China Boiler for MDF Production Line - Efficient and Reliable Solutions

The Role of China Boilers in MDF Production Lines

Medium-density fiberboard (MDF) has become one of the most popular materials in the manufacturing of furniture and construction products. Its production process relies heavily on various machines, with boilers playing a pivotal role in ensuring efficiency and quality. China has emerged as a leading supplier of boilers specifically designed for MDF production lines, making significant contributions to this industry's growth and development.

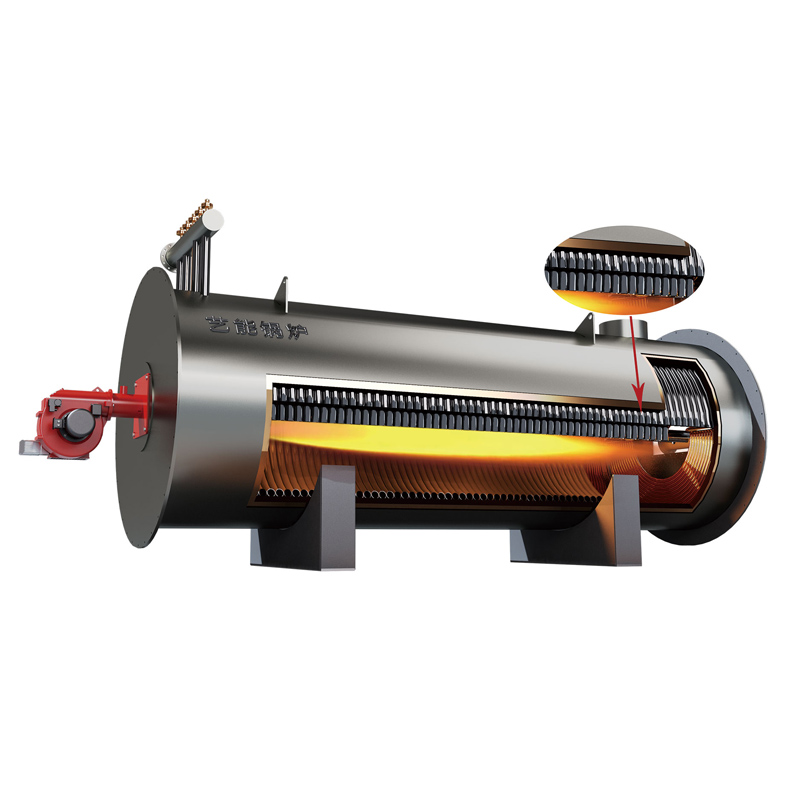

MDF is produced by breaking down wood fibers into smaller particles, which are then combined with adhesives and heated under pressure to form durable boards. This process requires precise temperature and pressure control, which is where the role of boilers becomes critical. The quality of the boiler directly affects the energy efficiency, steam quality, and overall productivity of the MDF production line.

The Role of China Boilers in MDF Production Lines

One of the significant advantages of using China boilers in MDF production is their versatility. Many of these boilers can run on various fuel sources, including natural gas, biomass, and coal. This flexibility is particularly beneficial for MDF producers looking to manage energy costs while adhering to environmental regulations. With China's strong emphasis on renewable energy, many boiler models are now designed to operate efficiently on biomass fuels, such as sawdust and wood chips—byproducts of the MDF production process itself.

china boiler for mdf production line

Furthermore, the competitive pricing of Chinese boilers makes them an attractive choice for MDF manufacturers worldwide. By offering high-quality equipment at lower costs, Chinese suppliers have enabled manufacturers in developing countries to invest in modern production lines, ultimately enhancing their competitiveness in the global market. This trend has spurred economic growth and job creation across various regions.

Additionally, the after-sales support provided by Chinese boiler manufacturers is a critical aspect of their appeal. Many companies offer comprehensive service packages, including installation support, maintenance services, and spare parts availability. This commitment to customer service ensures that MDF producers can rely on their equipment for consistent performance and quick resolutions in case of any operational hiccups.

However, despite the numerous advantages, MDF manufacturers must be mindful of the environmental impact associated with production. China's commitment to reducing carbon emissions and improving air quality has led to stricter regulations on industrial emissions. As a result, manufacturers must ensure that their boiler systems meet these requirements, promoting cleaner production practices.

In conclusion, China’s boilers for MDF production lines represent a blend of technological innovation, cost-effectiveness, and environmental awareness. As the global demand for MDF continues to rise, the role of these boilers becomes increasingly significant. For MDF producers, investing in high-quality, efficient, and environmentally friendly boilers from China not only supports their operational goals but also contributes to sustainable industrial practices. As the industry evolves, the partnership between MDF manufacturers and Chinese boiler suppliers will be crucial for creating a more efficient and sustainable future in wood-based panel production.

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025