500kg Steam Boiler Manufacturers and Their Innovations in Industrial Applications

An Overview of 500 Kg Steam Boiler Factories

Steam boilers are vital components in various industries, serving as a crucial source of heat energy for numerous applications. Among the various types of steam boilers, the 500 kg steam boiler is particularly notable due to its efficiency and versatility. This article delves into the significance of 500 kg steam boiler factories, their operational characteristics, and their impact on industry.

Understanding the 500 Kg Steam Boiler

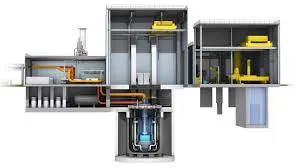

A 500 kg steam boiler is designed to generate steam at a capacity of 500 kilograms per hour. This capacity is often sufficient for small to medium-sized industrial applications, including food processing, textile manufacturing, and chemical production. These boilers operate by heating water through combustion processes, converting it into steam, which can then be utilized for heating, power generation, or driving machinery.

The efficiency of a 500 kg steam boiler lies in its design and operational capabilities. Typically, these boilers feature advanced combustion technology that optimizes fuel use, reducing emissions and lowering operational costs. Furthermore, modern boilers are often equipped with sophisticated control systems that enable precise regulation of temperature and pressure, enhancing safety and ensuring compliance with environmental regulations.

The Role of 500 Kg Steam Boiler Factories

500 kg steam boiler factories play a critical role in the manufacturing and distribution of these essential units. These factories are equipped with advanced technology and skilled professionals who specialize in the design, engineering, and production of steam boilers. The manufacturing process involves several key steps

1. Research and Development This initial phase focuses on designing boilers that meet industry standards and customer requirements. Engineers and designers collaborate to enhance the efficiency and functionality of the boilers.

2. Material Selection Quality raw materials are essential for building reliable steam boilers. Factories typically source high-grade steel and other materials to ensure durability and safety.

500kg steam boiler factories

3. Manufacturing Process The construction of a steam boiler involves various processes, including welding, assembly, and installation of crucial components such as burners, economizers, and safety devices. Modern factories employ precision machinery to enhance product quality and reduce production time.

4. Testing and Quality Control Before reaching the market, each steam boiler undergoes rigorous testing to ensure it meets safety and performance standards. This involves checking for leaks, pressure resistance, and thermal efficiency.

5. Customization and Service Many factories offer customization options to cater to the specific needs of different industries. After-sales service, including maintenance and repair, is also a critical aspect of boiler factories, ensuring prolonged operational efficiency for their clients.

Industry Impact and Sustainability

The presence of 500 kg steam boiler factories has a significant impact on the industrial landscape. By providing efficient and reliable steam solutions, these factories contribute to the productivity of various sectors. Moreover, they play a part in the global effort to promote sustainability. Many modern boilers are designed to utilize renewable energy sources or alternative fuels, aligning with environmental policies and reducing carbon footprints.

Industries that leverage 500 kg steam boilers benefit from improved energy efficiency, which translates to lower operational costs and enhanced competitiveness. Furthermore, the introduction of innovative technologies, such as heat recovery systems and automated control mechanisms, ensures that these boilers operate at optimal performance levels.

Conclusion

In summary, 500 kg steam boiler factories are instrumental in meeting the energy needs of diverse industries. Their commitment to producing high-quality, efficient, and environmentally friendly steam boilers not only bolsters industrial productivity but also supports sustainability efforts. As industries continue to evolve, the role of these factories in providing reliable and innovative steam solutions will undoubtedly remain pivotal in fostering economic growth and environmental stewardship.

-

Industrial Steam Boiler Corporation - Reliable Industrial Boiler Manufacturer & SupplierNewsJul.08,2025

-

High-Efficiency Steam Boiler Heat Exchanger Supplier & Factory Durable Products for IndustryNewsJul.08,2025

-

Premium Electric Steam Boiler Manufacturer Reliable Company & Factory SolutionsNewsJul.08,2025

-

Commercial Hot Water Boiler - Reliable Supplier & Factory Direct Price for Efficient Heating SolutionsNewsJul.07,2025

-

Top Hot Oil Boiler Manufacturer - Reliable Thermal Oil & Coal Fired Boiler Manufacturer ManufacturerNewsJul.07,2025

-

High-Efficiency Hotel Hot Water Boiler – Leading Exporters & Quotes for HotelsNewsJul.07,2025