waste heat recovery boiler manufacturers product

Waste Heat Recovery Boiler Manufacturers Harnessing Energy Efficiency

In today's world, energy efficiency has become a critical focus for industries looking to minimize costs and reduce environmental impact. One of the most effective ways to enhance energy efficiency is through waste heat recovery (WHR) systems. At the heart of many WHR systems are waste heat recovery boilers, which play a vital role in capturing excess heat generated during industrial processes and converting it into useful energy. This article delves into the significance of waste heat recovery boiler manufacturers, the technology involved, and the benefits they bring to various sectors.

Understanding Waste Heat Recovery Boilers

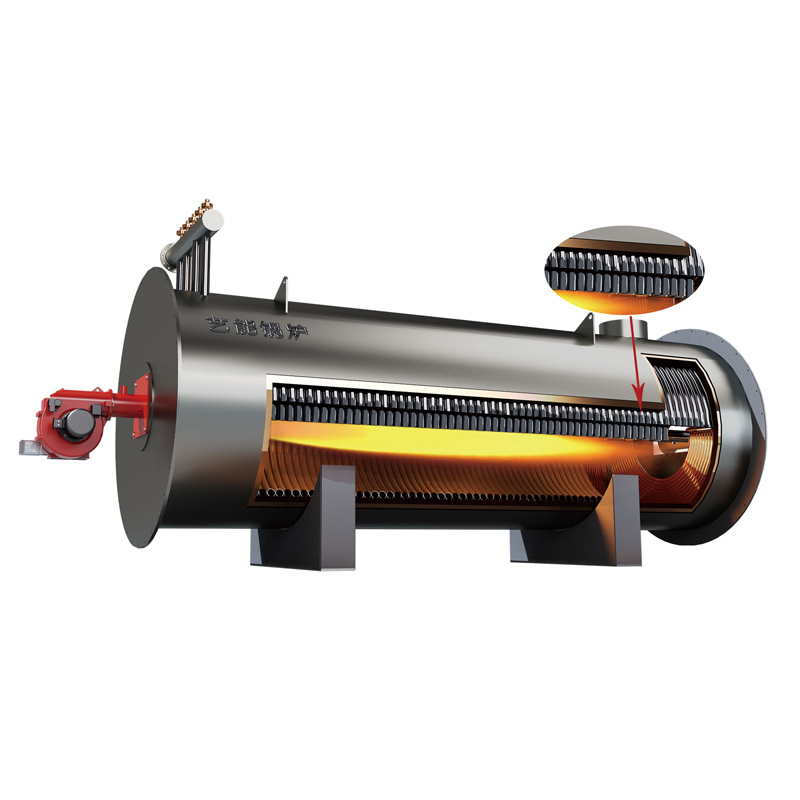

A waste heat recovery boiler is designed to utilize waste heat from various processes, such as combustion engines, industrial furnaces, and chemical processes. This excess heat, which would typically be released into the atmosphere as waste, can be harnessed and used to preheat water, produce steam, or generate electricity. The primary components of a waste heat recovery boiler include a heat exchanger, blowers, and control systems that ensure optimal operation and efficiency.

Waste heat recovery boilers are categorized based on the type of heat sources they recover from, including flue gases, process heat, and hot liquids. The choice of boiler depends on the specific requirements of the application and the nature of the waste heat available.

The Role of Manufacturers

The role of waste heat recovery boiler manufacturers is vital in enabling industries to adopt this technology effectively. These manufacturers design and fabricate bespoke solutions tailored to the specific needs of their clients, ensuring maximum efficiency and reliability. Key players in this field focus on continuous innovation, employing advanced materials and engineering practices to enhance the performance of their boilers.

Leading manufacturers also conduct extensive research and development (R&D) to keep pace with evolving industry standards, improving their products' efficiency and durability. Partnerships with engineering firms and industry experts allow these manufacturers to incorporate the latest technological advancements and best practices into their designs.

Advantages of Waste Heat Recovery Boilers

waste heat recovery boiler manufacturers product

1. Energy Cost Savings One of the most significant advantages of deploying waste heat recovery boilers is the considerable reduction in energy costs. By recycling waste heat, industries can lower their fuel consumption, resulting in significant savings over time.

2. Environmental Benefits Reducing energy consumption directly benefits the environment. By optimizing energy use, waste heat recovery systems decrease greenhouse gas emissions and other pollutants, aligning with global sustainability goals.

3. Increased System Efficiency Integrating a waste heat recovery boiler into existing processes can enhance overall system efficiency. It allows industries to leverage their energy resources fully, thereby improving the return on investment (ROI) for energy expenditures.

4. Regulatory Compliance As governments worldwide tighten regulations regarding emissions and energy use, waste heat recovery systems help industries comply with these standards. Utilizing waste heat can significantly reduce the environmental footprint, making it easier for companies to meet regulatory requirements.

5. Versatility Across Industries Waste heat recovery boiler technology is applicable across a range of sectors, including manufacturing, petrochemicals, power generation, and food processing. This versatility allows various industries to access these benefits and tailor solutions that fit their specific processes.

6. Enhanced Reliability and Lifespan Modern waste heat recovery boilers are built using durable materials and advanced engineering techniques, ensuring a longer operational lifespan and minimal maintenance downtime. This reliability contributes to ongoing energy savings and operational efficiency.

Conclusion

As industries continue to seek ways to enhance energy efficiency and reduce operational costs, the importance of waste heat recovery boiler manufacturers cannot be overstated. By providing innovative technology and robust solutions, these manufacturers are at the forefront of an energy revolution that aims to turn waste into value.

Investing in waste heat recovery systems not only makes economic sense but also contributes to a more sustainable future. As technology advances, we can expect to see even more efficient and effective solutions from manufacturers, further embedding waste heat recovery as a fundamental practice in modern industrial operations. This shift towards energy recovery and sustainability is essential for industries looking to thrive in an increasingly competitive and environmentally conscious world.

-

Industrial Steam Boiler Corporation - Reliable Industrial Boiler Manufacturer & SupplierNewsJul.08,2025

-

High-Efficiency Steam Boiler Heat Exchanger Supplier & Factory Durable Products for IndustryNewsJul.08,2025

-

Premium Electric Steam Boiler Manufacturer Reliable Company & Factory SolutionsNewsJul.08,2025

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025