old steam boiler service

The Importance of Regular Service for Old Steam Boilers

Steam boilers have been a cornerstone of industrial processes and heating systems for over a century. These systems, particularly the older models, require meticulous care and attention to ensure they operate safely and efficiently. In this article, we will discuss the significance of regular service for old steam boilers and the implications of neglecting maintenance.

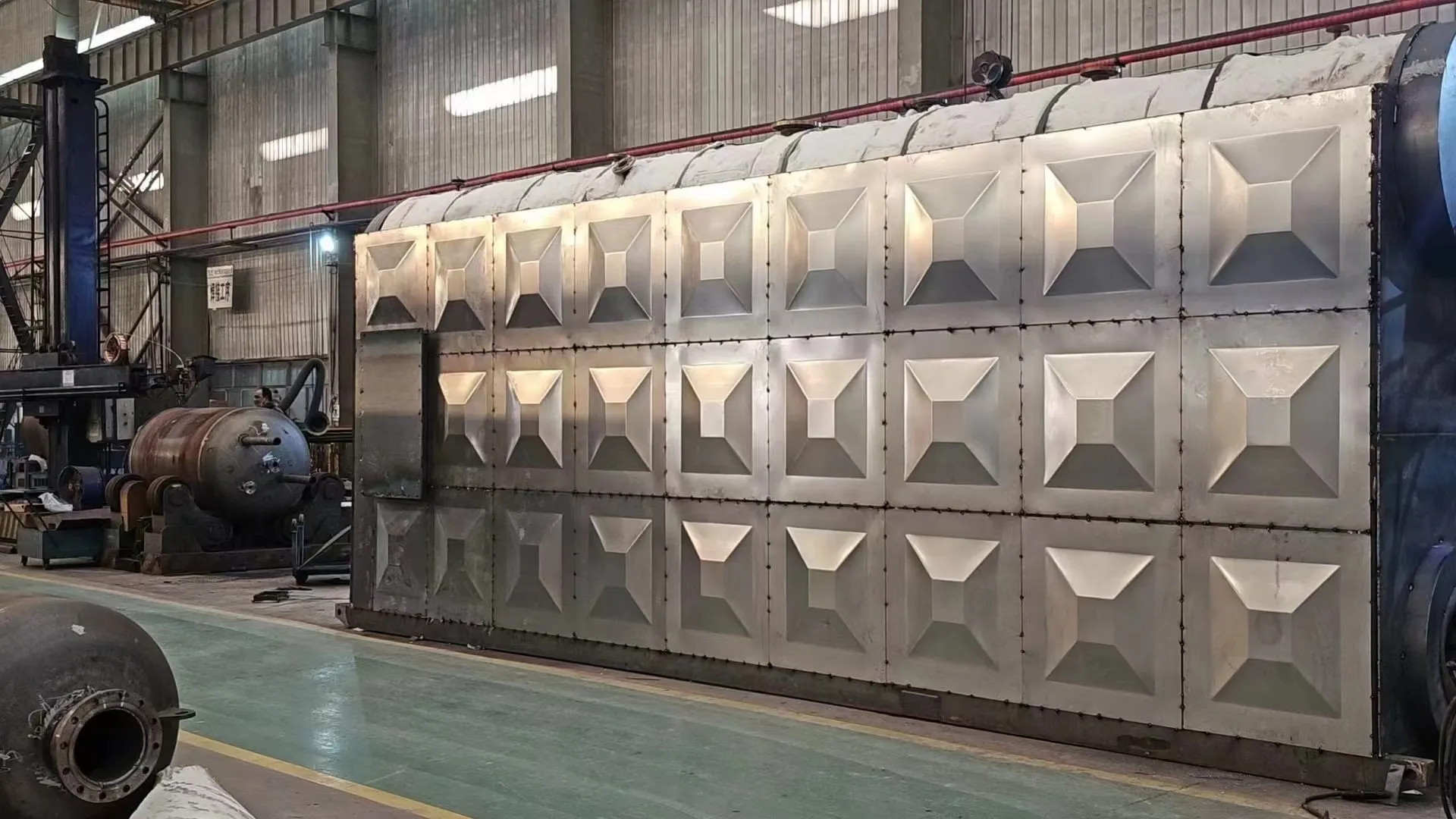

Understanding Old Steam Boilers

Old steam boilers, typically characterized by their robust construction and simplistic design, were built to last. However, with age, these systems become vulnerable to wear and tear. Factors such as corrosion, sediment buildup, and mechanical failures can compromise their performance, leading to inefficiencies and potential safety hazards. Unlike modern boilers equipped with advanced monitoring technology, older models rely heavily on routine maintenance to function optimally.

Why Regular Service is Essential

One of the primary reasons for servicing old steam boilers is safety. Aging components can lead to dangerous malfunctions, including explosions or gas leaks. Regular inspections help identify potential issues before they escalate. Certified technicians examine crucial elements such as pressure relief valves, steam traps, and water quality to ensure they meet safety standards.

2. Efficiency Optimization

Old steam boilers can become less efficient as they age, consuming more fuel and producing less steam. Regular servicing involves cleaning boiler tubes, checking for leaks, and recalibrating controls. These tasks help restore optimal efficiency, which not only enhances performance but also reduces operational costs over time.

old steam boiler service

3. Prolonging Equipment Life

Investing in regular maintenance can significantly extend the lifespan of an old steam boiler. By addressing minor issues promptly, operators can avoid costly repairs and replacements down the line. Scheduled servicing includes thorough inspections and routine replacements of worn parts, ultimately preserving the integrity of the boiler.

4. Compliance with Regulations

In many regions, regulations mandate regular inspections and maintenance of boiler systems to ensure compliance with safety and environmental standards. Failing to adhere to these regulations can result in fines and increased scrutiny from regulatory bodies. Regular service helps ensure that old steam boilers meet all necessary operational and safety requirements.

5. Energy Efficiency Incentives

With the growing emphasis on sustainability and energy efficiency, many governments and organizations offer incentives for maintaining and upgrading old steam technology. Routine servicing can qualify facilities for rebates and financial aid, making it economically advantageous to invest in maintenance programs.

Conclusion

In summary, the service of old steam boilers is of paramount importance for safety, efficiency, equipment longevity, regulatory compliance, and energy savings. Plant managers and facility operators must recognize the value of regular inspections and maintenance not just as a compliance requirement, but as an essential practice that safeguards personnel and assets while improving the reliability of operations. Investing time and resources into the upkeep of these systems is not only a smart decision but a necessary one to ensure they continue to meet the demands of modern industry. By prioritizing proper maintenance, operators can ensure that their old steam boilers remain both a vital component of their infrastructure and safe to operate for years to come.

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025