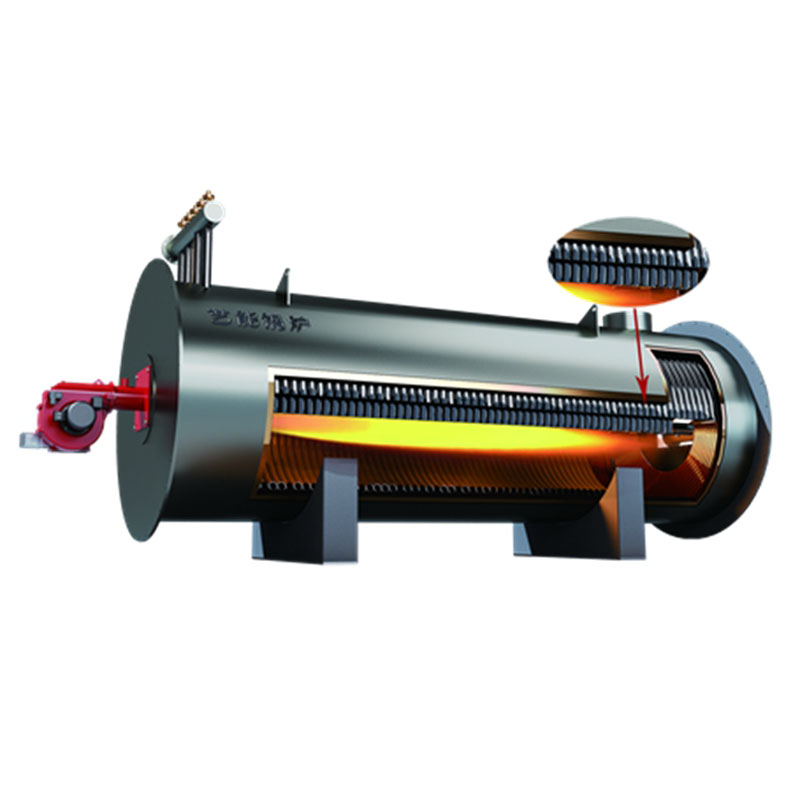

automatic feeding thermal oil boiler product

The Advantages of Automatic Feeding Thermal Oil Boilers

In today’s industrial landscape, maintaining efficient energy systems is paramount for operational success. One innovation that has emerged as a frontrunner in energy efficiency is the automatic feeding thermal oil boiler. This type of boiler has increasingly gained popularity across various industries due to its exceptional performance, safety features, and adaptability.

Understanding Thermal Oil Boilers

Thermal oil boilers utilize thermal oil as a heat transfer medium, providing impeccable temperature control for a wide range of heating applications. Unlike traditional steam boilers, thermal oil systems operate at lower pressures, reducing risks associated with high-pressure steam systems. This feature makes them a preferable choice for industries requiring consistent heat transfer, such as food processing, chemical production, and pharmaceuticals.

The Automatic Feeding System

One of the standout features of modern thermal oil boilers is the automatic feeding system. This technology allows for the continuous and precise feeding of fuel into the boiler, optimizing combustion efficiency. Automated systems minimize the need for manual intervention, significantly reducing labor costs and the potential for human error.

As raw materials are fed automatically, these boilers can maintain consistent operation even under varying loads. This adaptability ensures that production schedules are met with minimal downtime, enhancing overall productivity. Automatic feeders can also be integrated with advanced control systems, enabling real-time monitoring and adjustments to optimize fuel consumption and reduce emissions.

Energy Efficiency and Cost Savings

Energy efficiency is a primary concern for industries aiming to minimize operational costs while adhering to strict environmental regulations. Automatic feeding thermal oil boilers excel in this regard. Their design facilitates more efficient combustion processes, which translates to lower fuel consumption.

Moreover, by maintaining optimal performance through automatic feeding, these boilers significantly decrease the chances of heat loss. Increased thermal efficiency not only drives down fuel costs but also lessens the overall environmental impact by generating fewer greenhouse gas emissions. As industries worldwide strive to mitigate their carbon footprints, implementing energy-efficient systems like automatic feeding thermal oil boilers becomes essential.

automatic feeding thermal oil boiler product

Enhanced Safety Features

Safety is a critical factor in any industrial operation, particularly when dealing with high-temperature systems. Automatic feeding thermal oil boilers are designed with advanced safety mechanisms that minimize risks associated with overheating and pressure fluctuations. The lower operational pressure of thermal oil systems reduces the likelihood of explosions or hazardous leaks, while automated controls ensure that temperature and pressure remain within safe parameters.

Moreover, these systems often feature built-in alarms and shutdown procedures that activate during malfunction scenarios. This level of automation not only protects equipment but also safeguards workers, creating a safer working environment.

Versatility Across Industries

The versatility of automatic feeding thermal oil boilers is astonishing. They can be utilized in various applications, from maintaining optimal temperatures in oil extraction processes to facilitating thermal treatment in manufacturing operations. Industries that require precise temperature control benefit immensely from the customizable nature of these boilers.

Additionally, thermal oil systems can accommodate multiple fuel sources, including biomass, natural gas, or oil. This flexibility enables businesses to choose fuel types that align with their sustainability goals and budgetary constraints, making it an attractive option for companies invested in green technologies.

Conclusion

In conclusion, the automatic feeding thermal oil boiler stands as a testament to modern engineering’s commitment to sustainability, efficiency, and safety. The integration of automatic feeding systems streamlines operations, ensuring consistent performance while reducing labor costs and minimizing human errors.

With their impressive energy-saving capabilities and advanced safety features, these boilers are becoming invaluable assets across various industries. As the demand for energy-efficient and environmentally friendly solutions rises, automatic feeding thermal oil boilers are poised to lead the way for future innovations in thermal management and heating solutions. Embracing such advanced technologies not only enhances productivity but also paves the path for a greener, more sustainable industrial future.

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025

-

High-Efficiency Electric Steam Boiler Reliable Products & Service Leading CompaniesNewsJul.06,2025

-

High-Efficiency Biomass Pellet Boiler Reliable Steam Boiler Service & QuotesNewsJul.06,2025

-

High-Efficiency Thermal Oil Boiler for Asphalt Plant – Reliable Supplier & Factory Direct ProductNewsJul.06,2025