Қаң . 17, 2025 00:50

Back to list

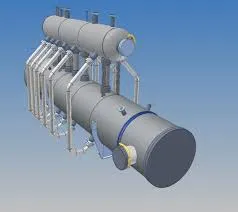

oil boiler for plywood factory

Optimizing the energy efficiency and operational costs of a plywood factory is crucial for maintaining competitiveness in the industry. One of the essential components in such operations is an oil boiler, which significantly influences the production process, energy consumption, and overall sustainability of the manufacturing activities. Understanding the integration of an oil boiler into a plywood factory can provide valuable insights into enhancing production effectiveness.

Trustworthiness is a crucial element when considering the selection and implementation of an oil boiler. Engaging with manufacturers and service providers who have a proven track record of reliability and customer satisfaction is vital. They can offer warranties, regular maintenance schedules, and 24/7 customer support, giving factories peace of mind and assurance that their production processes remain seamless. Cutting-edge oil boiler technologies often incorporate advanced digital controls and automation systems. These systems allow for precise monitoring and management of heat production, contributing to enhanced safety and efficiency within the factory. Automation minimizes human error and optimizes fuel usage, further establishing the oil boiler as a trusted, reliable component of the plywood production infrastructure. The shift towards sustainable manufacturing practices has also influenced the evolution of oil boilers. Today's modern oil boilers are designed with enhanced emission control capabilities, significantly reducing the release of harmful pollutants and aligning with global environmental standards. This progress in boiler technology not only assists factories in reducing their carbon footprint but also opens doors to new markets that prioritize green and sustainable production. In conclusion, the role of an oil boiler in a plywood factory extends beyond merely supplying heat. It is a critical component that influences the entire production efficiency, energy consumption, and environmental impact of the operations. By leveraging advanced boiler technologies, tapping into industry expertise, and prioritizing trustworthy partnerships, plywood manufacturers can achieve a sustainable and cost-effective production environment that meets both current operational demands and future growth objectives.

Trustworthiness is a crucial element when considering the selection and implementation of an oil boiler. Engaging with manufacturers and service providers who have a proven track record of reliability and customer satisfaction is vital. They can offer warranties, regular maintenance schedules, and 24/7 customer support, giving factories peace of mind and assurance that their production processes remain seamless. Cutting-edge oil boiler technologies often incorporate advanced digital controls and automation systems. These systems allow for precise monitoring and management of heat production, contributing to enhanced safety and efficiency within the factory. Automation minimizes human error and optimizes fuel usage, further establishing the oil boiler as a trusted, reliable component of the plywood production infrastructure. The shift towards sustainable manufacturing practices has also influenced the evolution of oil boilers. Today's modern oil boilers are designed with enhanced emission control capabilities, significantly reducing the release of harmful pollutants and aligning with global environmental standards. This progress in boiler technology not only assists factories in reducing their carbon footprint but also opens doors to new markets that prioritize green and sustainable production. In conclusion, the role of an oil boiler in a plywood factory extends beyond merely supplying heat. It is a critical component that influences the entire production efficiency, energy consumption, and environmental impact of the operations. By leveraging advanced boiler technologies, tapping into industry expertise, and prioritizing trustworthy partnerships, plywood manufacturers can achieve a sustainable and cost-effective production environment that meets both current operational demands and future growth objectives.

Latest news

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025

-

High-Efficiency Electric Steam Boiler Reliable Products & Service Leading CompaniesNewsJul.06,2025

-

High-Efficiency Biomass Pellet Boiler Reliable Steam Boiler Service & QuotesNewsJul.06,2025

-

High-Efficiency Thermal Oil Boiler for Asphalt Plant – Reliable Supplier & Factory Direct ProductNewsJul.06,2025