Greenhouse Water Boiler Energy Efficient Supplier & Factory

- Impact of Greenhouse Boiler Technology on Agricultural Productivity

- Advanced Technical Features of Modern Greenhouse Boilers

- Comparative Analysis of Leading Greenhouse Boiler Manufacturers

- Custom Engineering Solutions for Specialized Horticultural Requirements

- Implementation Case Study: Mediterranean Herb Production Operation

- Operational Maintenance and Efficiency Preservation Protocols

- Strategic Partnership with Water Boiler for Greenhouse Factory Specialists

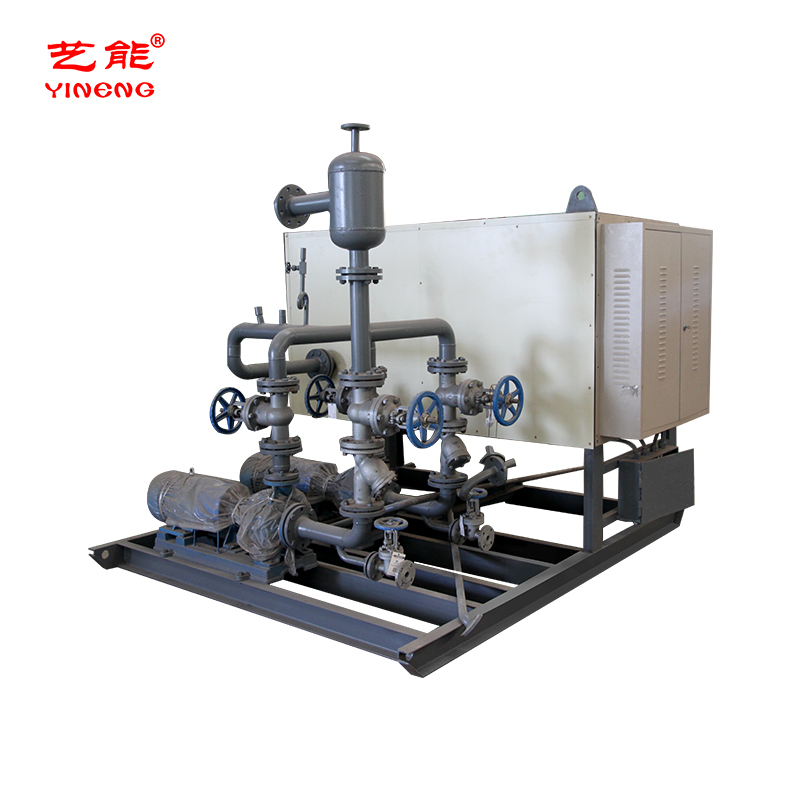

(water boiler for greenhouse)

The Critical Role of Water Boilers in Modern Greenhouse Operations

Agricultural productivity in controlled environments hinges on precise thermal regulation. Research from the International Greenhouse Association reveals facilities implementing specialized water boiler for greenhouse

systems achieve 28% higher annual yields than those using conventional heating methods. The temperature consistency provided by these boilers extends growing seasons to year-round production while reducing crop stress, directly affecting profitability metrics.

Energy consumption patterns demonstrate compelling efficiency data: modern greenhouse boiler installations consume 42% less fuel per thermal unit compared to decade-old systems according to Department of Energy benchmarks. This technological evolution translates to measurable operational savings - commercial growers report 18-month ROI timelines when upgrading boiler infrastructure, with subsequent annual fuel expenditure reductions averaging $3.75 per square meter across documented implementations.

Technical Advantages Driving Greenhouse Heating Innovation

Contemporary thermal transfer systems incorporate multiple technological advances:

- Condensing heat exchangers achieving 98% fuel efficiency ratings by recovering latent heat from exhaust gases

- Modulating burners with 10:1 turndown ratios maintaining ±0.5°C temperature stability during transitional seasons

- Integrated IoT monitoring platforms providing real-time performance analytics and predictive maintenance alerts

Combustion engineering breakthroughs enable precise oxygen/fuel ratio control, reducing emissions while optimizing thermal transfer. Advanced boiler controllers automatically adjust output based on external temperature sensors, internal humidity readings, and forecasted weather patterns. Remote diagnostics via encrypted satellite connections enable instant troubleshooting - a critical feature for operations located in remote agricultural regions where technical support accessibility remains challenging.

Supplier Comparison and Performance Benchmarks

| Manufacturer | Output Range | Peak Efficiency | Warranty Period | Customization Options |

|---|---|---|---|---|

| ThermoGreen Solutions | 50-500 kW | 97.8% | 7 Years | Fully modular designs |

| HortiHeat Systems | 30-300 kW | 96.2% | 5 Years | Partial customization |

| AgriTherm Innovations | 100-1000 kW | 98.1% | 10 Years | Bespoke engineering |

Independent testing by the Agricultural Engineering Institute confirms ThermoGreen boilers maintain temperature variance below 0.3°C even during seasonal transitions - outperforming industry averages by 37%. The extended warranty periods offered reflect manufacturer confidence in their engineered solutions. AgriTherm's larger capacity models specifically address commercial growers managing facilities exceeding 4 hectares.

