waste heat recovery boiler in cement plant

Waste Heat Recovery Boiler in Cement Plants Optimizing Energy Efficiency

Cement production is an energy-intensive process, accounting for approximately 7% of global carbon dioxide emissions, primarily due to the burning of fossil fuels. As the construction industry continues to expand, the demand for cement rises, making it crucial for manufacturers to optimize their energy usage. One of the most effective methods to enhance energy efficiency in cement plants is through the implementation of waste heat recovery (WHR) boilers.

Understanding Waste Heat Recovery

Waste heat recovery refers to the process of capturing and reusing heat that would otherwise be lost to the environment during industrial processes. In a cement plant, significant amounts of heat are generated during the pyroprocessing stage, where limestone and other materials are heated in a kiln to produce clinker. This high-temperature waste gas, typically released into the atmosphere, can be harnessed to generate steam, which can then be utilized to produce electricity or for other thermal applications within the plant.

How WHR Boilers Work

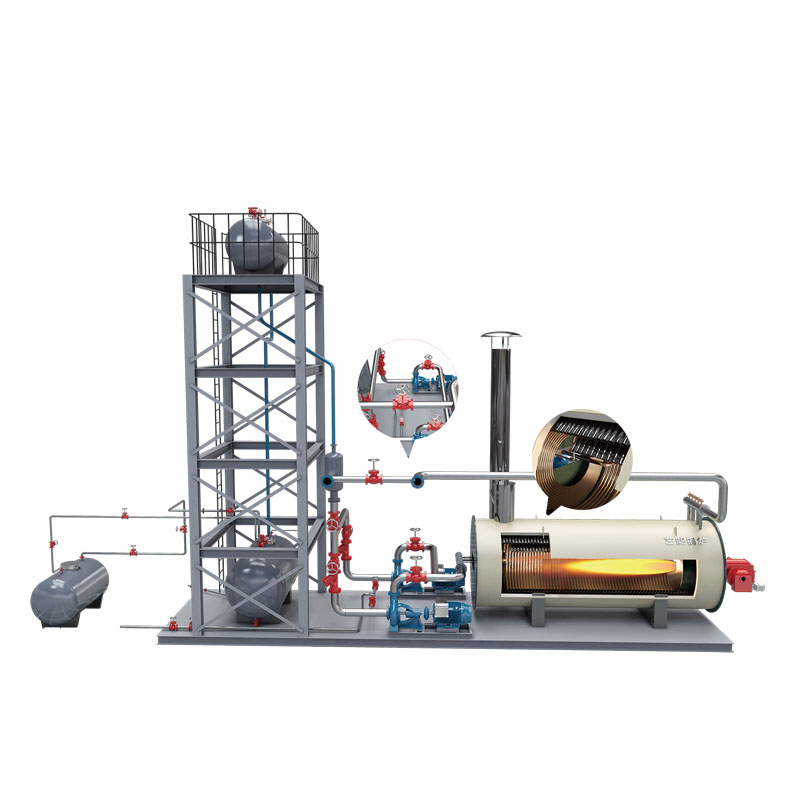

A waste heat recovery boiler (WHRB) operates by transferring the heat from hot exhaust gases to water or another fluid to produce steam. The system typically consists of a heat exchanger, a steam drum, and a turbine for electricity generation. The hot gases pass through the heat exchanger, where they transfer heat to the water circulating in tubes. This process not only generates steam but also cools the exhaust gases, thus reducing the overall temperature of harmful emissions released into the atmosphere.

By integrating WHR boilers into cement plants, manufacturers can significantly increase their energy efficiency. The steam produced can be used for driving turbines to generate electricity, which can reduce reliance on fossil fuels for power generation. In essence, WHR systems transform waste heat into valuable energy, contributing to a more sustainable cement production process.

Benefits of Implementing WHR Boilers

waste heat recovery boiler in cement plant

1. Energy Savings The introduction of WHR boilers can lead to substantial energy savings. Studies indicate that cement plants utilizing waste heat recovery systems can achieve a reduction in energy consumption by 20-30%, translating to lower operational costs.

2. Reduced Emissions By utilizing waste heat, cement plants can decrease their reliance on fossil fuels, thereby minimizing their carbon footprint. Since WHR systems lower the need for external energy sources, they help in complying with environmental regulations and promoting sustainability initiatives.

3. Increased Competitiveness In an industry where operational efficiency is paramount, integrating waste heat recovery can provide a competitive edge. Lower energy costs and reduced emissions enhance brand reputation and can steer potential investors and customers towards more eco-friendly operations.

4. Temperature Control WHR systems also aid in better temperature control of plant processes. By efficiently managing heat, cement manufacturers can ensure optimal conditions for clinker production, which improves product quality.

Challenges and Considerations

Despite the clear advantages, the implementation of WHR boilers is not without challenges. The initial capital investment for installing WHR systems can be substantial. Moreover, the integration process requires careful consideration of system design, maintenance, and operational adjustments. Effectively managing the thermal efficiency and ensuring reliability of the system are essential for long-term success.

Conclusion

The adoption of waste heat recovery boilers in cement plants presents an opportunity for enhanced energy efficiency, reduced emissions, and cost savings. As the industry moves towards more sustainable practices, integrating WHR systems will not only contribute to environmental goals but will also improve the profitability and competitiveness of cement manufacturers. As technology advances and the global focus on sustainability grows, waste heat recovery will likely play an increasingly crucial role in the future of cement production.

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025