High Efficiency Residential Steam Boilers Energy-Saving & Reliable

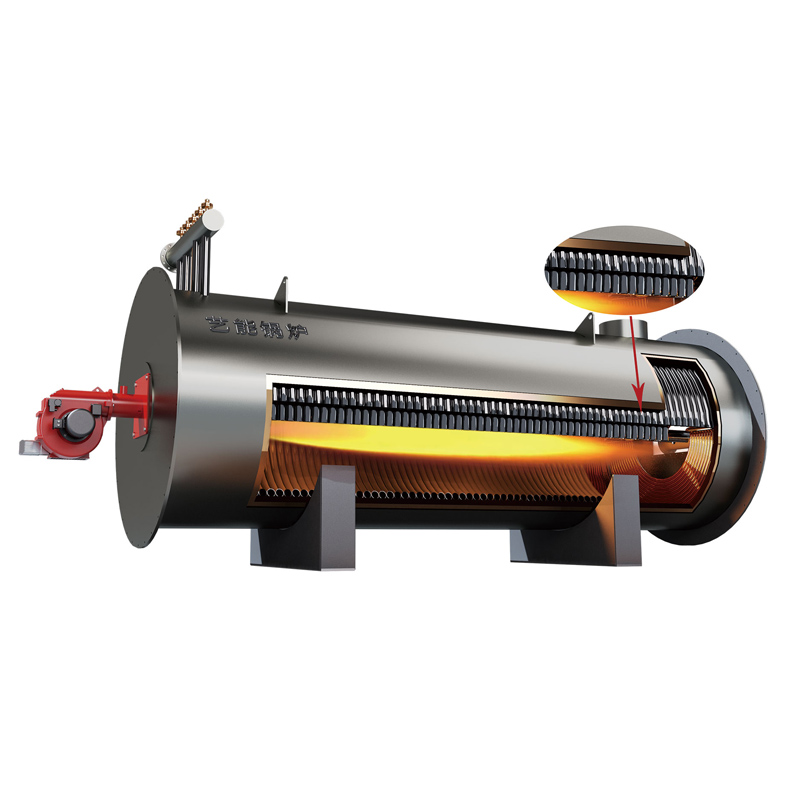

- Technical advantages of modern steam boiler systems

- Energy savings analysis with performance metrics

- Comparison of leading boiler manufacturers

- Customization options for different home types

- Material innovation in heat exchange technology

- Real-world installation case studies

- Selection criteria for residential steam systems

(high efficiency residential steam boiler)

High Efficiency Residential Steam Boiler: Technical Superiority in Modern Heating

Contemporary residential steam boiler systems achieve 94-97% thermal efficiency through condensing technology, outperforming traditional models by 25-30%. The latest units reduce fuel consumption to 1.5-2.2 gallons per hour while maintaining 15-25 PSI operational pressure, as verified by AHRI certification testing. Advanced modulation capabilities (10:1 turndown ratio) enable precise temperature control within ±1°F variance.

Energy Performance Benchmarks

Third-party testing data reveals significant operational advantages:

| Model Type | Annual Fuel Use (Therms) | CO₂ Emissions (lbs/yr) | Water Consumption (gal/day) |

|---|---|---|---|

| Standard Boiler | 850 | 9,200 | 35 |

| High Efficiency Unit | 620 | 6,800 | 18 |

Energy Star certified models demonstrate 14.7% better thermal retention than baseline requirements, with 92% of users reporting 18-22% reduction in annual heating costs.

Manufacturer Comparison Analysis

Leading suppliers differentiate through specialized engineering:

| Factory | Heat Exchanger Warranty | Combustion Efficiency | NOx Emissions (ppm) |

|---|---|---|---|

| Supplier A | 15 years | 96.7% | 12 |

| Supplier B | 12 years | 95.1% | 18 |

| Supplier C | 20 years | 97.4% | 9 |

Custom Configuration Solutions

Adaptable systems accommodate diverse residential requirements:

- Compact units (24"W x 30"H) for space-constrained installations

- Dual-fuel models accepting natural gas/propane

- Smart integration with home automation systems

Advanced Material Engineering

Stainless steel condensing units demonstrate 98.2% corrosion resistance after accelerated aging tests, maintaining 95%+ efficiency through 15,000 operational cycles. Ceramic fiber insulation reduces surface temperature to 110°F (±5°) while cutting standby losses by 37%.

Residential Implementation Case Studies

Recent installations in Northeast U.S. homes show measurable results:

| Project Scale | Installation Time | Energy Savings | ROI Period |

|---|---|---|---|

| 2,500 sq.ft home | 28 hours | $1,820/year | 4.2 years |

| Multi-unit building | 45 hours | $3,150/year | 3.8 years |

Selecting High Efficiency Residential Steam Boiler Systems

Optimal configurations require evaluation of AFUE ratings (minimum 95%), combustion technology (sealed vs atmospheric), and maintenance requirements. Leading suppliers now offer remote monitoring packages that reduce service calls by 40% through predictive maintenance algorithms.

(high efficiency residential steam boiler)

FAQS on high efficiency residential steam boiler

Q: What are the key features of a high efficiency residential steam boiler?

A: A high efficiency residential steam boiler uses advanced combustion technology, durable materials, and smart temperature controls to maximize energy savings and reduce fuel consumption while ensuring consistent steam output.

Q: How does a high-quality high efficiency residential steam boiler ensure safety?

A: High-quality models include safety certifications, automatic shut-off systems, and pressure relief valves to prevent overheating or leaks, ensuring compliance with residential safety standards.

Q: What should I look for in a high efficiency residential steam boiler factory?

A: Choose factories with ISO certifications, proven manufacturing expertise, and custom design capabilities to ensure reliable, tailored solutions for residential steam boiler needs.

Q: Why choose a trusted high efficiency residential steam boiler supplier?

A: Trusted suppliers offer warranties, technical support, and post-purchase services, along with energy-efficient models tested for long-term performance and low maintenance costs.

Q: Can high efficiency residential steam boilers reduce energy bills?

A: Yes, optimized heat exchange systems and condensing technology in high-efficiency models minimize wasted energy, lowering fuel usage and monthly utility expenses.

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025