Proper Installation of Steam Boilers for CE Certification Compliance and Safety Standards

CE Certification for Well-Installed Steam Boilers

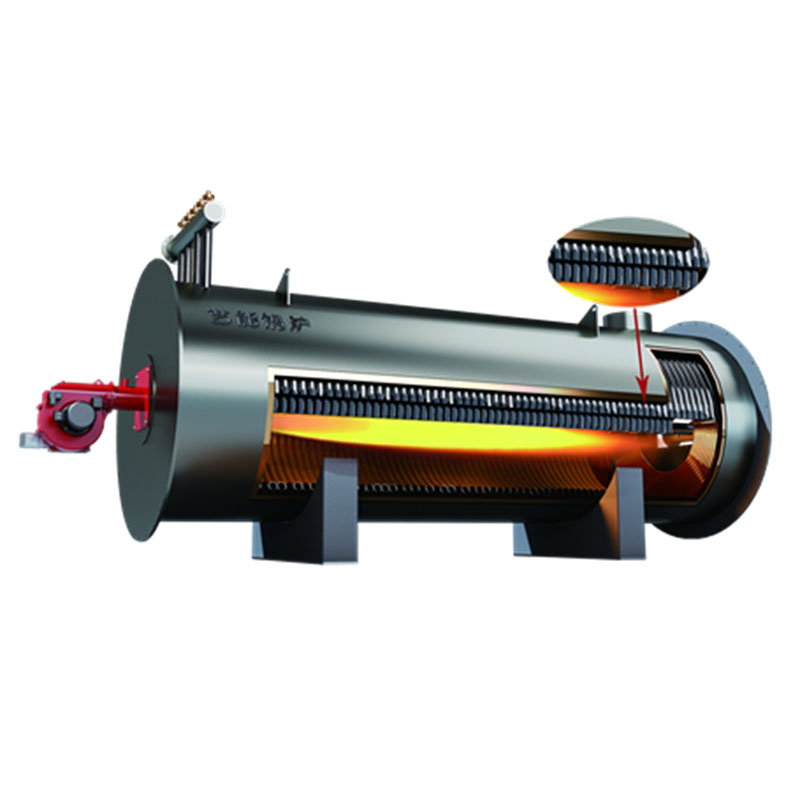

In today’s industrial landscape, steam boilers play a crucial role in various processes, including power generation, heating, and manufacturing. As the demand for efficient and safe steam production grows, so does the importance of adhering to stringent safety and quality standards. One of the most significant certifications that ensure these standards are met is the CE certification.

The CE marking indicates that a product complies with European Union (EU) safety, health, and environmental protection standards. For steam boilers, obtaining CE certification is essential not only for legal marketing within Europe but also for fostering consumer confidence. It demonstrates that the boiler is designed and manufactured to meet the applicable EU directives and regulations.

Importance of Proper Installation

While acquiring CE certification is critical, it is equally essential to ensure that steam boilers are installed correctly. A well-installed boiler can optimize performance, enhance safety, and extend the equipment's lifespan. Poor installation, on the other hand, can lead to malfunctions, increased energy costs, and even hazardous accidents.

The installation process should comply with the manufacturer's guidelines and national regulations. A certified professional should carry out the installation, ensuring that all components are correctly assembled, connections are secure, and safety devices are operational. Proper installation not only enhances efficiency but also ensures that the boiler maintains its CE certification status.

Steps to Obtain CE Certification

To achieve CE certification for a steam boiler, manufacturers must follow a structured process that involves several key steps

1. Identify Applicable Directives Manufacturers should determine which EU directives apply to their product. For steam boilers, relevant directives include the Pressure Equipment Directive (PED) and the Machinery Directive.

ce certification well installed steam boiler

2. Product Testing The boiler must undergo rigorous testing to ensure it meets safety and performance standards. This testing may include inspections of materials, assembly processes, and operational capabilities.

3. Technical Documentation Comprehensive technical documentation must be compiled, showcasing the boiler’s design, manufacturing process, and testing methods. This documentation is vital for regulatory compliance and for any future inspections.

4. Quality Assurance Implementing a quality assurance system ensures that the manufacturing process consistently meets the required standards. This may involve regular audits, employee training, and continuous process improvement.

5. Affixing the CE Mark Once all requirements are met, the manufacturer can affix the CE mark to the boiler, indicating compliance. This marking should be accompanied by a Declaration of Conformity, which outlines the product's adherence to relevant EU directives.

Ongoing Compliance and Inspection

Achieving CE certification is not the end of the process. Manufacturers and operators must ensure ongoing compliance through regular inspections and maintenance. Routine checks are essential to verify that the boiler continues to operate safely and efficiently, thus minimizing the risk of failure or accidents.

Operators of steam boilers are also responsible for training personnel on safe operation and maintenance practices. Ensuring that staff are knowledgeable about the equipment and its requirements promotes a culture of safety and efficiency within the organization.

Conclusion

In conclusion, CE certification for steam boilers is a vital aspect of ensuring safety and performance standards in industrial applications. However, certification alone is not enough; proper installation and ongoing compliance are essential to maximize the benefits of steam boilers. By prioritizing these factors, manufacturers and operators can contribute to a safer work environment and achieve greater operational efficiency.

-

Efficient Thermal Oil Boilers with AI Optimization | Superior PerformanceNewsAug.03,2025

-

High-Efficiency OEM Steam Boilers w/GPT-4-TurboNewsAug.02,2025

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025