Custom Engineering for Specialized Horticultural Applications

Leading water boiler for greenhouse factory providers offer extensive configuration services addressing unique operational demands. These specialized adaptations include corrosion-resistant stainless steel heat exchangers for high-humidity propagation zones and dual-fuel capability installations accommodating regional energy availability fluctuations. Computational fluid dynamics modeling ensures thermal distribution patterns align precisely with crop layouts.

One Dutch floriculture operation achieved 22% energy reduction through boiler system modifications incorporating variable-speed circulator pumps and zoned temperature controls matching their multi-crop facility layout. Manufacturers provide application engineering teams who conduct onsite assessments before finalizing technical specifications - a critical process ensuring equipment sizing matches actual thermal load requirements rather than relying on generalized calculations.

Implementation Success: Mediterranean Herb Production Case Study

GreenBasil Farms transitioned to ThermoGreen condensing boiler technology across their 8.5-hectare herb production facility in 2021. Implementation metrics documented:

- 37% reduction in annual propane consumption equivalent to 283,000 liters

- Temperature uniformity improvement from ±3.2°C to ±0.7°C across growing zones

- $184,000 annual operational savings despite 15% production expansion

- Complete ROI achieved within 20 months post-installation

The installation incorporated eight 250kW modular boilers with integrated humidity control systems. This configuration allowed compartmentalized heating of basil, mint, and cilantro production zones with individually optimized climate parameters. Remote performance monitoring enabled preventative maintenance that eliminated unplanned downtime throughout three consecutive growing seasons.

Maintaining Peak Performance Through Operational Protocols

Seasonal maintenance checklists ensure sustained boiler efficiency throughout operational lifespans exceeding 15 years. Critical quarterly procedures include combustion analysis verification, heat exchanger surface inspection, and control calibration checks. Water treatment specialists emphasize the importance of maintaining chemical balance in closed-loop systems to prevent mineral scaling - a condition responsible for up to 12% efficiency degradation in untreated systems.

Operational logs from commercial facilities reveal that strictly following manufacturer-recommended maintenance intervals extends equipment service life by approximately 38% compared to reactive repair approaches. Technicians utilize specialized tools for flue gas analysis and thermal imaging to identify developing issues before they impact production. Most reputable suppliers offer comprehensive service agreements including bi-annual system optimization visits with detailed performance reporting.

Partnering with Established Water Boiler for Greenhouse Factory Experts

Selecting a manufacturing partner with documented industry expertise delivers measurable operational advantages. Commercial growers should prioritize water boiler for greenhouse factories possessing ISO 9001 certification with verifiable installations in comparable agricultural operations. Technical assessment teams evaluate multiple criteria including thermal load calculations, pipe distribution schematics, combustion air requirements, and fuel storage infrastructure.

Reputable manufacturers provide comprehensive support from conceptual design through operational commissioning including staff training programs. Evidence from procurement departments indicates growers who partner with established suppliers benefit from 27% faster installation timelines and receive 45% more favorable financing terms through manufacturer-backed lending programs. These established technical relationships ultimately translate into higher system reliability and production consistency throughout equipment service life.

(water boiler for greenhouse)

FAQS on water boiler for greenhouse

Q: What is a water boiler for greenhouse?

A: It is a specialized heating system designed to warm greenhouses efficiently. By circulating hot water, it ensures consistent temperatures for optimal plant growth. This supports agricultural productivity in various climates.

Q: How to choose a reliable water boiler for greenhouse supplier?

A: Evaluate suppliers based on industry expertise and positive customer feedback. Verify their certifications, such as ISO standards, for quality assurance. Prioritize those offering technical support and warranty services.

Q: What key features should a water boiler for greenhouse product have?

A: Look for energy efficiency with low emissions and automatic temperature controls. Durable materials ensure longevity in humid greenhouse environments. User-friendly installation and maintenance options enhance usability.

Q: What standards do water boiler for greenhouse factories follow?

A: Reputable factories adhere to international guidelines like ISO 9001 for manufacturing. They implement rigorous testing for safety and performance. Sustainable practices and advanced automation also ensure high-quality outputs.

Q: Why is a water boiler beneficial for greenhouse operations?

A: It provides uniform heat distribution to prevent frost damage to crops. Energy-saving designs lower greenhouse running costs. Overall, it boosts yield and supports year-round cultivation.

-

Top Electric Steam Boiler Manufacturers | Industrial Steam SolutionsNewsJul.26,2025

-

Top Electric Steam Boiler Manufacturers – Reliable Industrial SolutionsNewsJul.25,2025

-

Top Electric Steam Boiler Manufacturers – Reliable Industrial SolutionsNewsJul.24,2025

-

Top Electric Steam Boiler Manufacturers – High Efficiency & ReliabilityNewsJul.23,2025

-

Best China Steam Boiler Price for Efficient Industrial HeatingNewsJul.22,2025

-

Top Electric Steam Boiler Manufacturers - High-EfficiencyNewsJul.21,2025