Innovative Solutions for Utilizing Waste Heat in Steam Boiler Systems and Enhancing Energy Efficiency

Waste Heat Steam Boiler Products Harnessing Energy Efficiently

In the quest for sustainable energy solutions, one of the most promising technologies is the waste heat steam boiler. These innovative products play a crucial role in enhancing energy efficiency by utilizing residual heat from industrial processes, thereby reducing energy consumption and greenhouse gas emissions.

What is a Waste Heat Steam Boiler?

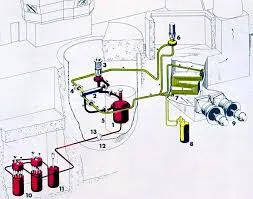

A waste heat steam boiler is a specialized device designed to capture and convert waste heat generated by various industrial processes into steam. This steam can be used to drive turbines for electricity generation, provide thermal energy for heating applications, or serve other processes within a facility. Waste heat recovery systems are particularly relevant in industries such as petrochemicals, metal production, and cement manufacturing, where significant amounts of heat are produced as byproducts.

The Importance of Energy Efficiency

The increasing global focus on sustainability and energy efficiency has heightened interest in waste heat recovery technologies. Traditional energy generation methods often involve the combustion of fossil fuels, resulting in high levels of carbon emissions. By capturing and reusing waste heat, facilities can substantially decrease their fuel consumption and emissions. For instance, industries that adopt waste heat steam boilers can achieve thermal efficiencies exceeding 90%, transforming what would otherwise be lost energy into productive use.

Applications of Waste Heat Steam Boilers

Waste heat steam boilers can be applied in various scenarios

1. Power Generation By integrating waste heat boilers with steam turbines, industries can generate additional electricity without the need for extra fuel. This is particularly beneficial in energy-intensive sectors like steel and glass manufacturing.

3. District Heating Waste heat recovery can also contribute to district heating systems, supplying residential and commercial buildings with thermal energy from industrial waste heat.

waste heat steam boiler products

4. Environmental Compliance Utilizing waste heat technologies helps industries comply with stringent environmental regulations by minimizing waste and emissions.

Benefits of Waste Heat Steam Boiler Products

The advantages of waste heat steam boiler products extend beyond environmental benefits

- Cost Savings By reducing the dependency on purchased fuel and increasing efficiency, companies can lower operational costs significantly.

- Return on Investment (ROI) Many organizations experience rapid ROI from waste heat recovery systems due to immediate energy savings and reduced operational expenses.

- Enhanced Productivity With reliable steam generation from waste heat, industries can maintain continuous processes and enhance overall productivity.

- Improved Corporate Image Implementing sustainability initiatives, such as waste heat recovery, can improve a company’s reputation, attract eco-conscious consumers, and meet stakeholder expectations.

Challenges and Considerations

Despite the numerous advantages, implementing waste heat steam boiler systems can come with challenges. Technical complexities, high initial capital costs, and the need for integrated designs tailored to specific industrial processes can hinder adoption. However, with the right expertise and investment, these hurdles can be overcome, paving the way for a more sustainable industrial landscape.

Conclusion

Waste heat steam boiler products represent a promising technology in the transition towards energy-efficient and sustainable industrial practices. By effectively harnessing residual heat, these systems not only contribute to cost savings and improved productivity but also play a vital role in reducing environmental impact. As industries continue to seek innovative solutions to meet energy demands while adhering to sustainability goals, the importance of waste heat recovery will only continue to grow.

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.06,2025

-

Top Electric Steam Boiler Manufacturers | AI EfficiencyNewsAug.04,2025

-

Efficient Thermal Oil Boilers with AI Optimization | Superior PerformanceNewsAug.03,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025