Top Manufacturers of Hot Conduction Oil Boilers for Efficient Thermal Solutions

The Rise of Hot Conduction Oil Boiler Manufacturers

In the ever-evolving landscape of industrial heating solutions, hot conduction oil boilers have gained significant attention for their efficiency and versatility. These systems utilize a specialized heat transfer fluid to achieve high-temperature operations while ensuring minimal energy loss. As industries increasingly seek reliable and efficient heating methods, the demand for hot conduction oil boilers has surged, prompting a wave of innovation and competition among manufacturers.

What Are Hot Conduction Oil Boilers?

Hot conduction oil boilers operate by heating a specialized thermal oil, which transfers heat to various production processes. Unlike traditional water-based boilers, these systems can reach temperatures exceeding 300°C without pressurizing, making them ideal for applications requiring precise temperature control at high levels. The thermal oil circulates through a closed-loop system, delivering heat efficiently while minimizing the risk of energy loss.

Advantages of Hot Conduction Oil Boilers

One of the pivotal advantages of hot conduction oil boilers is their efficiency. By utilizing thermal oil, these systems can achieve higher operating temperatures, which is particularly beneficial for industries such as chemical processing, food production, and textile manufacturing. Furthermore, the heat transfer fluid’s stability at elevated temperatures allows for longer operational life and reduced maintenance costs.

Another compelling aspect is energy savings. Hot conduction oil boilers typically operate at lower costs due to their reduced fuel consumption and high thermal efficiency. Moreover, the ability to operate at lower pressures enhances safety, reducing the risks associated with steam boilers, such as explosions or leaks.

Market Dynamics

The growing industrialization and the rise of energy-efficient solutions have led to an increase in the number of hot conduction oil boiler manufacturers. Companies are investing in research and development to enhance the efficiency and efficiency of their products. Moreover, manufacturers are increasingly focusing on sustainability, developing eco-friendly thermal oils and systems designed to minimize environmental impact.

The competitive landscape varies from established giants to innovative startups. Established manufacturers benefit from their experience and reputation, often developing advanced technologies and custom solutions tailored to complex industrial needs. Conversely, new entrants are challenging the status quo by offering streamlined, cost-effective solutions and leveraging cutting-edge technologies, such as digital monitoring and automation.

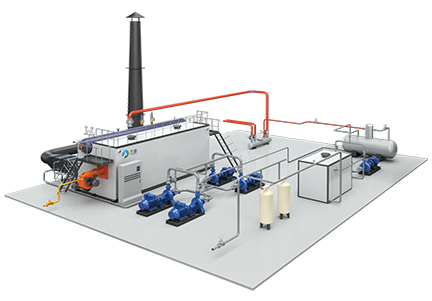

hot conduction oil boiler manufacturers

Key Considerations When Choosing a Manufacturer

When selecting a hot conduction oil boiler manufacturer, several factors must be considered

1. Experience and Reputation Look for manufacturers with a proven track record in the industry. Experience often translates into reliability and better service.

2. Customization Options Different industries have unique needs. A manufacturer should offer customizable solutions to meet specific heating requirements.

3. Technical Support and Service Ensure the manufacturer provides excellent after-sales support, including installation, maintenance, and technical assistance.

4. Compliance with Regulations It’s essential to choose manufacturers that comply with industry standards and regulations, ensuring the safety and reliability of the equipment.

5. Sustainability Practices As businesses strive to reduce their carbon footprint, selecting manufacturers committed to environmentally friendly practices can enhance a company's sustainability profile.

Conclusion

The market for hot conduction oil boilers continues to grow, driven by the demand for efficient and safe heating solutions in various industries. With an increasing number of manufacturers entering the space, businesses have more options than ever. By carefully considering the factors outlined above, industries can select reliable partners that will support their heating needs efficiently and sustainably, ultimately enhancing their overall operational efficacy. As technology advances, hot conduction oil boilers are poised to play a crucial role in heating applications for years to come.

-

High-Efficiency House Hot Water Boiler Supplier & Factory Reliable House Hot Water Boiler Product SolutionsNewsJul.04,2025

-

Top Boiler Dealer & Supplier Quality Boiler Dealer Products from Factory DirectNewsJul.04,2025

-

High-Efficiency Waste Heat Recovery Boiler Expert Service & QuotesNewsJul.04,2025

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025