ינו . 24, 2025 00:51

Back to list

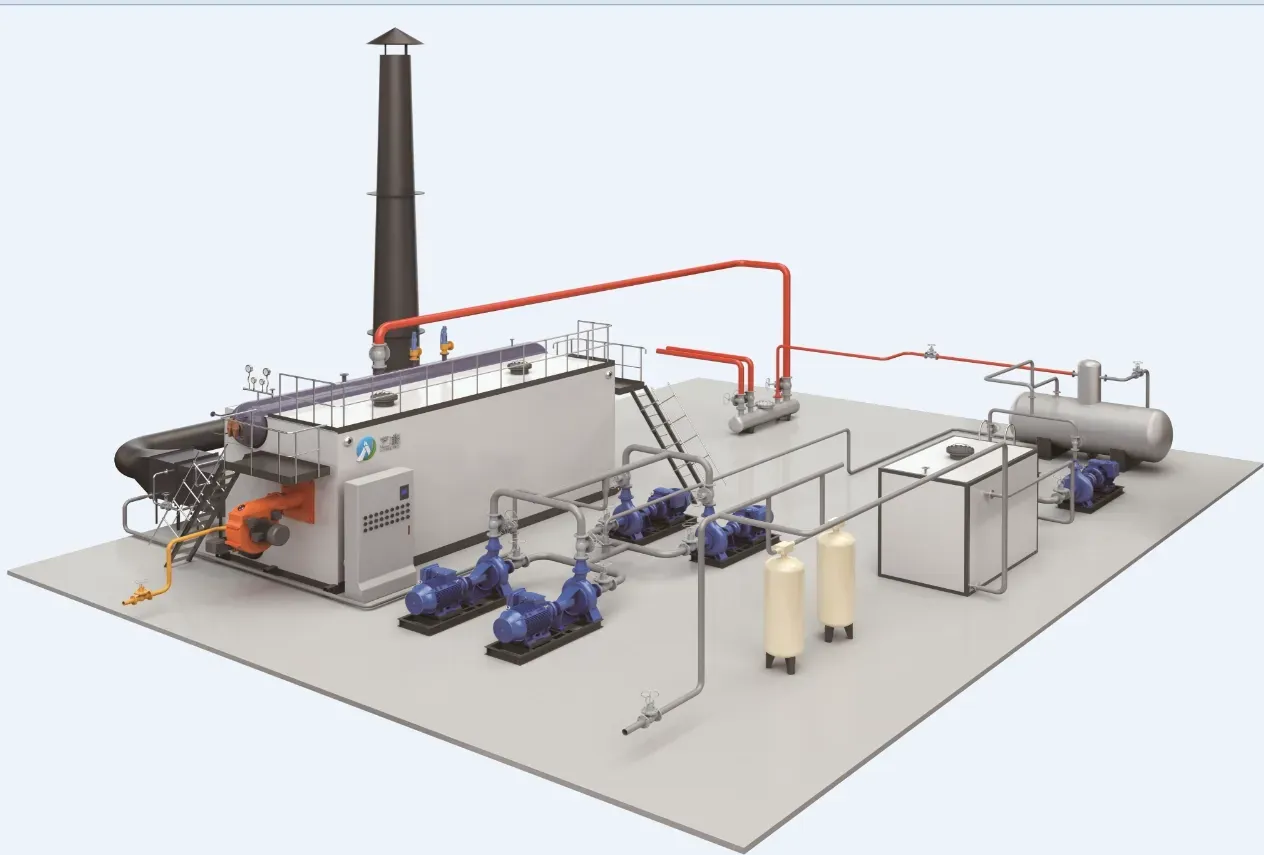

waste heat recovery boiler power plant

Amid the pressing need for sustainable and efficient energy solutions, the waste heat recovery boiler power plant stands out as a pivotal innovation in the energy sector. This technology not only optimizes energy usage but also significantly reduces environmental impact, fostering a win-win situation for both industries and the planet.

Trustworthiness is crucial for industries considering investment in waste heat recovery systems. Partnering with reputable companies that have a proven track record of successful implementations is vital. Potential stakeholders should scrutinize case studies, client testimonials, and the company's history in these technologies. Furthermore, transparent communication regarding expected outcomes, costs, and timelines fosters a trusting relationship and assures stakeholders of the project's viability. One compelling case of successful waste heat recovery implementation is in the cement industry. Cement production is notoriously energy-intensive, but by incorporating waste heat recovery systems, one plant managed to generate approximately 30% of its electricity demand through recovered heat alone. This not only reduced operational costs but also decreased the plant's carbon footprint, showcasing a model of sustainable industrial practice. Maintenance and operational training are also pivotal elements in ensuring the long-term success of a waste heat recovery system. Investing in regular system audits and staff training programs can prevent efficiency degradation and unexpected downtimes. Many companies provide comprehensive training modules for on-site engineers and operators to equip them with the necessary skills to handle potential challenges. In conclusion, waste heat recovery boiler power plants epitomize an ingenious solution to two concomitant challenges energy inefficiency and environmental degradation. Through meticulous design and execution, these systems offer tangible benefits to industries in terms of cost savings, compliance with environmental regulations, and enhanced sustainability credentials. Companies that recognize the value and potential of waste heat recovery are not only positioning themselves as leaders in energy innovation but are also actively contributing to a more sustainable future. As we advance, the widespread adoption of such technologies could redefine industrial practices and pave the way for a more energy-conscious world.

Trustworthiness is crucial for industries considering investment in waste heat recovery systems. Partnering with reputable companies that have a proven track record of successful implementations is vital. Potential stakeholders should scrutinize case studies, client testimonials, and the company's history in these technologies. Furthermore, transparent communication regarding expected outcomes, costs, and timelines fosters a trusting relationship and assures stakeholders of the project's viability. One compelling case of successful waste heat recovery implementation is in the cement industry. Cement production is notoriously energy-intensive, but by incorporating waste heat recovery systems, one plant managed to generate approximately 30% of its electricity demand through recovered heat alone. This not only reduced operational costs but also decreased the plant's carbon footprint, showcasing a model of sustainable industrial practice. Maintenance and operational training are also pivotal elements in ensuring the long-term success of a waste heat recovery system. Investing in regular system audits and staff training programs can prevent efficiency degradation and unexpected downtimes. Many companies provide comprehensive training modules for on-site engineers and operators to equip them with the necessary skills to handle potential challenges. In conclusion, waste heat recovery boiler power plants epitomize an ingenious solution to two concomitant challenges energy inefficiency and environmental degradation. Through meticulous design and execution, these systems offer tangible benefits to industries in terms of cost savings, compliance with environmental regulations, and enhanced sustainability credentials. Companies that recognize the value and potential of waste heat recovery are not only positioning themselves as leaders in energy innovation but are also actively contributing to a more sustainable future. As we advance, the widespread adoption of such technologies could redefine industrial practices and pave the way for a more energy-conscious world.

Latest news

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025

-

High-Efficiency Electric Steam Boiler Reliable Products & Service Leading CompaniesNewsJul.06,2025

-

High-Efficiency Biomass Pellet Boiler Reliable Steam Boiler Service & QuotesNewsJul.06,2025

-

High-Efficiency Thermal Oil Boiler for Asphalt Plant – Reliable Supplier & Factory Direct ProductNewsJul.06,2025