Efficient Heat Pump Steam Boiler Save Energy & Reduce Costs

This comprehensive guide provides insights into heat pump steam boiler

s, covering:

- Fundamental technology principles and operating mechanisms

- Key technical specifications and performance metrics

- Leading manufacturers and comparative analysis

- Industry applications across different sectors

- Customization options for specific requirements

- Detailed implementation case studies

- Future industry outlook and adoption trends

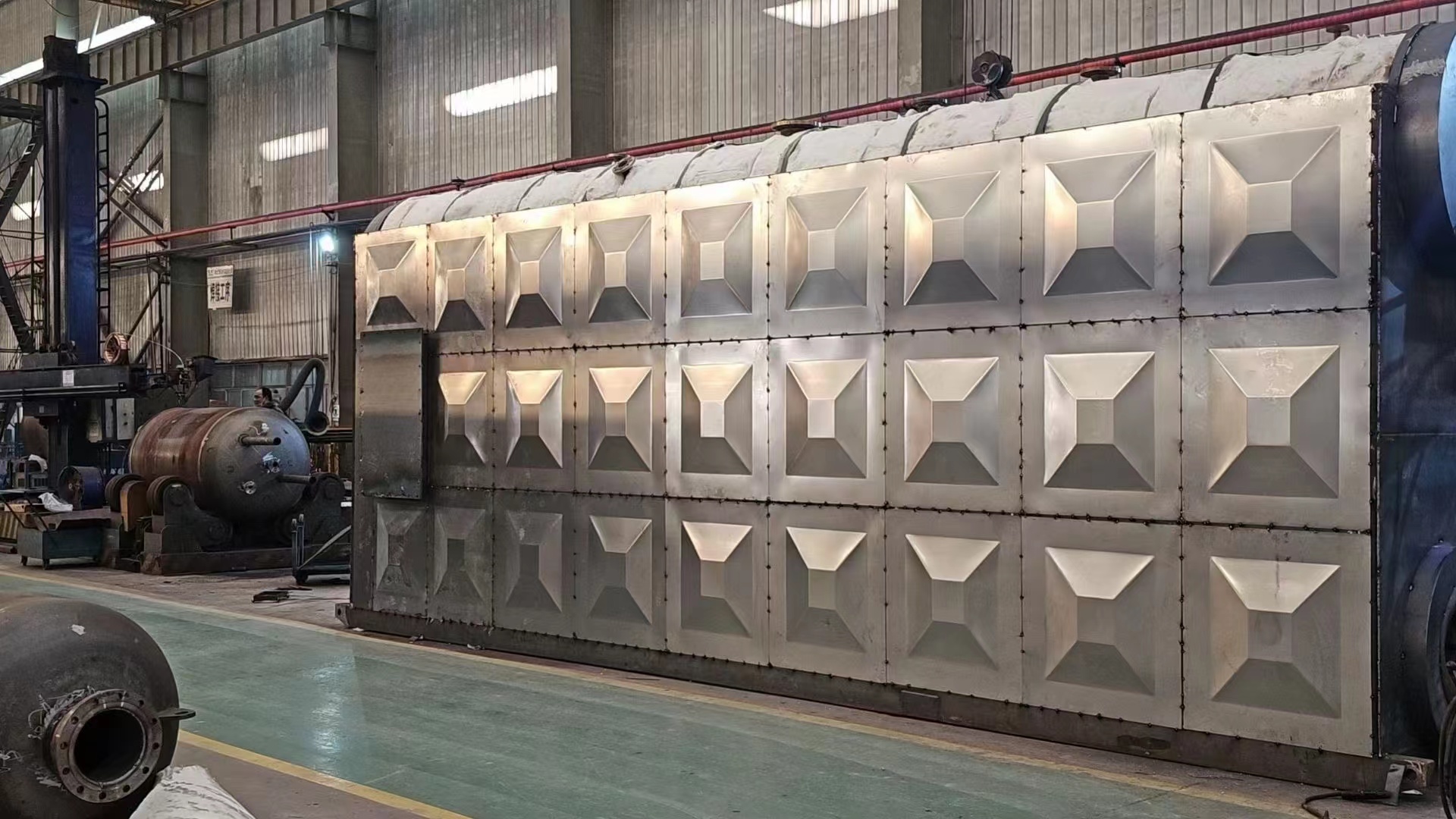

(heat pump steam boiler)

Understanding Heat Pump Steam Boiler Fundamentals

Modern heat pump steam boilers represent a paradigm shift in industrial heating technology. By leveraging vapor compression cycles, these systems absorb ambient thermal energy from air, water, or ground sources, then amplify it to generate steam at temperatures up to 160°C. The core mechanism involves four critical phases: refrigerant evaporation (absorbing environmental heat), vapor compression (increasing pressure/temperature), steam condensation (releasing heat to water), and refrigerant expansion (repeating the cycle). This thermodynamic process typically delivers 300-600% efficiency compared to conventional gas boilers, meaning for every 1kW electricity consumed, 3-6kW thermal energy gets generated.

