Boilers for Asphalt Emulsion Production in Manufacturing Facilities

The Role of Boilers in Asphalt Emulsion Manufacturing

Asphalt emulsion is a vital material in the construction and maintenance of roads, parking lots, and various infrastructure. Its production is a complex process that requires precision and the right equipment to ensure quality and efficiency. One of the most critical components in this process is the boiler, which plays a foundational role in providing the necessary heat and maintaining the ideal conditions for asphalt emulsion manufacturing.

Understanding Asphalt Emulsion

Asphalt emulsion is a mixture of asphalt cement, water, and an emulsifying agent. The emulsifying agent helps to blend the asphalt with water to form a stable emulsion that can be effectively applied in various applications, such as paving and sealing. The quality of the final product heavily depends on the properties of each raw material and the conditions under which they are combined. This is where the role of the boiler becomes crucial.

The Importance of Boilers

Boilers are essential for generating steam or hot water required in several stages of the asphalt emulsion production process. The heat provided by the boiler serves multiple purposes

1. Heating of Asphalt and Water Before emulsification, asphalt and water must be heated to specific temperatures. Heating the asphalt ensures its viscosity is appropriate for mixing, while warm water facilitates the emulsification process, helping to disperse the liquid asphalt. The boiler allows for the precise heating of these materials, which is critical to achieving a stable emulsion.

2. Steam Generation In many asphalt emulsion production facilities, steam is utilized for various processes, including maintaining temperatures and cleaning the equipment. The consistent supply of steam from the boiler ensures that production can continue without interruptions, which is vital for meeting demand and minimizing downtime.

3. Energy Efficiency Modern boilers are designed to be energy efficient. They utilize advanced technology to minimize fuel consumption while maximizing output. This is particularly significant in the asphalt emulsion industry, where the cost of energy represents a considerable portion of manufacturing expenses. Investing in a high-efficiency boiler can lead to substantial savings over time.

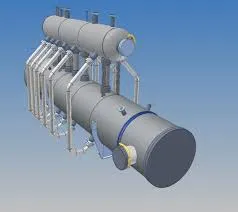

boiler for asphalt emulsion manufacturers

4. Environmental Considerations With increasing regulatory constraints regarding emissions and environmental sustainability, the choice of boiler technology is more critical than ever. Manufacturers are now turning to boilers that comply with emission regulations and are capable of utilizing alternative fuels, further enhancing their sustainability and reducing their carbon footprint.

Choosing the Right Boiler

When selecting a boiler for asphalt emulsion manufacturing, several factors should be considered

- Capacity The boiler must have adequate capacity to support the production volume of the facility. It should be able to generate sufficient steam or hot water to meet peak demand.

- Fuel Type The choice of fuel can significantly impact operational costs and emissions. Options include natural gas, oil, or biomass, and manufacturers must consider the availability and costs of these fuels in their region.

- Efficiency Look for boilers with high-efficiency ratings to ensure that energy consumption is minimized. This not only reduces costs but also has a positive impact on the environment.

- Maintenance Regular maintenance is crucial for efficient operation. Opt for boilers that are easy to maintain and have good support from manufacturers for parts and service.

Conclusion

In conclusion, boilers are a critical component of the asphalt emulsion manufacturing process. They provide the necessary heat and steam essential for producing high-quality emulsions. As environmental concerns rise, the industry is moving toward more energy-efficient and sustainable boiler technologies, making it crucial for manufacturers to invest wisely. By choosing the right boiler system, asphalt emulsion manufacturers can ensure their operations remain efficient, cost-effective, and environmentally friendly while meeting the demands of their customers.

-

High-Efficiency OEM Steam Boilers w/GPT-4-TurboNewsAug.02,2025

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025