Low Water Cut-Off Service for Steam Boilers to Ensure Safe Operation

Understanding Low Water Cut Off in Steam Boiler Service

Steam boilers are critical components in various industries, providing heating and powering systems that are essential for operations. However, like any mechanical device, they require regular maintenance and monitoring to ensure safety and efficiency. One of the most crucial safety features in a steam boiler is the low water cut off (LWCO). This article will delve into the importance of LWCO, its functionality, maintenance, and role in enhancing boiler safety.

What is a Low Water Cut Off?

Low water cut off devices are safety mechanisms designed to prevent steam boilers from operating when the water level drops below a certain point. The primary function of an LWCO is to detect the water level in the boiler and automatically shut off the burner if the water level falls too low. This is vital because operating a steam boiler with insufficient water can lead to severe damage, including overheating, pressure build-up, and even boiler failure or explosion.

How Does it Work?

The low water cut off system operates through various technologies, including mechanical floats, probes, and electronic sensors. The most common type involves a float mechanism. As water levels fluctuate, the float rises and falls accordingly. When the water level drops to a specified threshold, the float descends, triggering the switch that disconnects the fuel supply to the burner. This action effectively prevents the boiler from running dry and damaging the system.

In more advanced installations, electronic sensors may be utilized. These sensors can provide more precise water level readings and often include diagnostic capabilities. They can alert operators to potential issues, such as a malfunctioning feedwater system or components that require maintenance.

Importance of Low Water Cut Off in Boiler Safety

The importance of low water cut off devices cannot be overstated. First and foremost, they act as a safeguard against water depletion, which is a leading cause of boiler failure. Without adequate water, the boiler's metal components can warp or crack due to excessive temperatures, resulting in costly repairs and extended downtime.

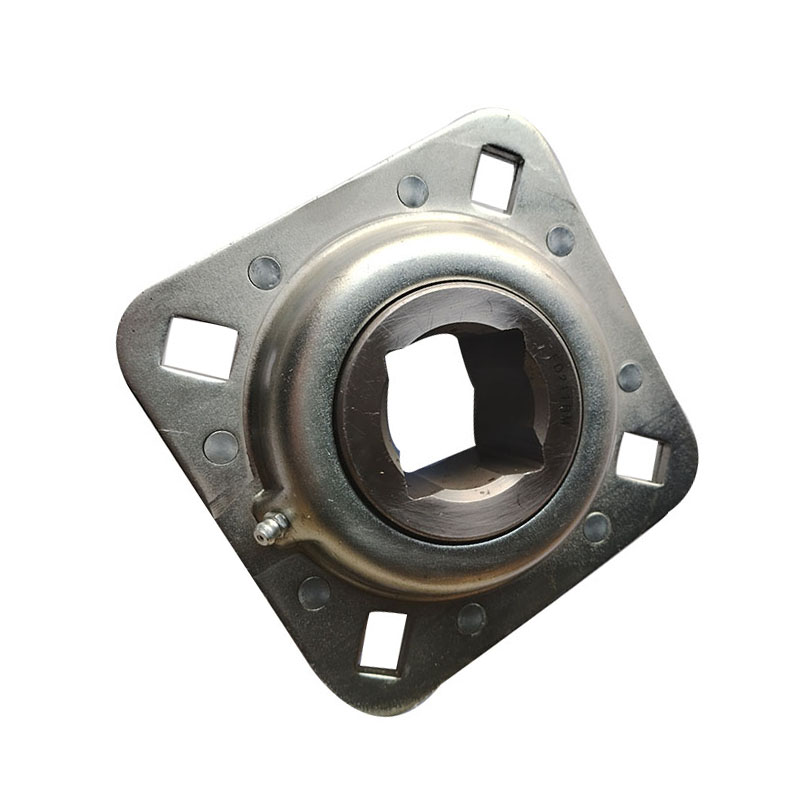

low water cut off steam boiler service

Additionally, an efficient low water cut off system contributes to overall operational efficiency. By ensuring that water levels remain within safe parameters, LWCO devices help maintain optimal steam production levels and reduce fuel consumption. This not only cuts operational costs but also minimizes environmental impact.

Routine Maintenance

Regular maintenance of low water cut off devices is critical. Operators should inspect these systems consistently to ensure they are functioning correctly. Maintenance tasks typically include

1. Visual inspections Checking for corrosion, leaks, and proper alignment of the float mechanism. 2. Functional testing Regularly testing the low water cut off to verify its performance and reliability. This can involve lowering the water level to see if the shut-off activates as intended.

3. Cleaning Removing any buildup or debris that might impede the float or sensor. This is essential for ensuring accurate readings.

4. Calibration and Adjustment Ensuring that the device is properly calibrated to respond to specific water levels indicated in the manufacturer’s guidelines.

5. Recordkeeping Documenting maintenance activities allows for better tracking of system performance and aids in identifying recurring issues.

Conclusion

In summary, the low water cut off is an essential component of steam boiler operation and safety. By effectively monitoring water levels, these devices prevent significant damage and ensure the efficient functioning of the system. Regular maintenance and testing are paramount to guarantee that the LWCO operates correctly, allowing steam boilers to perform reliably and safely. Understanding the functionality and importance of these devices ultimately helps prevent disasters, improve efficiency, and extend the lifespan of steam boiler systems. Investing in proper servicing and attention to the low water cut off mechanism is a small price to pay for the immense safety and operational benefits it provides.

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025