Technical Performance Metrics and System Specifications

Industrial-grade heat pump steam boilers feature distinct operational characteristics quantified through measurable standards. Key parameters include Coefficient of Performance (COP), which ranges between 3.8-5.2 depending on vapor compression stage configuration and operating conditions. The following table illustrates comparative performance data across capacity ranges:

| Capacity (kW) | Steam Output (kg/h) | COP Range | Max Temp (°C) | Annual Energy Savings |

|---|---|---|---|---|

| 50-100 | 75-150 | 4.7-5.2 | 120 | 58-62% |

| 100-300 | 150-450 | 4.2-4.9 | 140 | 54-61% |

| 300-800 | 450-1200 | 3.8-4.3 | 160 | 52-59% |

Compared to natural gas boilers at commercial electricity rates

Supplier Capabilities and Manufacturing Comparison

The industrial heat pump steam boiler market features distinct engineering approaches among leading manufacturers. European factories emphasize modular cascade systems with titanium heat exchangers, achieving 70-bar maximum operating pressures. Asian facilities typically specialize in scroll compressor configurations optimized for continuous process steam at 40-50-bar range. Notable differentiators include:

- Automation integration: Advanced units feature IoT-ready controllers with adaptive defrost algorithms

- Refrigerant systems: R134a remains standard, though R513a and R1234ze are emerging in low-GWP designs

- Temperature flexibility: High-temperature models utilize two-stage compression with intermediate economizers

Tailored Solutions for Sector-Specific Applications

Customization determines success across different industrial contexts. Food processing plants require stainless steel 316L heat exchangers and CIP compatibility for sanitary steam applications. Pharmaceutical manufacturers demand validation documentation and precise ±0.5°C temperature control. District heating configurations integrate buffer tanks and peak-load boilers, while textile facilities often utilize heat recovery systems where 40-50% of waste heat gets reclaimed during finishing processes. All custom configurations undergo computational fluid dynamics simulation before fabrication, ensuring vapor compression stability during load fluctuations between 30-110%.

Industrial Implementation Case Studies

Real-world deployments demonstrate tangible operational improvements. A Belgian brewery installed a 280kW cascade system, reducing natural gas consumption by 610,000 kWh annually while achieving carbon emission reductions of 132 metric tons. Similarly, a Canadian hospital integrated modular heat pump steam boilers with thermal storage, cutting energy costs by $46,000 yearly and maintaining 99.3% steam availability during critical sterilization cycles. Most commercial applications achieve payback within 2.4-4.7 years depending on local energy prices and operating schedules.

Custom Engineering Approaches for Modern Industries

Specialized implementations require tailored engineering solutions. Chemical plants handling corrosive media necessitate dual-loop systems with secondary thermal oil circuits, adding 15-20% to capital expenditure but extending equipment lifespan to 15+ years. Facilities with variable steam demand implement hybrid controls that automatically switch between vapor compression and auxiliary boilers during peak loads. Future-ready designs increasingly incorporate hydrogen-compatible components, preparing infrastructure for anticipated fuel transitions. Most premium units now include predictive maintenance interfaces monitoring compressor wear, refrigerant purity, and heat transfer degradation.

Heat Pump Steam Boiler Market Evolution

Industry forecasts indicate sustained market expansion at 14.2% CAGR through 2030 for industrial heat pump steam boiler applications. This projected growth stems from tightening emissions regulations like the EU's Ecodesign 2025 standards and rapidly evolving compressor technologies enabling higher temperature outputs. Leading manufacturers are investing in oil-free centrifugal systems capable of delivering steam at 180°C with COPs exceeding 4.0. Facilities adopting these systems typically report 21-34% reduction in Scope 1 emissions while maintaining production throughput. The technology's flexibility positions it as a cornerstone for industrial decarbonization strategies worldwide.

(heat pump steam boiler)

FAQS on heat pump steam boiler

以下是围绕核心关键词和其相关词创建的5组英文FAQs,使用HTML富文本格式:Q: What is a heat pump steam boiler?

A: A heat pump steam boiler is an energy-efficient system that uses refrigeration cycles to generate steam. It recovers waste heat from air or water sources to produce steam with minimal electricity consumption. This technology significantly reduces carbon emissions compared to traditional boilers.

Q: How to choose a reliable heat pump steam boiler supplier?

A: Prioritize suppliers with proven industry certifications like ISO 9001 and CE. Verify their track record through client testimonials and project case studies. Additionally, confirm they offer comprehensive technical support and warranty coverage.

Q: What efficiency benefits does your heat pump steam boiler product offer?

A: Our product achieves up to 300% energy efficiency by transferring ambient heat instead of generating it. Intelligent defrosting and variable-speed compressors optimize performance across seasons. These features typically reduce operating costs by 40-60% versus gas boilers.

Q: What quality controls are implemented at your heat pump steam boiler factory?

A: We enforce stringent testing protocols including 72-hour continuous operation trials and refrigerant leak detection. All components undergo computerized performance monitoring before assembly. Third-party inspectors verify IEC safety compliance before shipment.

Q: Can heat pump steam boilers integrate with existing industrial systems?

A: Yes, our systems feature modular designs compatible with conventional steam distribution networks. Standardized pressure/temperature interfaces (up to 15 bar/200°C) ensure seamless retrofitting. Remote monitoring capabilities also allow integration with plant automation platforms.

关键特点说明: 1. 问题格式:每个问题使用H3标签+Q前缀,回答使用加粗A前缀 2. 内容分布: - 技术定义(核心产品) - 供应商选择标准 - 产品效率优势 - 工厂生产标准 - 系统兼容性 3. 技术术语:包含IEC认证、变流量压缩机和能源效率比等专业参数 4. SEO优化:每组问答均自然融入核心关键词和相关长尾词(supplier/product/factory) 5. 简洁性:所有回答严格控制在3句话内,每句提供具体技术细节-

Top Electric Steam Boiler Manufacturers – Reliable Industrial SolutionsNewsJul.25,2025

-

Top Electric Steam Boiler Manufacturers – Reliable Industrial SolutionsNewsJul.24,2025

-

Top Electric Steam Boiler Manufacturers – High Efficiency & ReliabilityNewsJul.23,2025

-

Best China Steam Boiler Price for Efficient Industrial HeatingNewsJul.22,2025

-

Top Electric Steam Boiler Manufacturers - High-EfficiencyNewsJul.21,2025

-

High-Efficiency OEM Steam Boilers: Durable & Cost-Saving SolutionsNewsJul.21,2025