thermal oil boilers are central to the EPS manufacturing process, wherein they serve multiple applications

- Pre-expansion Thermal oil boilers supply the necessary heat for the pre-expansion of polystyrene beads, a critical step in producing EPS. Controlled heating ensures uniform expansion and optimal bead quality.

- Molding In the molding stage, thermal oil is used to maintain the temperature of molds, ensuring precise shaping and consistency in EPS products.

- Drying Post-production, thermal oil can be utilized to provide the necessary heat for drying EPS products, enhancing their durability and readiness for use.

- Recycling As the industry leans towards sustainability, thermal oil boilers are also employed in recycling processes, where they assist in breaking down EPS waste material for reuse.

Conclusion

The integration of OEM thermal oil boilers in EPS manufacturing marks a significant advancement in the industry's efficiency and quality production standards. With their high operational efficiency, precise temperature control, safety features, and versatility, these boilers are valuable assets. As the demand for EPS continues to rise, investing in high-quality OEM thermal oil boilers will undoubtedly lead to enhanced productivity, reduced costs, and improved product quality in the fast-evolving industrial landscape.

-

High-Efficiency OEM Steam Boilers w/GPT-4-TurboNewsAug.02,2025

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025