Purchasing Steam Boilers for the Rubber Manufacturing Sector

The Importance of Steam Boilers in the Rubber Industry

The rubber industry is a vital sector contributing to a wide range of products, from tires to medical devices. One critical component of the manufacturing process in this industry is the steam boiler. Steam boilers provide the necessary heat and pressure to transform raw rubber into usable products, making them integral to production lines. In this article, we will explore the significance of steam boilers in the rubber industry, the factors to consider when purchasing one, and the advantages of investing in high-quality equipment.

Understanding the Role of Steam Boilers

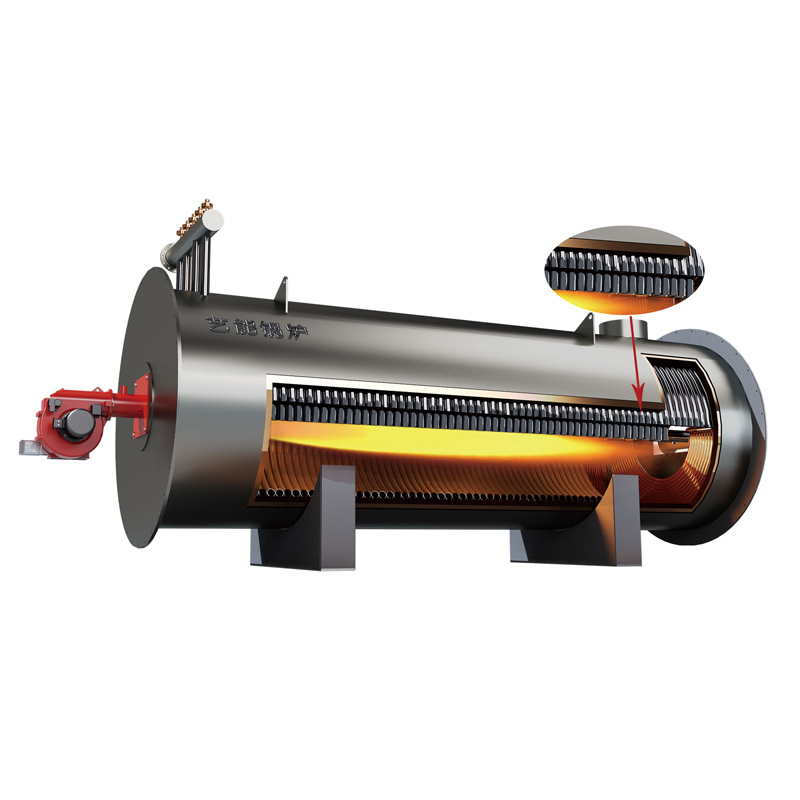

In rubber manufacturing, steam boilers are used to generate steam that is crucial for several processes, including curing, molding, and vulcanization. Vulkanization is a chemical process that transforms raw rubber into durable and elastic materials through the application of heat and pressure. Without a reliable steam boiler, the efficiency and quality of the rubber products could be compromised, leading to increased production costs and potential defects.

Furthermore, steam boilers help maintain consistent temperatures, which is essential for achieving uniform results in rubber production. Variations in temperature can lead to inconsistencies in the final product, resulting in additional waste and rework. Therefore, having a dependable steam boiler is not just a matter of convenience but a necessity for maintaining product quality and operational efficiency.

Factors to Consider When Buying a Steam Boiler

When looking to purchase a steam boiler for the rubber industry, several factors must be considered

1. Boiler Capacity The capacity of the boiler should align with the production demands. Assessing the volume of steam required for various processes will help determine the appropriate boiler size. Oversized boilers can lead to inefficiencies, while undersized boilers may not meet production needs.

2. Fuel Type Different types of fuel can be used in steam boilers, including natural gas, oil, and electricity. The choice of fuel will depend on factors such as availability, cost, and environmental considerations. It is crucial to evaluate which fuel option will offer the best performance for the rubber manufacturing process.

3. Efficiency Ratings Energy efficiency is an essential consideration when selecting a steam boiler. An efficient boiler can lead to significant cost savings over time by reducing energy consumption. Look for boilers that have high efficiency ratings and consider options that come with energy-saving features.

buy steam boiler for rubber industry

4. Durability and Maintenance Investing in a robust and durable steam boiler can lead to lower maintenance costs and longer life expectancy. Look for models that are built with high-quality materials and offer warranties. Regular maintenance is also vital, so consider the ease of access for servicing when making your choice.

5. Compliance with Regulations Ensure that the steam boiler you choose meets all local and national regulations regarding emissions and safety standards. Non-compliance can lead to costly fines and legal issues, making it crucial to verify that the equipment adheres to the necessary guidelines.

Advantages of Investing in High-Quality Steam Boilers

Purchasing a high-quality steam boiler brings several advantages to the rubber manufacturing process

- Improved Product Quality A reliable steam boiler ensures consistent temperature and pressure, which leads to enhanced product quality. This reliability helps in minimizing defects and reducing wastage.

- Increased Efficiency High-quality boilers are designed to operate more efficiently, resulting in lower energy costs and faster production times. This efficiency can boost the overall productivity of the manufacturing operation.

- Reduced Downtime Quality steam boilers are less prone to breakdowns, meaning that manufacturing processes can continue with minimal interruptions. This reduces downtime, which is crucial for meeting production deadlines.

- Eco-Friendly Options Many modern steam boilers are built with environmental concerns in mind, offering features that reduce emissions and overall environmental impact. Investing in such technology can enhance a company's reputation as a responsible and sustainable manufacturer.

Conclusion

In conclusion, steam boilers play a pivotal role in the rubber industry, enabling manufacturers to produce high-quality products efficiently and reliably. When purchasing a steam boiler, it is essential to consider factors like capacity, fuel type, efficiency, durability, and compliance with regulations. By investing in a high-quality steam boiler, rubber manufacturers can improve their production processes, reduce costs, and enhance product quality, ultimately leading to greater success in an increasingly competitive market.

-

Industrial Steam Boiler Corporation - Reliable Industrial Boiler Manufacturer & SupplierNewsJul.08,2025

-

High-Efficiency Steam Boiler Heat Exchanger Supplier & Factory Durable Products for IndustryNewsJul.08,2025

-

Premium Electric Steam Boiler Manufacturer Reliable Company & Factory SolutionsNewsJul.08,2025

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025