odm boiler steam

Understanding ODM Boiler Steam A Comprehensive Overview

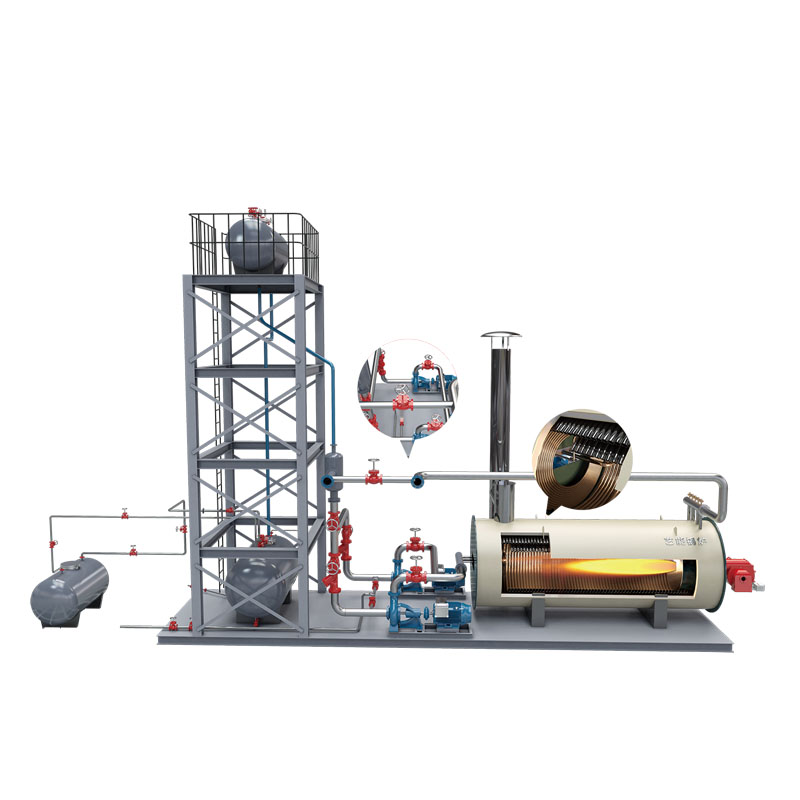

In the industrial landscape, steam plays a pivotal role across various applications, from heating processes to power generation. Among the technologies that harness this essential resource are boilers, specifically those classified under the category of ODM (Original Design Manufacturer). This article aims to explore the intricacies of ODM boiler steam systems, their advantages, applications, and essential maintenance requirements.

What is ODM Boiler Steam?

ODM boiler steam refers to steam produced by boilers that are designed and manufactured by Original Design Manufacturers. These manufacturers often tailor their products to meet the specific needs of their clients while adhering to industry standards and regulations. The versatility of ODM boilers allows for customization in size, capacity, and functionality, making them suitable for various industrial applications.

The steam generated by these boilers can be utilized in multiple sectors, including manufacturing, food processing, chemical production, and energy generation. The ability to produce steam on demand makes ODM boiler systems particularly valuable in industries where efficiency and uptime are critical.

Advantages of ODM Boiler Steam Systems

1. Customization One of the standout features of ODM boilers is their ability to be customized. Clients can request specific designs and functionalities that cater to unique operational requirements. This customization ensures that businesses can optimize processes and improve productivity.

2. Efficiency ODM boilers typically incorporate advanced technologies aimed at maximizing energy efficiency. Innovations such as heat recovery systems allow these boilers to utilize waste heat, thereby reducing overall fuel consumption and lowering operational costs.

3. Quality Assurance Since ODM manufacturers often specialize in boiler design, they maintain stringent quality control measures during production. This ensures that the boilers meet safety standards and perform reliably over their lifespan.

4. Scalability As businesses grow, their steam requirements can change. ODM boilers can be designed to scale alongside a company's needs, allowing for easy upgrades and modifications without the need for complete system replacements.

5. Technological Integration Modern ODM boilers are often equipped with smart technologies, enabling real-time monitoring and automation. This not only helps in optimizing steam production but also in predictive maintenance, reducing downtime.

Applications of ODM Boiler Steam

odm boiler steam

The applications of ODM boiler steam are vast and varied. In the manufacturing sector, steam is crucial for processes like sterilization, cooking, and drying. In the food industry, for instance, steam is used in pasteurization and to ensure food safety.

Similarly, in the chemical industry, steam is essential for maintaining reaction temperatures and providing energy for distillation processes. Energy generation plants also rely on boiler steam to drive turbines, converting thermal energy into electrical energy.

Maintenance of ODM Boiler Systems

To ensure the longevity and efficiency of ODM boiler systems, regular maintenance is crucial. Key maintenance practices include

1. Regular Inspections Periodic assessments by qualified personnel can help identify potential issues before they escalate. Inspections should focus on key components like pressure vessels, pumps, and safety valves.

2. Water Quality Management The quality of water used in boilers significantly impacts their performance and longevity. Impurities can cause scaling and corrosion. Therefore, treating and monitoring water quality is vital.

3. Cleaning and Descaling Over time, sludge and scale can build up inside the boiler. Regular cleaning and descaling procedures should be conducted to maintain heat transfer efficiency.

4. Monitoring System Performance Implementing monitoring systems can provide insights into the operational status of the boiler. This data can be invaluable for timely interventions.

5. Adherence to Regulations Ensuring compliance with industry standards and regulations not only promotes safety but also enhances the operational reliability of boiler systems.

Conclusion

ODM boiler steam systems represent a critical component of various industrial applications, delivering customized, efficient, and reliable steam solutions. As industries continue to evolve, the significance of tailored boiler systems will only grow, reflecting the ongoing demand for efficiency, safety, and performance. Proper maintenance and attention to operational needs will ensure that these systems continue to contribute positively to the sectors they serve.

-

Top Electric Steam Boiler Manufacturers | AI EfficiencyNewsAug.04,2025

-

Efficient Thermal Oil Boilers with AI Optimization | Superior PerformanceNewsAug.03,2025

-

High-Efficiency OEM Steam Boilers w/GPT-4-TurboNewsAug.02,2025

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025