Steam Boiler and Heat Exchanger Pricing Guide for Effective Budget Planning

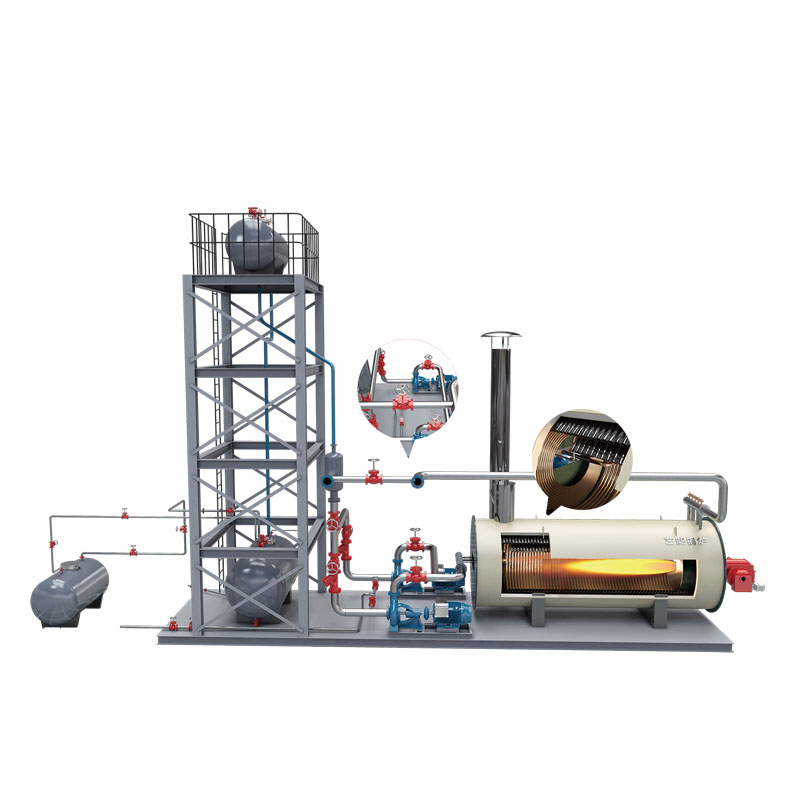

When it comes to industrial applications, steam boiler heat exchangers play a crucial role in thermal efficiency and energy conservation. These components are essential in various sectors, including power generation, oil refining, chemical production, and food processing. Given their importance, understanding the pricing of steam boiler heat exchangers is vital for businesses looking to optimize their operations and maintain budgetary constraints.

.

Material choice is another critical factor in determining the price. Heat exchangers can be made from various materials, including stainless steel, carbon steel, and specialized alloys. While stainless steel offers excellent corrosion resistance and durability, it comes at a higher price. On the other hand, carbon steel, although less expensive, may not be suitable for high-pressure or corrosive environments.

steam boiler heat exchanger pricelist

Additionally, the size and capacity of the heat exchanger directly correlate with its price. Larger units that can handle higher capacities will naturally be more expensive due to increased material usage and complexity in manufacturing. Thus, businesses must assess their thermal needs accurately to choose a heat exchanger that fits both their operational requirements and budget.

Another key aspect influencing pricing is the manufacturer’s reputation and after-sales support. Renowned manufacturers often charge a premium for their heat exchangers, reflecting the quality, reliability, and warranty services they offer. It is advisable to consider both the initial investment and the long-term benefits of superior products when budgeting for a steam boiler heat exchanger.

In conclusion, while creating a pricing strategy for steam boiler heat exchangers, businesses need to consider multiple factors, including design, material, size, and manufacturer reputation. By understanding these elements, companies can make informed investments that enhance operational efficiency and provide significant cost savings over time. Always consult with industry experts and suppliers to ensure you obtain the best value for your specific application and operational demands.

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025

-

High-Efficiency Electric Steam Boiler Reliable Products & Service Leading CompaniesNewsJul.06,2025

-

High-Efficiency Biomass Pellet Boiler Reliable Steam Boiler Service & QuotesNewsJul.06,2025

-

High-Efficiency Thermal Oil Boiler for Asphalt Plant – Reliable Supplier & Factory Direct ProductNewsJul.06,2025