Best Boiler for Bitumen Emulsifying | Efficient Heating Solutions

The Best Boiler for Bitumen Emulsifying

When it comes to the construction and maintenance of roads, highways, and rooftops, bitumen emulsification plays a crucial role. Bitumen emulsions are essential for asphalt production and maintenance. To achieve the best results in emulsifying bitumen, selecting the right boiler is vital. Here, we will explore the features that make a boiler the best for this application.

First and foremost, efficiency is a key factor. A high-efficiency boiler uses less fuel to generate the same amount of heat, which not only reduces operational costs but also minimizes environmental impact. Look for boilers with high thermal efficiency ratings, ideally above 90%. This efficiency ensures that the temperature required for emulsifying bitumen can be achieved quickly and maintained consistently.

Temperature control is another critical aspect. Bitumen emulsification requires precise temperature management to create the right consistency and properties in the emulsion. A boiler equipped with advanced temperature control technology, such as modulating burners and integrated thermostatic controls, will ensure that the heating process is stable and precise. This level of control helps in achieving uniform emulsification, resulting in higher quality asphalt mixtures.

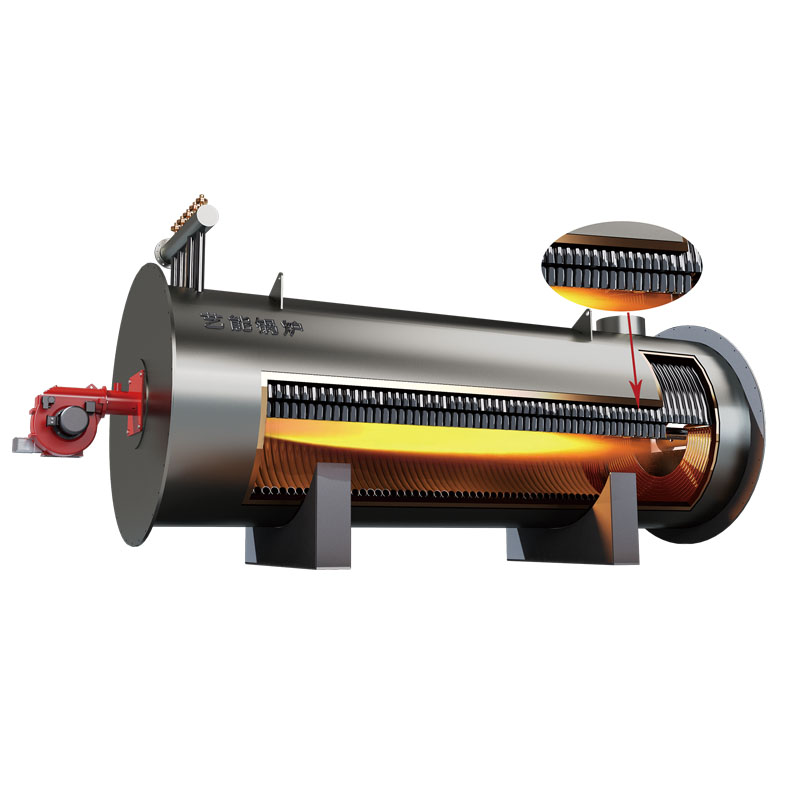

best boiler for bitumen emulsifying

The type of boiler is also important. Research indicates that steam boilers and hot water boilers are both suitable for bitumen emulsifying. Steam boilers provide quick heat generation, which can be beneficial in processes requiring rapid temperature changes. On the other hand, hot water boilers might be preferable for their energy efficiency and lower pressure operations. Choosing between these types depends on the specific requirements of the emulsification process and the scale of production.

Another consideration is the boiler's build quality and durability. Bitumen emulsification can be harsh on equipment due to the nature of the materials involved. A boiler made from high-quality, corrosion-resistant materials will ensure longevity and reliability, reducing maintenance costs over time.

Lastly, consider the boiler's compatibility with automation systems. Many modern emulsification processes benefit from automated control systems that optimize performance. A boiler that can integrate seamlessly with these systems will enhance operational efficiency and allow for real-time monitoring of conditions.

In conclusion, when selecting the best boiler for bitumen emulsifying, focus on efficiency, temperature control, type, durability, and compatibility with automation. Investing in a high-quality boiler tailored to these needs will contribute to the production of superior bitumen emulsions, ultimately leading to better asphalt performance and longer-lasting infrastructure.

-

Coal Fired Thermal Oil Heater Supplier Efficient & Durable Industrial Heating SolutionsNewsMay.18,2025

-

Organic Heating Transfer Material Boiler Supplier & Factory High-EfficiencyNewsMay.18,2025

-

Skid Mounted Thermal Oil Boilers Efficient & Compact Design ExporterNewsMay.17,2025

-

Bangkok Industrial Boiler Supplier High-Efficiency Solutions & Factory DirectNewsMay.17,2025

-

Best Home Heating Hot Water Boiler Reliable Exporter & Affordable PricesNewsMay.17,2025

-

High Efficiency Residential Steam Boilers Energy-Saving & ReliableNewsMay.16,2025