Leading Manufacturer of Reliable Fixed-Percentage Thermal Oil Boilers for Industrial Applications

Understanding Fixed Grate Thermal Oil Boilers A Comprehensive Overview

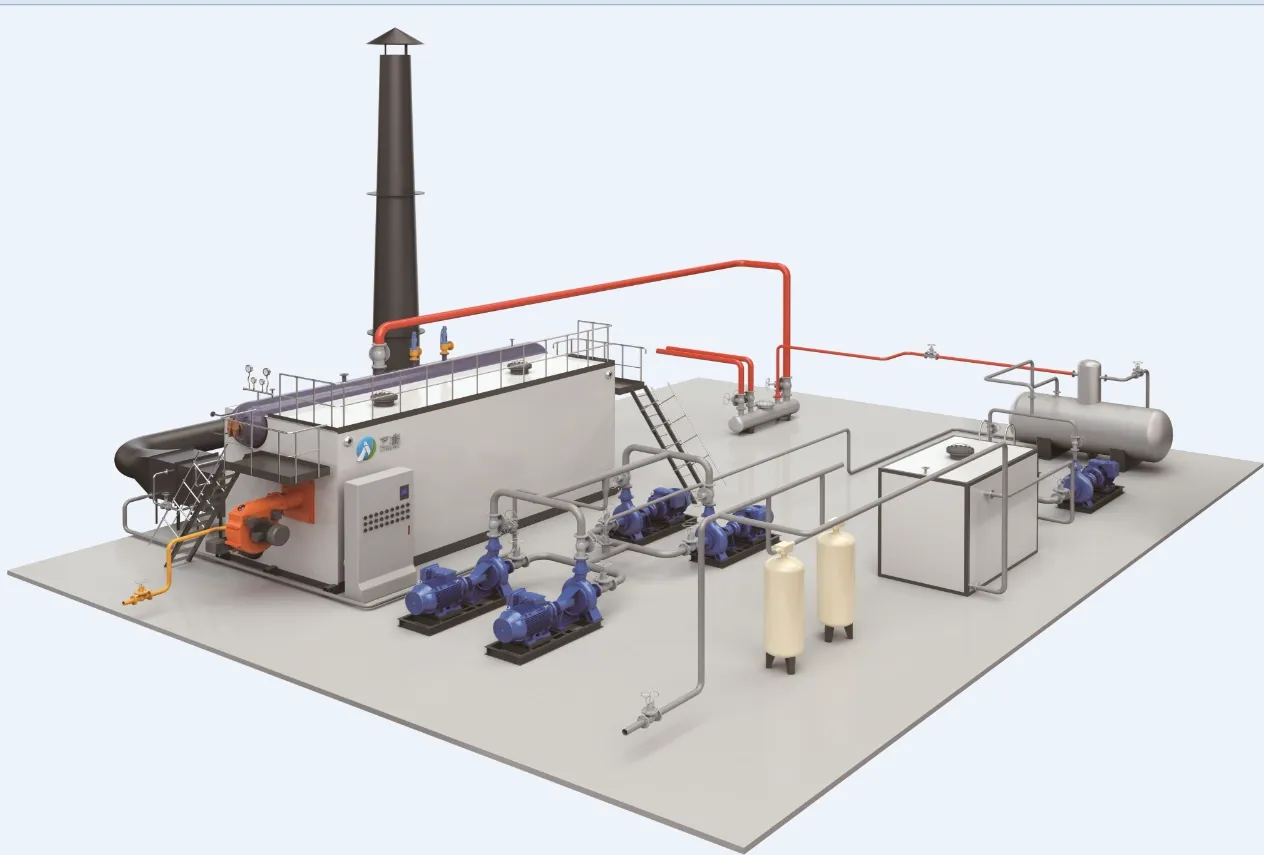

In industrial applications, thermal oil boilers play a pivotal role in providing efficient heat transfer for a variety of processes. Among the diverse types of boilers available, the fixed grate thermal oil boiler stands out for its unique design and operational benefits. This article explores the key features, advantages, and applications of fixed grate thermal oil boilers, underscoring their significance in the energy sector.

What is a Fixed Grate Thermal Oil Boiler?

A fixed grate thermal oil boiler is a type of boiler that uses thermal oil as a heat transfer medium instead of water. This design allows for higher operating temperatures and pressure levels, making these boilers suitable for a variety of industrial applications. The “fixed grate” refers to a stationary combustion surface where solid fuels, such as coal, biomass, or other organic materials, are burned to produce heat.

Key Features

1. Heat Transfer Efficiency Fixed grate thermal oil boilers are designed to achieve optimal heat transfer. The thermal oil can operate at temperatures ranging from 150°C to 350°C, facilitating efficient energy use in processes that require high temperatures.

2. Fuel Versatility These boilers can utilize a wide range of solid fuels, making them a versatile choice for many industries. Depending on the availability of resources and cost considerations, businesses can choose the most suitable fuel type.

3. Efficiency and Economy With a solid fuel combustion system, fixed grate boilers are known for their higher thermal efficiency, which can lead to reduced operational costs. The efficient use of heat results in lower fuel consumption and minimized emissions.

4. Durability and Low Maintenance Built with robust materials, fixed grate thermal oil boilers typically exhibit long service life and lower maintenance requirements, which contributes to overall operational reliability.

fixed grate thermal oil boiler company

Advantages

1. Operational Flexibility The ability to use various types of solid fuels provides operational flexibility. Companies can adapt to changes in fuel availability and prices, supporting economic sustainability.

2. High Temperature Capabilities Thermal oil systems can achieve higher temperatures without the risk of boiling, unlike conventional water-based systems. This characteristic makes them ideal for applications in sectors that demand precision heating.

3. Environmental Compliance Modern fixed grate thermal oil boilers are designed to meet stringent environmental regulations. With advancements in combustion technology, these systems can effectively reduce emissions of particulate matter and other pollutants.

4. Compact Design Many fixed grate thermal oil boilers come in compact designs, optimizing space without compromising on performance. This feature is particularly beneficial for facilities with limited installation areas.

Applications

Fixed grate thermal oil boilers find applications across various industries, including

- Chemical Processing Used for providing heat in chemical reactions and distillation processes. - Textile Industry Essential for heat setting, drying, and dyeing processes. - Food Processing Employed in pasteurization, cooking, and drying operations. - Wood Processing Utilized for drying wood products and in processing plants.

In conclusion, fixed grate thermal oil boilers represent a vital component of modern industrial heating. Their efficiency, versatility, and environmental compliance make them a favorable choice for businesses across multiple sectors. As industries continue to seek sustainable and cost-effective heating solutions, fixed grate thermal oil boilers will remain at the forefront, contributing significantly to enhanced operational efficiency and environmental stewardship. With advancements in technology and design, the future looks promising for these robust heating systems.

-

High-Efficiency OEM Steam Boilers w/GPT-4-TurboNewsAug.02,2025

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025