Efficient Gas-Fired Steam Boiler Solutions for Industrial Applications and Energy Savings

Gas-Fired Steam Boiler An Overview

Gas-fired steam boilers play a crucial role in various industrial processes and applications. They are widely utilized for heating, power generation, and providing steam for manufacturing processes. Their efficiency and reliability make them a preferred choice in numerous sectors, from manufacturing to healthcare facilities. This article explores the fundamental aspects of gas-fired steam boilers, including their operation, benefits, maintenance, and environmental considerations.

Operation of Gas-Fired Steam Boilers

At the core of a gas-fired steam boiler is the combustion of natural gas or liquefied petroleum gas (LPG). The boiler consists of a combustion chamber where gas is ignited, producing hot gases. These gases then pass through a heat exchanger, transferring their heat to water, which is converted into steam. The steam is then either used directly for heating purposes or routed to turbines for electricity generation.

The efficiency of gas-fired steam boilers is significantly influenced by their design and technology. Modern systems often feature advanced controls and monitoring equipment, which enhance operational performance and reduce fuel consumption. High-efficiency boilers can achieve an efficiency rating of up to 90%, resulting in lower fuel expenses and reduced greenhouse gas emissions.

Benefits of Gas-Fired Steam Boilers

One of the primary advantages of gas-fired steam boilers is their fuel efficiency. Natural gas is typically less expensive than other fossil fuels, such as oil or coal, making it a cost-effective option for industries reliant on steam. Additionally, natural gas burns cleaner than other fuels, producing lower amounts of particulate matter, sulfur dioxide, and nitrogen oxides, which contributes to improved air quality.

Gas-fired steam boilers are also known for their quick start-up times and operational flexibility. They can ramp up or down quickly in response to fluctuating demand, which is particularly beneficial in facilities with varying steam requirements. Furthermore, they require less maintenance compared to coal-fired or oil-fired boilers, translating to reduced downtime and lower maintenance costs.

Applications of Gas-Fired Steam Boilers

Gas-fired steam boilers are versatile and can be found in a wide range of applications. In manufacturing processes, steam is essential for tasks such as sterilization, mixing, and heating. The food and beverage industry heavily relies on steam for cooking, pasteurization, and cleaning processes.

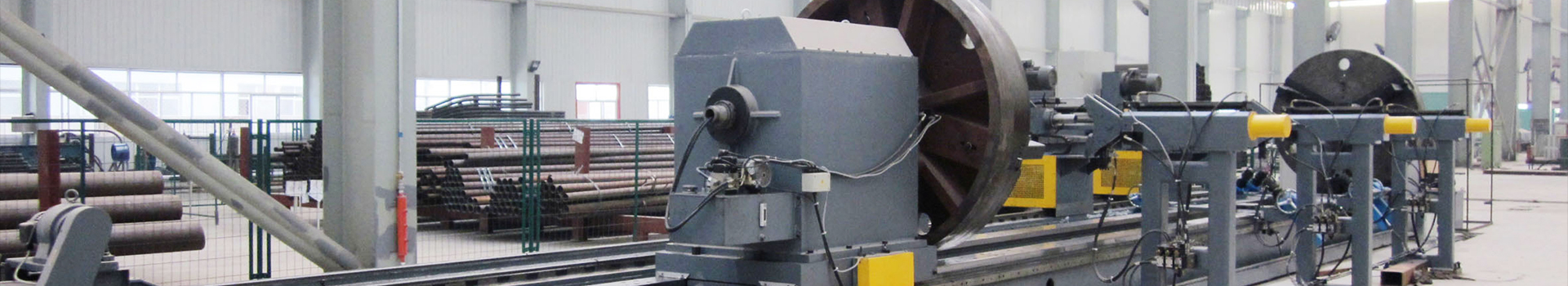

gas fired steam boiler

In the energy sector, gas-fired steam boilers are integral to power plants, where they are used to generate electricity. They are also used in district heating systems, where steam is distributed through pipelines to provide heat to residential and commercial buildings.

Healthcare facilities utilize gas-fired steam boilers in their sterilization processes, ensuring that equipment and instruments are sanitized effectively. Residential heating systems also leverage gas-fired boilers, maintaining comfortable living environments during cold seasons.

Maintenance Considerations

Regular maintenance of gas-fired steam boilers is crucial to ensure their efficiency and longevity. Routine inspection of burner systems, heat exchangers, and pressure controls helps in identifying potential issues before they escalate. Regular cleaning of the combustion chamber and flue gas paths prevents soot buildup, which can hinder heat transfer and reduce efficiency.

Water quality is another critical factor in boiler maintenance. The presence of impurities can lead to scaling and corrosion, affecting system performance. Implementing water treatment protocols can mitigate these risks, ensuring that the boiler operates at optimal efficiency.

Environmental Considerations

As industries strive for sustainability, gas-fired steam boilers present a greener alternative to traditional fossil fuel systems. The lower emissions associated with natural gas make it an attractive option for companies aiming to reduce their carbon footprint. Additionally, the trend towards integrating renewable energy sources, such as biogas, into combustion processes further enhances the environmental benefits of gas-fired steam boilers.

Conclusion

In summary, gas-fired steam boilers are a vital component in a wide range of industries, offering benefits such as efficiency, flexibility, and lower emissions compared to other fossil fuel systems. Their ability to provide reliable steam for various applications, combined with relatively lower maintenance needs, makes them a preferred choice in the industrial landscape. As technology advances and regulations become more stringent, gas-fired steam boilers are likely to continue evolving, paving the way for a more sustainable future in steam generation.

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025