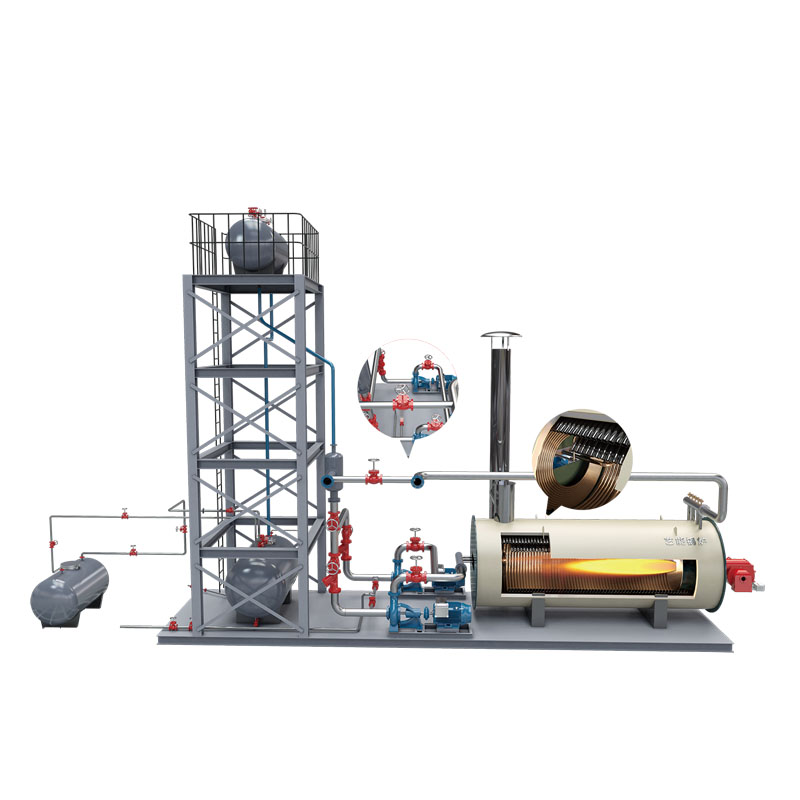

industrial water boiler product

Industrial Water Boilers An Overview

Industrial water boilers play a crucial role in a variety of industries, providing essential heat and steam for processes ranging from power generation to food production. Understanding the fundamentals of these systems is vital for industries looking to optimize their operations, enhance energy efficiency, and ensure compliance with environmental regulations.

Types of Industrial Water Boilers

Industrial water boilers can be classified into several types based on their design and intended use. The most common types include

1. Fire-Tube Boilers In fire-tube boilers, hot gases from combustion pass through tubes that are surrounded by water. This design is simple, efficient, and well-suited for low-pressure applications. Fire-tube boilers are often used in smaller industrial operations due to their compact size and ease of maintenance.

2. Water-Tube Boilers Unlike fire-tube boilers, water-tube boilers have water-filled tubes that are heated by the combustion gases. This design allows them to operate at higher pressures and temperatures, making them ideal for large-scale industries that require a significant amount of steam.

3. Electric Boilers Electric boilers use electricity as a heat source to produce steam or hot water. They are favored for applications where emissions must be minimized or where gas supply is unavailable. Electric boilers are often used in combination with renewable energy sources, enhancing sustainability efforts.

4. Biomass Boilers These boilers utilize organic materials such as wood pellets, agricultural waste, or other biomass for fuel. Biomass boilers are becoming increasingly popular as industries aim to reduce their carbon footprint and transition towards more sustainable energy sources.

Efficiency and Sustainability

One of the primary concerns for industrial water boiler operation is efficiency. High-efficiency boilers can significantly reduce fuel consumption and operational costs while lowering greenhouse gas emissions. The efficiency of a boiler is often expressed as the annual fuel utilization efficiency (AFUE), which measures the percentage of fuel converted to usable heat.

industrial water boiler product

To enhance sustainability, many manufacturers are developing advanced boiler technologies, such as condensing boilers that capture and reuse waste heat. Moreover, implementing regular maintenance protocols ensures optimal performance and prolongs the lifespan of the boiler. It is also essential to train personnel on best practices for system operation and maintenance.

Regulatory Compliance

Industrial water boilers are subject to various regulations aimed at reducing emissions and ensuring safety. Compliance with environmental regulations is critical for industries, especially those in regions with strict air quality standards. Monitoring systems can be implemented to track emissions and ensure that the boiler operation aligns with local regulations.

Additionally, safety standards must be adhered to in boiler operations. The American Society of Mechanical Engineers (ASME) governs many aspects of boiler safety, including design, manufacturing, and maintenance. Regular inspections and certifications help mitigate risks associated with boiler explosions or failures.

Innovations in Boiler Technology

The future of industrial water boilers is being shaped by innovations such as automation and smart technology integration. Smart boilers equipped with sensors and IoT connectivity enable real-time monitoring and data analytics. This technology allows operators to make informed decisions about energy usage, maintenance schedules, and system efficiency.

Furthermore, the shift towards decarbonization is prompting research into alternative fuels and hybrid systems that combine traditional fossil fuels with renewable sources. These advancements not only promise improved efficiency but also enhance the sustainability of industrial processes.

Conclusion

In conclusion, industrial water boilers are a vital component of various industries, providing essential heat and steam for numerous processes. As technology advances, the focus on efficiency, sustainability, and regulatory compliance continues to rise. By understanding the different types of boilers, prioritizing maintenance, and embracing innovation, industries can ensure that their boiler systems operate effectively and responsibly. As businesses navigate the challenges of a changing energy landscape, investing in modern boiler technologies will be key to achieving operational excellence and environmental stewardship.

-

Efficient Thermal Oil Boilers with AI Optimization | Superior PerformanceNewsAug.03,2025

-

High-Efficiency OEM Steam Boilers w/GPT-4-TurboNewsAug.02,2025

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025