Oil Boiler Solutions for Efficient Plywood Factory Production and Manufacturing Processes Optimization

Choosing the Right Oil Boiler for Plywood Factory Manufacturers

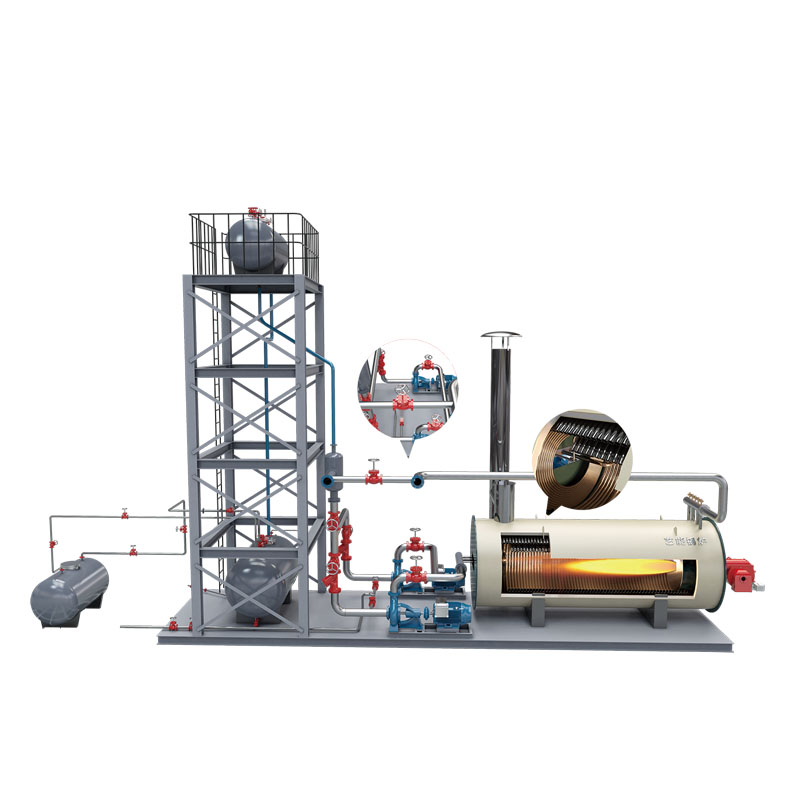

In the plywood manufacturing industry, efficiency and reliability are paramount. The production process often requires significant heat energy for drying and curing processes. One of the most effective solutions for providing this energy is an oil boiler. Tailored to meet the specific needs of plywood factory manufacturers, oil boilers offer numerous benefits, including high efficiency, consistent performance, and ease of maintenance.

The Importance of Oil Boilers in Plywood Manufacturing

Plywood production involves several steps, including log debarking, peeling, drying, and pressing. Each of these stages requires precise temperature control, especially during the drying process to prevent defects in the final product. Liquid fuel oil is particularly advantageous in this sector due to its energy density and the ability to produce high-temperature steam and hot water needed for drying wood sheets effectively.

Oil boilers can generate substantial amounts of hot water and steam, which are crucial for maintaining the required temperatures in various processes. When implemented correctly, these systems enhance the overall production efficiency and can significantly reduce energy costs.

Efficiency and Design Considerations

When selecting an oil boiler, manufacturers must consider efficiency ratings. High-efficiency boilers not only reduce fuel consumption, which can lead to lower operational costs but also minimize harmful emissions that can arise during combustion. Manufacturers often seek out units with minimum efficiency ratings set by environmental regulations, ensuring they remain compliant while also contributing to sustainability efforts in their operations.

Design features also play a critical role in the selection of an oil boiler. Modern designs include features such as advanced combustion technology, which optimizes fuel usage and reduces smoke emissions. Automatic controls, often integrated into these systems, enable precise temperature management and can adjust the heating output based on real-time production demands.

oil boiler for plywood factory manufacturers

Reliability and Maintenance

Reliability is a key consideration in any manufacturing process, and this holds particularly true for plywood factories. Oil boilers are typically designed for heavy-duty applications with robust construction materials that withstand the rigors of continuous operation. However, even the best equipment requires routine maintenance to ensure peak performance.

Choosing manufacturers that offer comprehensive maintenance services and support is crucial. Regular maintenance checks, including inspections, cleaning, and part replacements, are essential to prevent unexpected downtimes, which can disrupt production schedules and lead to financial losses. Some manufacturers also offer predictive maintenance options, using advanced sensors and AI technology to foresee potential issues before they escalate.

Environmental Considerations

In an era of increasing environmental awareness, opting for oil boilers equipped with emissions control technologies can drastically reduce the environmental footprint of plywood manufacturing. Many oil boilers now come with features like flue gas recirculation and electronic air-fuel mixing systems that significantly lower nitrogen oxides (NOx) and particulate emissions. Choosing such systems not only complies with regulatory standards but also enhances the company’s reputation among consumers increasingly concerned about sustainability.

Conclusion

For plywood factory manufacturers, selecting the right oil boiler is fundamental to achieving operational efficiency and environmental responsibility. With advancements in technology, the modern oil boiler ensures high efficiency, reliability, and reduced emissions. By understanding their specific heating needs, manufacturers can make informed decisions that not only enhance productivity but also align with their sustainability goals. Partnering with reputable oil boiler manufacturers who provide ongoing support and innovative solutions can lead to long-term benefits for plywood manufacturing businesses.

-

High-Efficiency House Hot Water Boiler Supplier & Factory Reliable House Hot Water Boiler Product SolutionsNewsJul.04,2025

-

Top Boiler Dealer & Supplier Quality Boiler Dealer Products from Factory DirectNewsJul.04,2025

-

High-Efficiency Waste Heat Recovery Boiler Expert Service & QuotesNewsJul.04,2025

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025