odm coal fired thermal oil heater

Understanding the ODM Coal Fired Thermal Oil Heater

As industries evolve, the demand for efficient heating solutions has become increasingly pivotal in various sectors, particularly in processes that require high temperatures. One such solution that has garnered attention is the ODM coal-fired thermal oil heater. This innovative system combines traditional coal-fired heating technologies with modern thermal oil heating principles, offering a highly efficient and reliable source of thermal energy.

What is a Coal Fired Thermal Oil Heater?

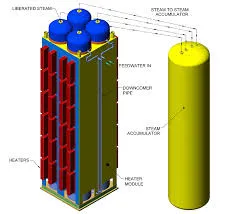

A coal-fired thermal oil heater operates using coal as its primary fuel source to heat thermal oil. Unlike conventional steam boilers, which produce steam for heating, thermal oil heaters utilize oil as the heat transfer fluid. This method allows for precise temperature control and minimizes energy loss, making it suitable for high-temperature applications such as chemical processing, food production, and textile manufacturing.

The thermal oil is circulated through a system of pipes, absorbing heat at the furnace and transferring it to various industrial processes. This eliminates the need for high-pressure steam systems, making the operation safer and more efficient.

Advantages of ODM Coal Fired Thermal Oil Heaters

1. Efficiency ODM coal-fired thermal oil heaters are designed to operate at high efficiencies, often exceeding 80%. This maximizes the useful energy extracted from the coal, reducing fuel consumption and operational costs.

2. High-Temperature Performance These heaters can achieve temperatures of up to 400°C or more, providing the high-temperature heat needed for various industrial processes. The ability to operate at elevated temperatures without high pressure makes them suitable for demanding applications.

3. Versatility Thermal oil heaters can be used across various industries. From food processing to petrochemical applications, their versatility makes them an essential tool for many manufacturers. The ability to finely control temperatures also means they can be customized for specific process needs.

odm coal fired thermal oil heater

4. Safety The design of thermal oil heating systems minimizes the risk of explosions and accidents associated with high-pressure steam systems. The operation is safer, with reduced chances of catastrophic failures.

5. Cost-Effective Operation Utilizing coal as a fuel source can often be more economical compared to natural gas or electricity, particularly in regions where coal is readily available. This can significantly lower heating costs for manufacturers.

6. Sustainability Considerations With advancements in technology, modern ODM coal-fired thermal oil heaters can incorporate emissions control systems that help reduce the environmental impact. By capturing and recycling flue gases, these heaters can operate more sustainably.

Operational Considerations

Operating a coal-fired thermal oil heater requires careful management. It’s crucial to maintain optimal combustion conditions to ensure complete burning of coal, which helps in minimizing emissions and maximizing thermal efficiency. Regular maintenance and cleaning of the system are necessary to avoid buildup of soot and other particulates which can impede performance.

Additionally, operators must adhere to safety protocols, as handling coal and operating any form of combustion system carries inherent risks. Proper training for personnel and investment in safety systems can mitigate these hazards.

Conclusion

The ODM coal-fired thermal oil heater represents a robust solution for industries requiring high-temperature heat with a focus on efficiency and safety. Its combination of traditional coal firing technology with the benefits of thermal oil heating makes it an attractive option for many applications ranging from manufacturing to power generation.

As industries look toward optimizing their processes and reducing costs, the role of advanced heating solutions like the ODM coal-fired thermal oil heater will undoubtedly continue to grow. With careful management and adherence to safety practices, these systems offer a powerful, cost-effective solution for meeting today’s thermal energy demands.

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025