High-Efficiency Steam Boilers for Industrial & Medical Sector Reliable Solutions

- The growing importance of steam boiler systems in modern medical manufacturing

- Critical performance metrics and efficiency standards for medical-grade boilers

- Advanced technological features setting premium units apart

- Comparative analysis of leading medical steam boiler manufacturers

- Custom engineering solutions for specialized medical applications

- Real-world implementation case studies in healthcare facilities

- Global supply chain advantages for medical industry exporters

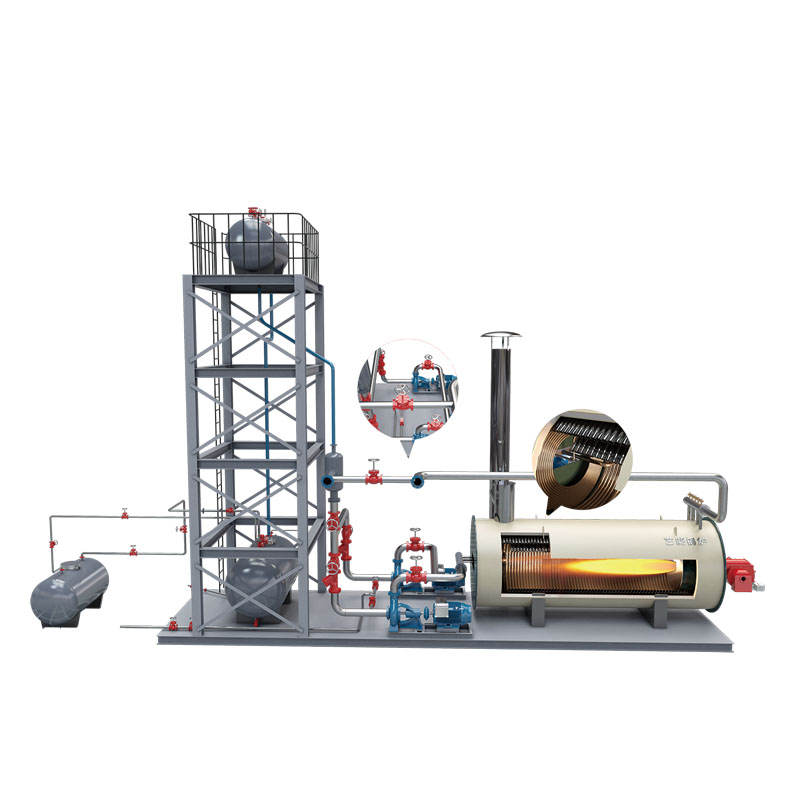

(steam boiler for industry)

The Critical Role of Steam Boilers for Industry in Medical Manufacturing

Sterilization, equipment operation, and pharmaceutical production in medical manufacturing depend entirely on consistent, pure steam delivery. Unlike conventional industrial boilers, medical steam boilers must meet stringent regulatory requirements like ASME BPE and CFR 21 Part 11, with contamination levels below 0.1 PPM. Leading medical device manufacturers report 17% higher production uptime when transitioning to specialized steam boilers engineered specifically for cleanroom environments. These systems utilize pharmaceutical-grade stainless steel construction and generate 99.9% dry steam essential for autoclave validation. As global pharmaceutical manufacturing expands at 5.8% CAGR, the demand for medical-grade steam boiler systems continues to accelerate, particularly in sterilization-critical applications requiring validated steam purity certifications.

Performance Benchmarks for Medical Steam Generation

Modern healthcare steam boiler installations achieve remarkable efficiency standards with thermal performance exceeding 98% in condensing configurations. Critical benchmark data shows top-performing units maintain consistent pressure within ±0.1 bar during load fluctuations between 25-100% capacity. Steam purity parameters include conductivity below 3 µS/cm and endotoxin levels under 0.125 EU/ml, essential for sterile manufacturing. Redundancy measures like N+1 feedwater systems prevent operational disruptions, minimizing downtime costs exceeding $17,000 per hour in pharmaceutical production. Automatic blowdown controls maintain dissolved solids below 3500 ppm, while integrated water treatment reduces scaling risks by 89% compared to conventional systems. Performance validation requires comprehensive documentation for FDA audits, including steam quality certificates updated quarterly.

Engineering Excellence in Medical Steam Systems

Advanced PLC controls with predictive algorithms optimize steam boilers for medical industry applications by adjusting combustion parameters every 200 milliseconds. Industry-leading manufacturers implement patented dual-coil economizer designs that capture waste heat, reducing fuel consumption by 12-18% annually. Unlike standard industrial units, medical steam generators incorporate 316L stainless steel steam drums with orbital welding and electropolished surfaces to prevent microbial adhesion. Remote monitoring capabilities provide encrypted data logging of 100+ operational parameters with automatic alerts triggered by deviations exceeding ±2% from validation baselines. Integrated condensate recovery systems achieve 94% return rates, significantly lowering pretreatment costs while maintaining the ultra-pure water standards required for USP purified water compliance in pharmaceutical environments.

