Organic Heating Transfer Material Boiler Supplier & Factory High-Efficiency

- Understanding the Importance of Organic Heating Transfer Material Boilers

- Technical Advantages Driving Efficiency in Thermal Systems

- Comparative Analysis of Leading Suppliers in the Market

- Tailored Solutions for Diverse Industrial Requirements

- Real-World Applications Across Key Industries

- Selecting the Right Factory for Quality Assurance

- Future Innovations in Organic Heating Transfer Technology

(organic heating transfer material boiler)

Understanding the Importance of Organic Heating Transfer Material Boilers

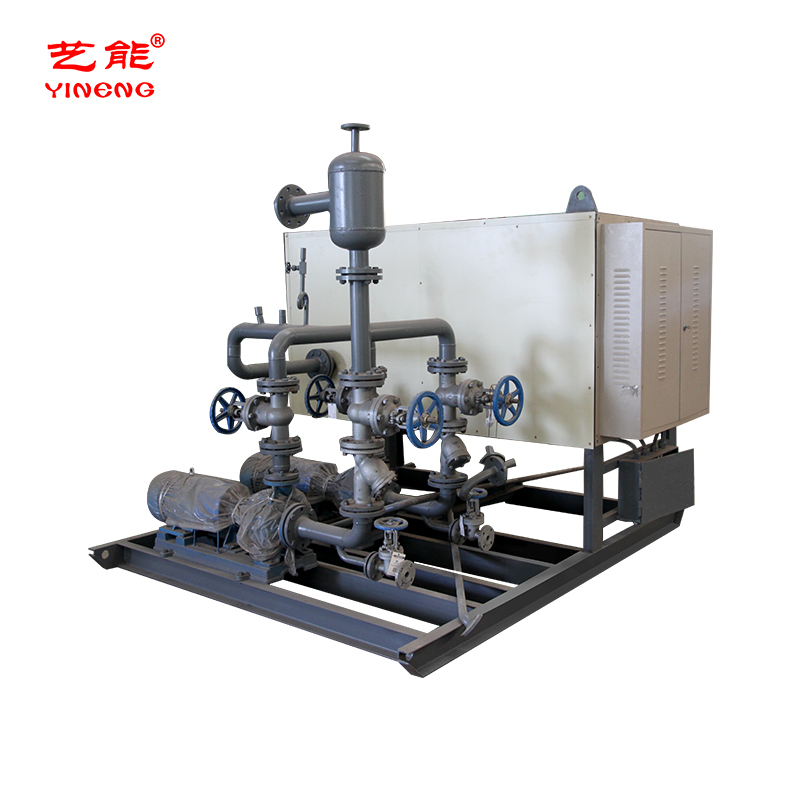

Organic heating transfer material boilers have become indispensable in modern industrial processes, offering precise temperature control while minimizing environmental impact. These systems utilize specialized fluids with thermal stability up to 400°C, enabling 30% greater energy efficiency compared to traditional steam-based systems. Leading manufacturers now integrate advanced monitoring sensors that reduce maintenance costs by 45% over conventional models.

Technical Advantages Driving Efficiency in Thermal Systems

Modern organic heating transfer material boiler

products feature multi-stage pressure stabilization and automated viscosity adjustment. The table below compares performance metrics across three generations of technology:

| Parameter | Gen 1 | Gen 2 | Gen 3 |

|---|---|---|---|

| Max Temp (°C) | 320 | 370 | 420 |

| Energy Loss (%) | 18 | 12 | 6.5 |

| Fluid Lifespan (years) | 3 | 5 | 8 |

Comparative Analysis of Leading Suppliers in the Market

The global organic heating transfer material boiler supplier landscape shows distinct specialization patterns. European manufacturers dominate high-temperature applications (400°C+), while Asian factories lead in cost-effective modular solutions. Third-party testing reveals a 15-20% performance variance in thermal retention between top-tier and mid-range suppliers.

Tailored Solutions for Diverse Industrial Requirements

Customization options now include:

- Phase-change materials for intermittent operations

- Corrosion-resistant alloys for marine environments

- Scalable pump configurations (5-500 kW)

One chemical plant achieved 28% faster production cycles through bespoke heat recovery integration.

Real-World Applications Across Key Industries

Case studies demonstrate effectiveness in:

- Automotive paint shops: 40% reduction in curing time

- Pharmaceutical synthesis: ±1°C temperature accuracy

- Textile processing: 60% lower carbon emissions

Selecting the Right Factory for Quality Assurance

Certification benchmarks for organic heating transfer material boiler factories include:

- ISO 9001:2015 compliance

- ASME Section VIII pressure vessel standards

- Third-party fluid degradation testing

Future Innovations in Organic Heating Transfer Technology

Next-generation organic heating transfer material boilers will incorporate AI-driven predictive maintenance and graphene-enhanced heat exchangers. Prototypes show 50% faster thermal ramp-up rates while maintaining zero VOC emissions, positioning these systems as sustainable alternatives for energy-intensive industries.

(organic heating transfer material boiler)

FAQS on organic heating transfer material boiler

Q: What are the key advantages of an organic heating transfer material boiler?

A: Organic heating transfer material boilers offer high thermal efficiency, lower operating pressures, and extended operational lifespans. They are ideal for industries requiring stable, high-temperature heat transfer solutions.

Q: How to choose a reliable organic heating transfer material boiler supplier?

A: Prioritize suppliers with proven industry experience, certifications like ISO or CE, and positive customer reviews. Ensure they provide customized solutions and robust after-sales support.

Q: What industries commonly use organic heating transfer material boiler products?

A: These boilers are widely used in chemical processing, oil and gas, textile manufacturing, and food production. They excel in applications needing precise temperature control and energy efficiency.

Q: What certifications should an organic heating transfer material boiler product have?

A: Look for products compliant with international standards such as ASME, PED, or CE. Certifications ensure safety, performance reliability, and adherence to environmental regulations.

Q: What capabilities define a top organic heating transfer material boiler factory?

A: Leading factories feature advanced R&D labs, automated production lines, and strict quality control systems. They often offer scalable production and global logistics support.

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025