Jan . 19, 2025 03:32

Back to list

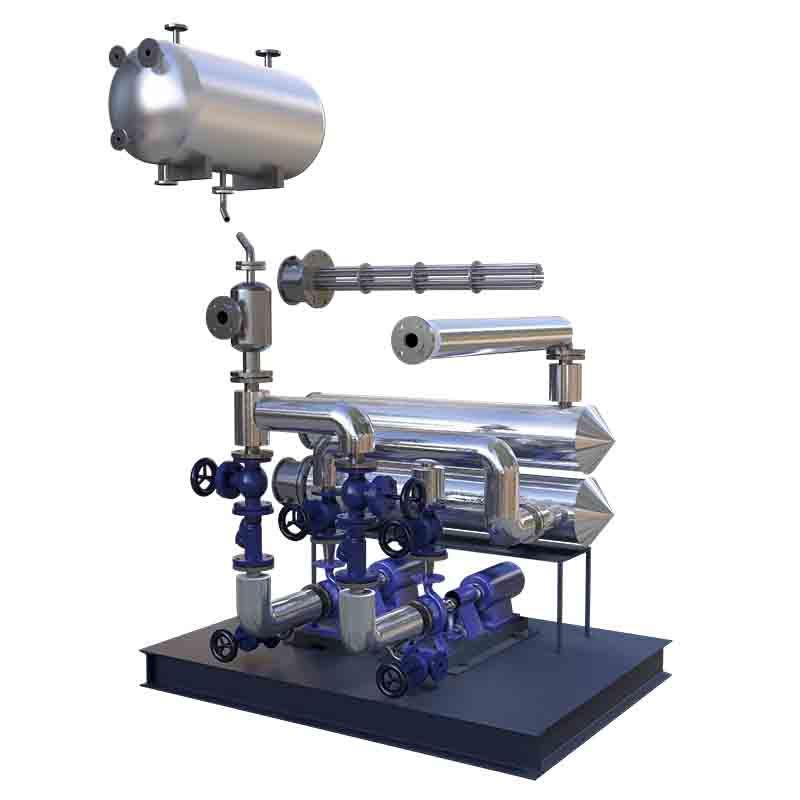

thermal oil boiler for press machine

Thermal oil boilers have emerged as indispensable components in various industrial applications, notably in press machines. These specialized boilers provide a crucial advantage in maintaining the optimal temperature for press operations, ensuring product quality and operational efficiency. This discussion centers on understanding the essential role of thermal oil boilers in press machines while emphasizing the key principles of experience, expertise, authoritativeness, and trustworthiness.

Authoritativeness through Industry Standards Industry standards and certifications provide a stamp of credibility to thermal oil boilers used in press machines. Companies manufacturing these boilers are often required to comply with stringent regulations such as the American Society of Mechanical Engineers (ASME) standards, ensuring safety and reliability. Reference to these standards not only enhances the authoritative nature of the product but also reassures users of the inherent safety benefits. Moreover, manufacturers collaborate with industrial safety experts to continually enhance the design and performance of thermal oil technologies. Trustworthiness through Proven Results Thermal oil boilers in press machine environments have consistently delivered reliable results. Trust is built through demonstrable performance metrics, including reduced downtime, consistent temperature maintenance, and energy savings. Testimonials from industry leaders confirm these advantages, noting significant improvements in production throughput and product quality. Companies leveraging thermal oil systems often report back on the impressive return on investment and lower operational costs, further solidifying the trust placed in these systems. In conclusion, the adoption of thermal oil boilers in press machines represents a strategic advantage for industries focused on precision and efficiency. The convergence of experience, expertise, authority, and trust has established this technology as a cornerstone in industrial heating solutions. By emphasizing reliability, adherence to standards, and consistent performance, thermal oil boilers have proven to be a trusted partner in advancing industrial excellence. As industries continue to evolve, the role of thermal oil systems is expected to expand, offering enhanced solutions that meet and exceed the demands of modern manufacturing environments.

Authoritativeness through Industry Standards Industry standards and certifications provide a stamp of credibility to thermal oil boilers used in press machines. Companies manufacturing these boilers are often required to comply with stringent regulations such as the American Society of Mechanical Engineers (ASME) standards, ensuring safety and reliability. Reference to these standards not only enhances the authoritative nature of the product but also reassures users of the inherent safety benefits. Moreover, manufacturers collaborate with industrial safety experts to continually enhance the design and performance of thermal oil technologies. Trustworthiness through Proven Results Thermal oil boilers in press machine environments have consistently delivered reliable results. Trust is built through demonstrable performance metrics, including reduced downtime, consistent temperature maintenance, and energy savings. Testimonials from industry leaders confirm these advantages, noting significant improvements in production throughput and product quality. Companies leveraging thermal oil systems often report back on the impressive return on investment and lower operational costs, further solidifying the trust placed in these systems. In conclusion, the adoption of thermal oil boilers in press machines represents a strategic advantage for industries focused on precision and efficiency. The convergence of experience, expertise, authority, and trust has established this technology as a cornerstone in industrial heating solutions. By emphasizing reliability, adherence to standards, and consistent performance, thermal oil boilers have proven to be a trusted partner in advancing industrial excellence. As industries continue to evolve, the role of thermal oil systems is expected to expand, offering enhanced solutions that meet and exceed the demands of modern manufacturing environments.

Latest news

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025

-

High-Efficiency Electric Steam Boiler Reliable Products & Service Leading CompaniesNewsJul.06,2025

-

High-Efficiency Biomass Pellet Boiler Reliable Steam Boiler Service & QuotesNewsJul.06,2025

-

High-Efficiency Thermal Oil Boiler for Asphalt Plant – Reliable Supplier & Factory Direct ProductNewsJul.06,2025