Jan . 17, 2025 02:14

Back to list

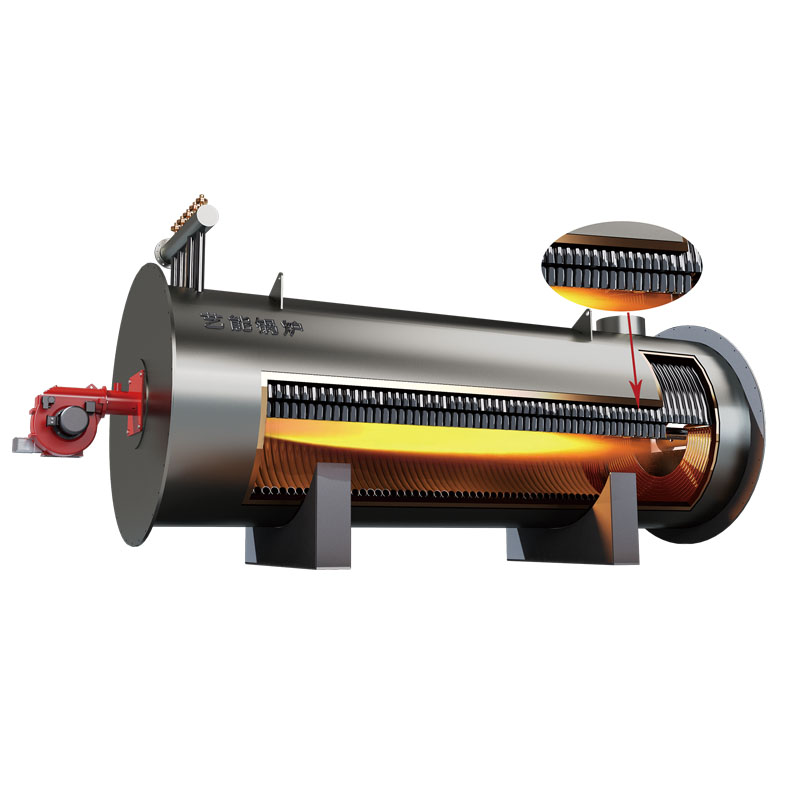

thermal oil boiler for eps

Selecting a thermal oil boiler for your EPS (Expanded Polystyrene) production facility involves careful consideration of various factors that ensure efficiency, safety, and cost-effectiveness. As experts in the field of industrial heating solutions, we leverage our extensive experience to help businesses make informed decisions about their thermal oil systems.

It is also vital to ensure the thermal oil boiler is equipped with state-of-the-art control systems. Advanced digital controllers enable real-time monitoring and optimization of the heating process. This enhances process precision and provides diagnostic tools to preemptively address potential issues, thereby minimizing downtime and extending the lifespan of the equipment. Expert consultation is recommended when integrating a thermal oil boiler into an EPS production line. Professional engineers can offer tailored advice on installation, system configuration, and optimal operational strategies. This expertise ensures that the heating system is aligned with your facility's specific needs, complies with safety standards, and integrates smoothly with existing infrastructure. Beyond the equipment itself, the reliability of the manufacturer and supplier plays a critical role in long-term success. Opting for established companies with a history of innovation and customer satisfaction in industrial heating solutions enhances trustworthiness. Access to comprehensive after-sales support, including maintenance services and readily available spare parts, is crucial for ongoing operations. In conclusion, the choice of a thermal oil boiler for EPS production is a multifaceted decision that requires attention to safety, efficiency, and long-term operational goals. By prioritizing quality equipment, advanced control systems, and experienced partners, businesses can enhance their production capabilities while ensuring reliable and sustainable processes. Our expertise and commitment to excellence provide a foundation upon which your facility can thrive, delivering high-quality EPS products to meet market demands.

It is also vital to ensure the thermal oil boiler is equipped with state-of-the-art control systems. Advanced digital controllers enable real-time monitoring and optimization of the heating process. This enhances process precision and provides diagnostic tools to preemptively address potential issues, thereby minimizing downtime and extending the lifespan of the equipment. Expert consultation is recommended when integrating a thermal oil boiler into an EPS production line. Professional engineers can offer tailored advice on installation, system configuration, and optimal operational strategies. This expertise ensures that the heating system is aligned with your facility's specific needs, complies with safety standards, and integrates smoothly with existing infrastructure. Beyond the equipment itself, the reliability of the manufacturer and supplier plays a critical role in long-term success. Opting for established companies with a history of innovation and customer satisfaction in industrial heating solutions enhances trustworthiness. Access to comprehensive after-sales support, including maintenance services and readily available spare parts, is crucial for ongoing operations. In conclusion, the choice of a thermal oil boiler for EPS production is a multifaceted decision that requires attention to safety, efficiency, and long-term operational goals. By prioritizing quality equipment, advanced control systems, and experienced partners, businesses can enhance their production capabilities while ensuring reliable and sustainable processes. Our expertise and commitment to excellence provide a foundation upon which your facility can thrive, delivering high-quality EPS products to meet market demands.

Latest news

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025