Efficient Thermal Oil Heaters for Optimal Heating Solutions in Various Applications

The Evolution and Benefits of Jual Thermal Oil Heaters

In today's industrial landscape, efficient heating solutions play a crucial role in enhancing productivity while minimizing energy costs. Among these solutions, thermal oil heaters have emerged as a preferred choice for a variety of industries. From food processing to chemical manufacturing, these heaters provide a reliable and efficient means of heat transfer. In this article, we will delve into the concept of jual thermal oil heaters, exploring their functionality, advantages, and applications.

Understanding Thermal Oil Heaters

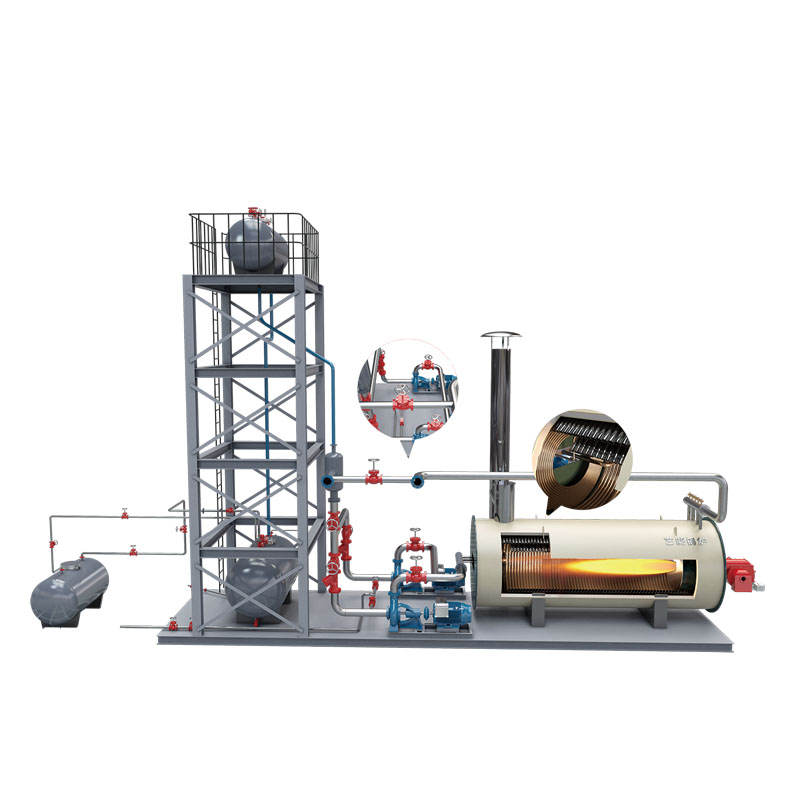

Thermal oil heaters operate on a simple yet effective principle they utilize thermal oil as a heat transfer medium to transfer heat from one point to another. In contrast to conventional water-based boilers, thermal oil heaters offer the flexibility to operate at higher temperatures without the risk of pressure buildup. The design of these heaters allows them to heat the thermal oil to a temperature often exceeding 300°C (572°F), making them ideal for processes requiring high thermal efficiency.

The core components of a thermal oil heater system include the heater itself, circulating pumps, thermal oil, and control systems. The thermal oil circulates through the system, transferring heat to the intended application, whether it be for indirect heating of materials or for specific processes within manufacturing.

Benefits of Thermal Oil Heaters

1. High Efficiency and Energy Savings

One of the most significant benefits of using thermal oil heaters is their high efficiency. They achieve superior heat transfer, reducing energy consumption compared to traditional steam heating systems. This efficiency translates directly into lower operational costs, making thermal oil heaters an economical choice for long-term use.

2. Ability to Achieve High Temperatures

Thermal oil heaters can deliver heat at high temperatures with absolute safety and stability. This capability is essential in various applications, including those in the chemical, textile, and food industries, where processes require specific temperature profiles.

3. Flexibility in Design and Application

These heaters come in various sizes and configurations, enabling customization for specific industrial requirements. Whether it is a simple batch process or a complex continuous system, thermal oil heaters can be tailored to fit distinct heating needs.

jual thermal oil heater

With energy-efficient operation, thermal oil heaters contribute to lower greenhouse gas emissions. Moreover, many models are designed to comply with stringent environmental regulations, further minimizing their ecological impact.

5. Safety and Reliability

Unlike water-based systems, thermal oil systems operate at lower pressures, which enhances safety by reducing the risk of accidents related to pressure build-up. The stability of thermal oil ensures a consistent performance, contributing to reliability in industrial processes.

Applications of Thermal Oil Heaters

The versatility of thermal oil heaters makes them suitable for a wide range of applications. Some of the key industries utilizing these systems include

- Chemical Manufacturing Many chemical processes require precise temperature control, which thermal oil heaters provide, ensuring optimal production efficiency.

- Food Processing In the food industry, these heaters are used for cooking, drying, and maintaining product quality without altering ingredients.

- Textile Production The textile industry relies on thermal oil heaters for dyeing processes, where consistent temperature control is vital.

- Oil and Gas Thermal oil heaters serve as crucial heating sources for various components in oil and gas extraction and processing.

- Pharmaceuticals In the pharmaceutical sector, maintaining specific temperatures is vital for product stabilization and efficacy.

Conclusion

In conclusion, jual thermal oil heaters represent an essential component of modern industrial heating systems. Their ability to provide high-efficiency heating, achieve elevated temperatures safely, and accommodate various applications makes them an indispensable asset in many sectors. With growing emphasis on energy efficiency and environmental sustainability, the demand for thermal oil heaters is likely to continue increasing, driving innovations in their technology and applications. As industries strive to enhance performance and reduce costs, investing in thermal oil heating solutions seems to be a prudent choice for future growth and sustainability.

-

Industrial Steam Boiler Corporation - Reliable Industrial Boiler Manufacturer & SupplierNewsJul.08,2025

-

High-Efficiency Steam Boiler Heat Exchanger Supplier & Factory Durable Products for IndustryNewsJul.08,2025

-

Premium Electric Steam Boiler Manufacturer Reliable Company & Factory SolutionsNewsJul.08,2025

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025