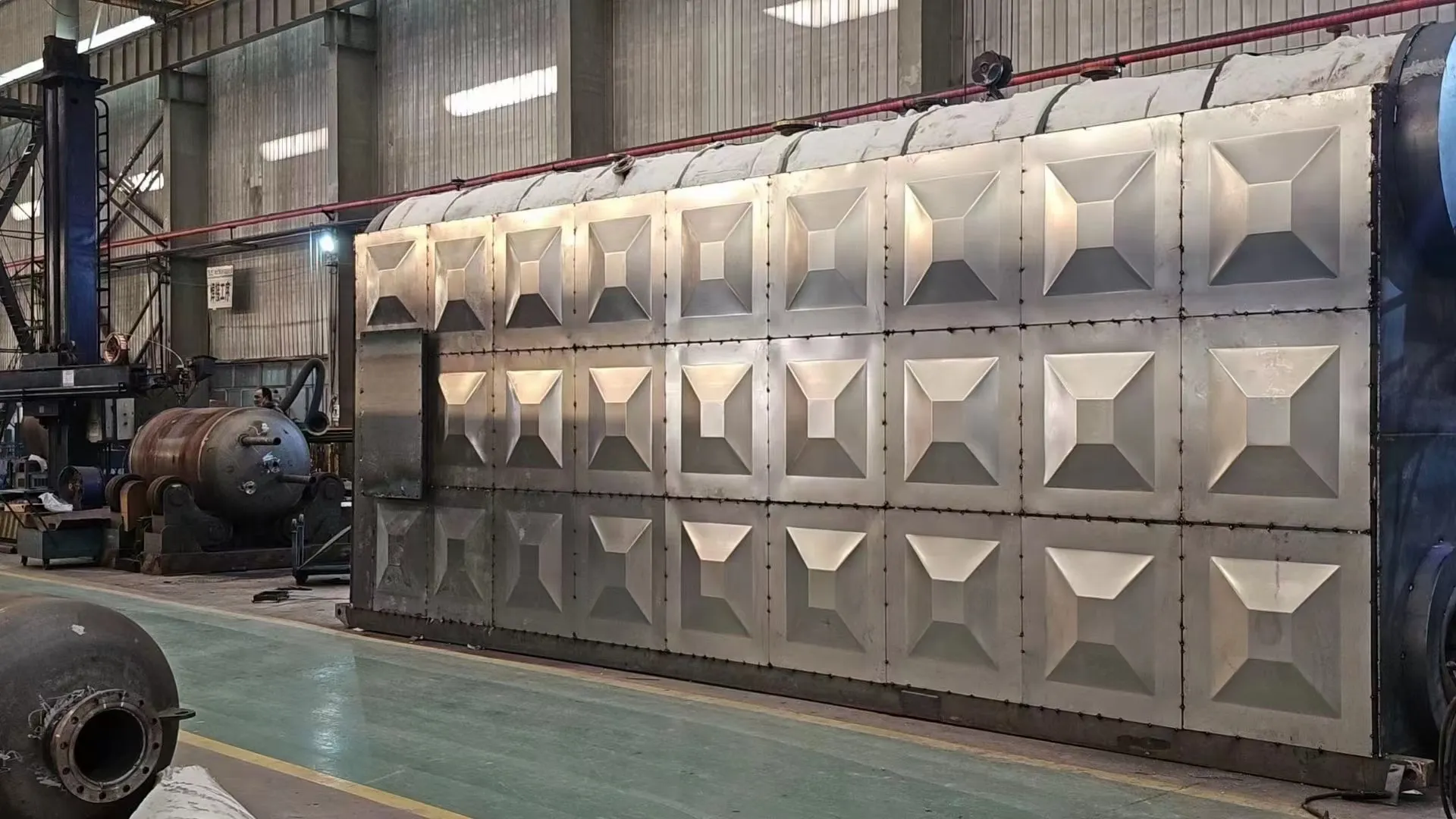

electric thermal oil heater service

Electric Thermal Oil Heater Service Ensuring Optimal Efficiency and Reliability

Electric thermal oil heaters are integral components in various industrial processes, primarily due to their efficiency in providing reliable heat transfer. Used extensively in sectors such as chemical processing, food production, and manufacturing, these systems require regular maintenance and service to ensure they operate at peak efficiency. This article explores the importance of electric thermal oil heater service and the key aspects involved in the process.

Importance of Regular Maintenance

Regular servicing of electric thermal oil heaters is crucial for several reasons. First, consistent maintenance helps identify and rectify potential issues before they develop into significant problems that could lead to costly downtime. For industries where temperature control is vital, such as in the case of thermal oil heaters used for heating liquids, maintaining consistent operating conditions is essential for product quality and safety.

Second, well-maintained heaters tend to operate more efficiently, resulting in lower energy costs. Over time, components such as pumps, heat exchangers, and controls can accumulate residue or sustain wear and tear. Regular service can help clean these components, optimize their performance, and enhance the overall thermal efficiency of the system.

Key Service Components

electric thermal oil heater service

Electric thermal oil heater service typically involves several critical tasks. Firstly, a thorough inspection of the system is conducted to check for any signs of wear, leaks, or malfunctions in components such as heating elements, pumps, and expansion tanks. Technicians will also evaluate the thermal oil quality; degraded oil can significantly impact heat transfer capabilities.

Another essential aspect of service involves testing safety mechanisms. Safety valves, temperature sensors, and pressure switches must function correctly to prevent accidents. Ensuring these components are in good condition is not only a regulatory requirement but also vital for maintaining a safe working environment.

Furthermore, technicians often recommend oil replacement and system flushing as part of the service. This practice removes impurities and ensures that the thermal oil can effectively transfer heat without degrading performance.

Conclusion

In conclusion, regular service and maintenance of electric thermal oil heaters are fundamental for ensuring their durability, efficiency, and safety. By investing in routine inspections and necessary upkeep, businesses can avoid unexpected breakdowns, optimize performance, and extend the lifespan of their heating systems. Ultimately, ensuring that electric thermal oil heaters are serviced appropriately translates to significant cost savings and enhanced productivity in various industrial applications. Hence, companies should prioritize implementing a comprehensive service schedule for their thermal oil heater systems to achieve optimal operational efficiency.

-

Industrial Steam Boiler Corporation - Reliable Industrial Boiler Manufacturer & SupplierNewsJul.08,2025

-

High-Efficiency Steam Boiler Heat Exchanger Supplier & Factory Durable Products for IndustryNewsJul.08,2025

-

Premium Electric Steam Boiler Manufacturer Reliable Company & Factory SolutionsNewsJul.08,2025

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025