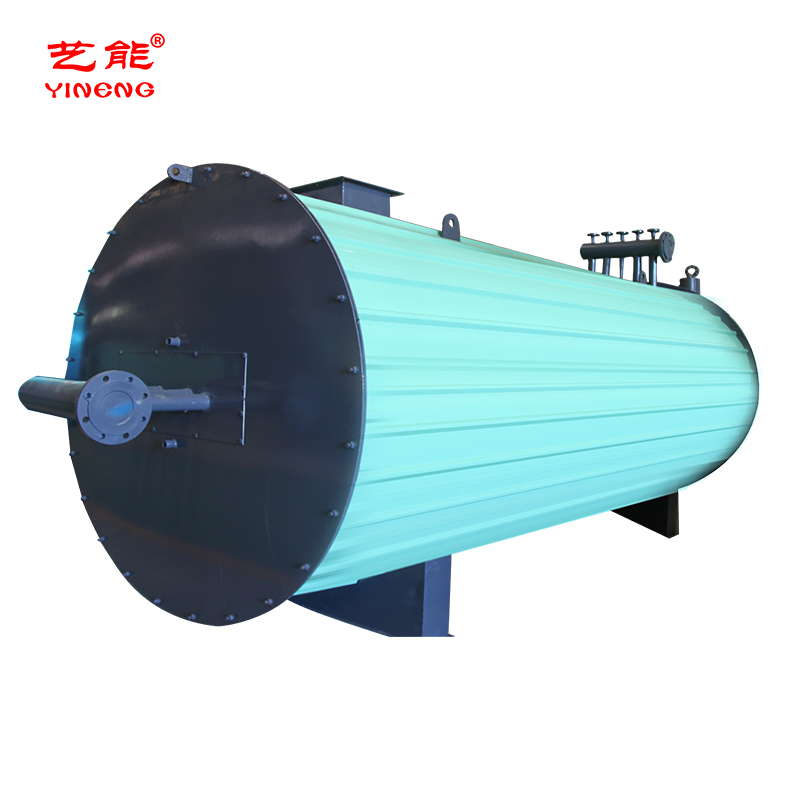

boiler for leather factory supplier

When it comes to the leather manufacturing industry, efficiency, quality, and sustainability are essential components that determine a factory's success. One pivotal element in this process is the boiler system, which plays a crucial role in providing the necessary steam and heat for various production stages, including tanning, drying, and finishing leather products. Selecting the right boiler for a leather factory is paramount, and working with a reliable supplier can significantly impact overall production quality and energy consumption.

.

Another essential consideration is the type of fuel used by the boiler. Leather factories often seek options that allow for both efficiency and environmental sustainability. Modern boilers can use various fuels, including natural gas, biomass, or even waste heat recovery systems, which can help reduce operating costs and lessen the environmental footprint of the factory. A knowledgeable supplier will provide insights into the best fuel options available for the specific needs of a leather factory, bearing in mind both operational capabilities and sustainability goals.

boiler for leather factory supplier

Additionally, the efficiency of the boiler system is critical. High-efficiency boilers minimize energy waste, reducing operational costs and improving the factory's bottom line. Suppliers can offer advanced technology solutions that are designed to enhance efficiency, including condensing boilers and those with integrated economizers. These innovations not only contribute to lower energy bills but also play a role in meeting industry standards for energy usage and emissions.

Moreover, maintenance and after-sales support are vital when choosing a boiler supplier. Regular maintenance ensures that the boiler operates at peak performance and prolongs its lifespan. A reliable supplier should offer comprehensive service contracts that include routine maintenance, emergency repairs, and access to spare parts. This level of support is essential to prevent downtime in production, which can be costly for a leather factory.

In conclusion, the selection of a boiler for a leather factory is a critical decision influenced by several factors, including capacity, fuel type, efficiency, and maintenance support. Partnering with a reputable supplier can significantly enhance a factory's operational performance while ensuring sustainable practices are upheld. As the leather industry continues to evolve, investing in the right boiler system will undoubtedly play a pivotal role in achieving both productivity and sustainability goals.

-

Thermal Oil Boiler for Plywood Industry Efficient & Reliable SupplierNewsApr.29,2025

-

High-Efficiency Condensing Hot Water Boilers Supplier & FactoryNewsApr.29,2025

-

Vertical Thermal Oil Boilers High-Efficiency Industrial Heating SolutionsNewsApr.28,2025

-

High-Efficiency Gas Hot Water Boiler Energy-Saving & ReliableNewsApr.28,2025

-

Burnham Independence BTU Steam Boiler NG High-Efficiency SupplierNewsApr.28,2025

-

Steam Boiler Factory High-Efficiency & Custom Industrial SolutionsNewsApr.28,2025