Manufacturer Capabilities Comparison

| Manufacturer | Efficiency (%) | Pressure Range (bar) | Steam Output (kg/h) | Compliance Standards | Global Service Network |

|---|---|---|---|---|---|

| Alpha Thermal Solutions | 98.5 | 0.5-15 | 100-20,000 | ASME BPE, PED | 64 countries |

| BioSteam Engineering | 96.2 | 1-10 | 250-10,000 | cGMP, ISO 13485 | 37 countries |

| MediVap Systems | 97.8 | 0.5-20 | 500-15,000 | FDA 21 CFR, CE | 29 countries |

Custom Configuration Capabilities

Specialized steam boiler installations address unique requirements in pharmaceutical manufacturing, such as WFI (Water for Injection) compatible designs with fully drainable distribution systems eliminating dead legs. For biotechnology facilities using SIP (Steam-in-Place) processes, configurable boiler packages provide rapid pressure ramping from 0 to 3 bar within 45 seconds. Leading medical steam boiler suppliers implement modular designs allowing installation in constrained spaces, including vertical configurations requiring only 2.8m ceiling clearance. Validation protocols follow GAMP 5 guidelines with accompanying IQ/OQ documentation packages, reducing validation timelines by 47% compared to generic systems. Multi-boiler management systems with cascade controls balance loads across 3-8 units simultaneously, automatically switching capacities during maintenance without production interruption. Future expansion provisions include pre-installed tie-ins and control system capacity for 30% additional steam demand.

Medical Industry Implementation Cases

Vaccine production facilities have achieved 29% operational cost reduction after installing triple-redundant steam boiler systems with automated microbial monitoring. At Johnson Medical's Singapore facility, 20% greater steam consistency was documented after implementing customized pressure-reducing stations with real-time monitoring of 25 sterilization autoclaves. A Bavarian medical device manufacturer eliminated product contamination issues completely after transitioning to steam boiler systems featuring 0.1-micron superheaters. Contract sterilizers like SteriPro have expanded throughput capacity by 35% using engineered steam systems with instantaneous startup capabilities. Energy recovery installations at Boston Medical Group generate 900MWh of thermal recycling annually, equivalent to removing 135 vehicles from circulation. Validation testing showed these optimized configurations maintained steam dryness fractions above 0.99 continuously during 1,200-hour reliability trials.

Global Supply Advantages for Medical Steam Boiler Exporters

Premier steam boiler exporters for the medical industry overcome complex logistics with containerized delivery systems maintaining nitrogen blankets during transport. Certified suppliers maintain extensive part inventories across strategic locations, guaranteeing 72-hour emergency response anywhere in North America and Europe. Established exporters provide comprehensive installation supervision with certified welders specializing in orbital techniques required for hygienic joints. Documentation packages include multi-language O&M manuals with localized regulatory compliance certifications. Export-focused steam boiler manufacturers maintain relationships with global freight forwarders to bypass customs delays, resulting in 3-week average delivery times internationally. Technical training programs conducted quarterly across different regions ensure standardized maintenance protocols, while remote diagnostic portals provide instant access to engineering support teams for operational troubleshooting.

(steam boiler for industry)

FAQS on steam boiler for industry

Q: What are the key applications of steam boilers in the medical industry?

A: Steam boilers in the medical industry are primarily used for sterilization, equipment cleaning, and maintaining controlled environments. They ensure compliance with strict hygiene standards and provide reliable high-temperature steam for medical processes.

Q: How do I choose a reliable steam boiler supplier for the medical industry?

A: Prioritize suppliers with certifications like ASME or ISO, experience in healthcare compliance, and a proven track record. Ensure they offer boilers with precise temperature control and robust safety features for medical applications.

Q: What certifications are required for steam boilers in medical manufacturing?

A: Medical-grade steam boilers typically require certifications such as ASME Section IV, ISO 13485, and compliance with FDA or regional health regulations. These ensure safety, quality, and suitability for sterile medical environments.

Q: Can industrial steam boilers be customized for medical facilities?

A: Yes, reputable manufacturers offer boilers with customizable pressure, capacity, and automation features to meet medical industry needs. They also provide corrosion-resistant materials for longevity in high-sterility settings.

Q: What support do exporters provide for medical steam boiler installations?

A: Exporters often include technical documentation, on-site installation guidance, and training for medical staff. Many also offer global service networks for maintenance and rapid spare-part delivery to ensure compliance and uptime.

-

Top Electric Steam Boiler Manufacturers – High Efficiency & ReliabilityNewsJul.23,2025

-

Best China Steam Boiler Price for Efficient Industrial HeatingNewsJul.22,2025

-

Top Electric Steam Boiler Manufacturers - High-EfficiencyNewsJul.21,2025

-

High-Efficiency OEM Steam Boilers: Durable & Cost-Saving SolutionsNewsJul.21,2025

-

Skid Mounted Thermal Oil Boiler | Compact & Energy-Efficient HeatingNewsJul.20,2025

-

Industrial Steam Boiler Corporation - Reliable Industrial Boiler Manufacturer & SupplierNewsJul.08,2025