custom horizontal steam boiler

Custom Horizontal Steam Boiler A Comprehensive Overview

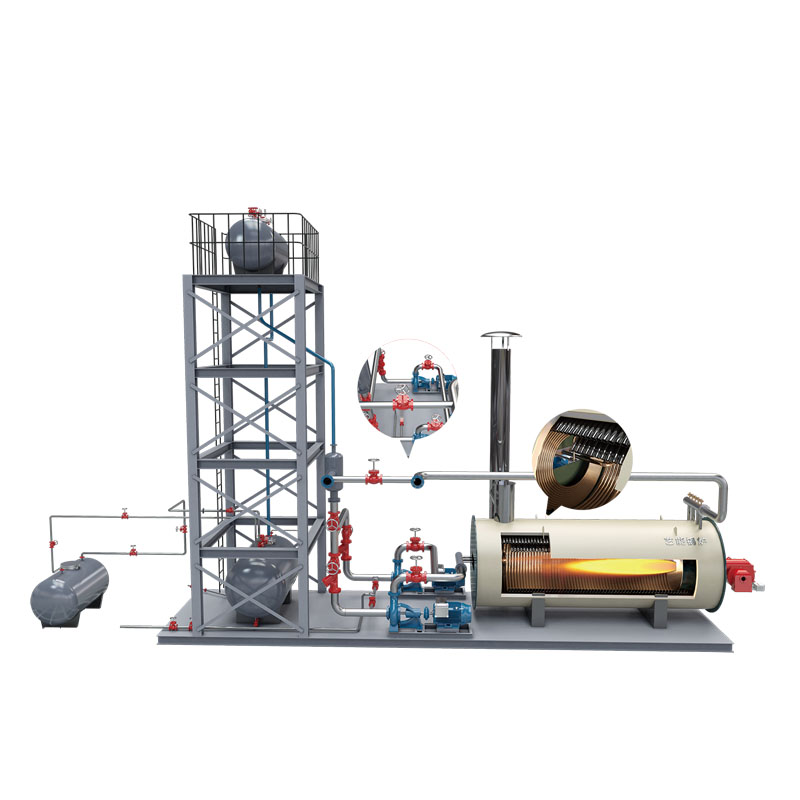

In industrial applications, the demand for efficient steam generation is paramount. One solution that has gained popularity is the custom horizontal steam boiler. These boilers are designed to meet specific client needs while offering flexibility, efficiency, and reliability in steam production. This article delves into the characteristics, advantages, and applications of custom horizontal steam boilers.

Understanding Horizontal Steam Boilers

A horizontal steam boiler is a type of boiler where the main components are positioned horizontally. This design allows for a substantial steam-holding capacity, making them an excellent choice for various industrial processes. Customization options enable manufacturers to tailor these boilers to a company's unique requirements, ensuring they operate at peak efficiency under specific conditions.

Design and Construction

The construction of a horizontal steam boiler typically involves robust materials such as carbon steel or stainless steel to withstand high pressure and temperature. The boiler consists of several key components a shell, tubes, a burner, and a control system. The shell contains the water to be heated, and the tubes allow for the effective exchange of heat generated by combustion. Customization can alter dimensions, pressure ratings, and materials based on the operational parameters required by different industries.

Advantages of Custom Horizontal Steam Boilers

1. Tailored Solutions One of the primary advantages of custom horizontal steam boilers is their adaptability. By customizing the design, manufacturers can ensure that the boiler operates efficiently within the specific constraints of a business, such as steam load requirements, fuel types, and operational settings.

2. Space Efficiency The horizontal design is often space-saving compared to vertical boilers, which can require more vertical clearance. This design makes them easier to fit into various industrial layouts, facilitating the integration of steam systems into existing infrastructures.

custom horizontal steam boiler

3. Ease of Maintenance Horizontal steam boilers typically allow easier access to internal components for inspection and maintenance. This feature can significantly reduce downtime and prolong the lifespan of the boiler, ensuring that steam availability remains consistent.

4. Operational Efficiency With modern technological advancements, custom horizontal steam boilers can be equipped with high-efficiency burners and advanced control systems. These technologies not only improve fuel efficiency but can also reduce emissions, leading to a more eco-friendly operation.

5. Scalability As business needs grow, so too can the steam system. Custom horizontal steam boilers can be designed with scalability in mind, allowing companies to expand their steam generation capacity without a complete overhaul of existing systems.

Applications

Custom horizontal steam boilers are versatile and can be utilized in various industries, such as

- Food Processing In this sector, consistent and high-quality steam is essential for cooking, cleaning, and processing food products. - Chemical Manufacturing Steam is often used in chemical processes; having a reliable source ensures that production remains uninterrupted. - Textile Industry Steam is crucial in the dyeing and finishing processes, making horizontal steam boilers an integral part of textile production. - Power Generation Many power plants use steam boilers to generate electricity, often requiring custom specifications to meet energy demands.

Conclusion

In conclusion, custom horizontal steam boilers are an essential component of many industrial operations. Their unique design, coupled with the ability to tailor specifications to meet specific needs, positions them as a highly efficient solution for steam generation. Industries ranging from food processing to chemical manufacturing benefit greatly from the scalability, operational efficiency, and ease of maintenance that these boilers offer. As the demand for customized and efficient industrial solutions continues to grow, the role of custom horizontal steam boilers will undoubtedly expand, driving innovation and enhancing productivity across multiple sectors. Investing in these sophisticated systems is not just investing in a boiler; it’s a commitment to achieving operational excellence and sustainability in an increasingly competitive market.

-

Efficient Thermal Oil Boilers with AI Optimization | Superior PerformanceNewsAug.03,2025

-

High-Efficiency OEM Steam Boilers w/GPT-4-TurboNewsAug.02,2025

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025