plc control boiler product

PLC Control in Boiler Systems Enhancing Efficiency and Safety

In the realm of industrial automation, Programmable Logic Controllers (PLCs) have revolutionized the way complex systems are managed and monitored. One of the significant applications of PLCs is in the control of boiler systems. Boilers are fundamental components in various industries, serving vital roles in processes ranging from manufacturing to power generation. With the introduction of PLC control, boilers can now be operated more efficiently, safely, and reliably.

Understanding PLCs

A PLC is an industrial computer specifically designed for controlling manufacturing processes. It utilizes programmable memory to store instructions and implement various functions such as logic operations, sequencing, timing, counting, and arithmetic operations. PLCs can operate under harsh environments, making them particularly suited for industrial applications where reliability is crucial.

The Role of PLCs in Boiler Control

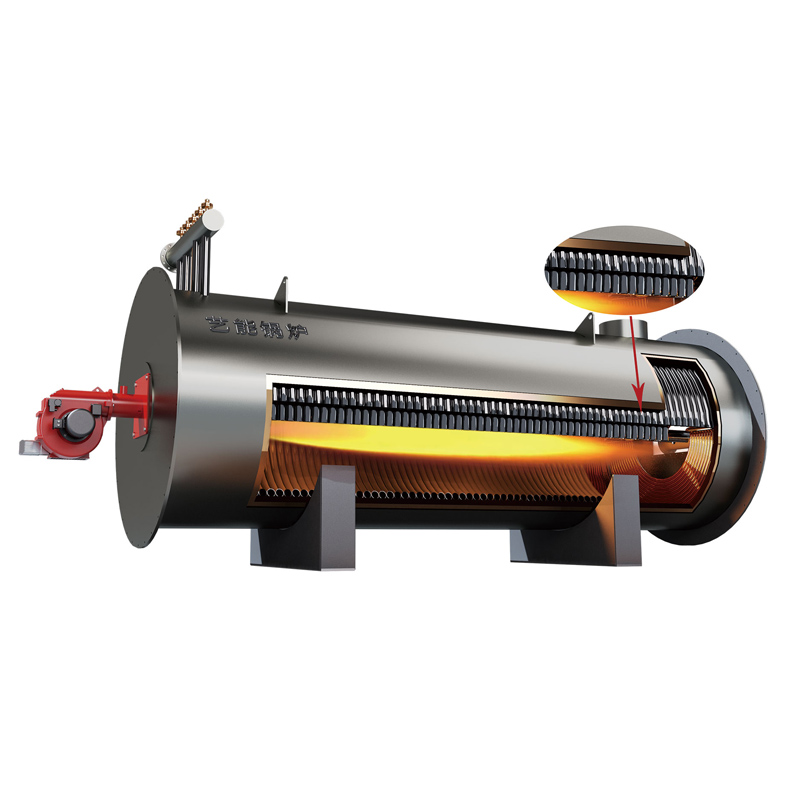

Boiler systems are complex assemblies that require precise control to ensure optimal performance. Traditional control methods often rely on manual operation or basic relay systems, which can lead to inefficiencies and safety risks. By employing PLCs in boiler control, operators can

1. Achieve Greater Precision PLCs can monitor various parameters, including temperature, pressure, and flow rates, with high accuracy. This enables operators to maintain setpoints effectively, leading to improved efficiency and reduced fuel consumption.

2. Automate Processes Automation of boiler operations is one of the significant advantages of PLC implementation. PLCs can execute pre-programmed sequences for startup, shutdown, and operational adjustments, minimizing the risk of human error. For instance, the automation of fuel feed based on real-time demand can optimize resource consumption.

plc control boiler product

3. Enhance Safety Safety is paramount when dealing with high-pressure and high-temperature systems like boilers. PLCs can be integrated with various safety devices, such as pressure relief valves and temperature sensors, to provide immediate responses to potentially hazardous conditions. If a parameter exceeds safe limits, the PLC can automatically shut down the system or activate safety protocols, protecting both personnel and equipment.

4. Facilitate Remote Monitoring and Control With advancements in technology, modern PLCs can be equipped with communication capabilities that allow for remote monitoring and control. Operators can access real-time data from anywhere, enabling them to make informed decisions quickly. This remote access is particularly beneficial for large plants where centralized control is necessary.

5. Integrate with Other Systems PLCs can seamlessly connect with other industrial control systems, such as SCADA (Supervisory Control and Data Acquisition) and MES (Manufacturing Execution Systems). This integration allows for comprehensive data analysis, enabling operators to optimize boiler performance and overall plant efficiency by responding to changing conditions and production demands.

Environmental Considerations

The implementation of PLCs in boiler control also contributes to sustainability initiatives. By optimizing combustion processes and reducing emissions, PLC-controlled boilers can help industries comply with environmental regulations. Additionally, improved fuel efficiency directly translates to lower operational costs and reduced carbon footprints.

Conclusion

The integration of PLC control in boiler systems marks a significant advancement in industrial automation. This technology enhances operational efficiency, promotes safety, and supports environmental sustainability, making it an indispensable tool in modern industrial applications. As industries continue to evolve, the role of PLCs in managing boiler systems will undoubtedly expand, paving the way for smarter, greener, and more efficient manufacturing processes. Investing in PLC technology not only prepares companies for current demands but also positions them favorably for future challenges in the industrial landscape.

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025