OEM Reciprocating Grate Steam Boiler Solutions for Efficient Energy Generation and Management

Understanding OEM Reciprocating Grate Steam Boilers

In the realm of industrial heating solutions, steam boilers play a crucial role in various applications, from power generation to food processing. Among the different types of steam boilers, the OEM reciprocating grate steam boiler stands out due to its efficiency and versatility.

What is an OEM Reciprocating Grate Steam Boiler?

OEM, or Original Equipment Manufacturer, refers to the companies that design and manufacture boilers tailored to specific customer requirements. A reciprocating grate steam boiler employs a unique mechanical system that uses a series of moving grates to advance fuel through the combustion chamber. This design allows for more effective combustion, better fuel efficiency, and reduced emissions, making it an attractive option for eco-conscious enterprises.

Key Benefits

1. Efficiency One of the primary advantages of reciprocating grate steam boilers is their high thermal efficiency. The design allows for better air distribution and fuel mixing, leading to a more complete combustion process. This results in reduced fuel consumption and lower operational costs.

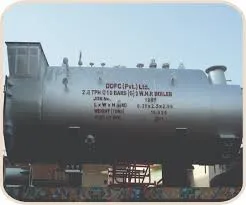

oem reciprocating grate steam boiler

2. Versatility These boilers can accommodate a wide variety of solid fuels, including biomass, coal, and other organic materials. This flexibility makes them suitable for diverse industrial applications, from manufacturing to waste-to-energy plants.

3. Emissions Reduction With stricter environmental regulations, industries must shift towards cleaner technologies. The advanced combustion technology of reciprocating grate boilers helps minimize harmful emissions, such as NOx and particulate matter, aligning with global sustainability goals.

4. Durability and Reliability OEM reciprocating grate steam boilers are built to last. They are constructed from high-quality materials that ensure resilience against the demanding conditions of industrial operations. The robust design and efficient operation contribute to prolonged service life and reduced maintenance needs.

Conclusion

In conclusion, OEM reciprocating grate steam boilers represent a significant advancement in steam generation technology. Their efficiency, adaptability to various fuels, and reduced environmental impact make them an ideal choice for industries looking to optimize their operations while adhering to environmental standards. As manufacturers continue to innovate and refine these systems, the future of steam boiler technology looks promising, paving the way for more sustainable and efficient industrial practices. Whether for energy production or process heating, investing in an OEM reciprocating grate steam boiler can provide substantial benefits for businesses across numerous sectors.

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025