OEM Design for Efficient Reciprocating Grate Boiler Solutions and Applications

Understanding OEM Reciprocating Grate Boilers

Reciprocating grate boilers are a significant component in the manufacturing and energy sectors, particularly when it comes to solid fuel combustion. These boilers are designed to efficiently convert a variety of biomass and waste materials into energy, making them an essential aspect of sustainable energy production. The term OEM, or Original Equipment Manufacturer, refers to companies that produce these boilers, ensuring they meet specific industry standards and customer requirements.

Working Principle of Reciprocating Grate Boilers

The functioning of a reciprocating grate boiler is based on a mechanical grate system that helps in the controlled movement of fuel. The fuel is fed into the boiler's combustion chamber where it is combusted. The reciprocating grate consists of numerous moving parts that allow for a layered bed of fuel to be maintained. This design is particularly effective for materials that do not ignite uniformly, such as wood chips, agricultural waste, and industrial by-products.

As the grate moves, it pushes unburned fuel towards the back of the chamber while allowing completely burned ash to fall through the front. This process not only helps in achieving efficient combustion but also minimizes the need for manual clean-up, thus enhancing operational efficiency.

Advantages of Reciprocating Grate Boilers

1. Versatility in Fuel Types One of the primary advantages of reciprocating grate boilers is their ability to burn different forms of solid fuels. This includes wood, agricultural residues, and even municipal solid waste. This flexibility allows industries to utilize local waste streams as fuel sources, promoting sustainability and energy independence.

2. High Efficiency Compared to traditional combustion systems, reciprocating grate boilers can achieve higher efficiencies. Their design allows for better heat transfer and combustion control, which can lead to lower emissions and reduced fuel consumption.

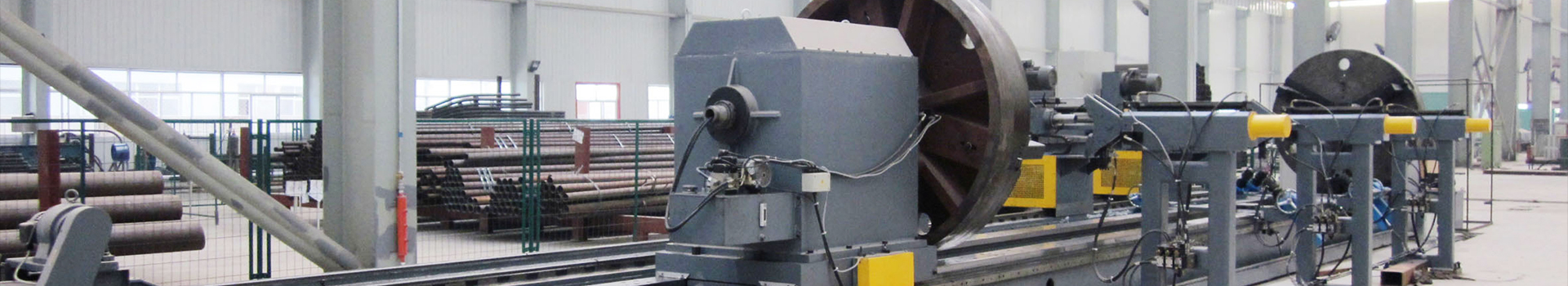

oem reciprocating grate boiler

3. Lower Emissions Advanced designs in OEM reciprocating grate boilers include features that enhance combustion efficiency and reduce harmful emissions. Technologies such as flue gas recirculation and optimized air supply help ensure thorough combustion while minimizing pollutants like CO2, NOx, and particulate matter.

4. Reduced Maintenance Needs The automatic ash removal system inherent in reciprocating grate boilers significantly cuts down on maintenance time. Operators can focus on running the boiler rather than spending excessive time on manual ash clearing and equipment cleaning.

Applications

OEM reciprocating grate boilers are widely used in various industries, including

- Power Generation Many utility companies harness biomass energy through these boilers, contributing to a greener energy grid. - Pulp and Paper The pulp and paper industry often utilizes waste wood and process residues, turning them into energy via reciprocating grate boilers. - Food Processing Manufacturers in the food sector use these boilers for steam generation and process heat, again leveraging waste materials as fuel.

Conclusion

The role of OEM reciprocating grate boilers in modern industries cannot be overstated. Their efficiency, versatility, and emission-reducing capabilities make them a vital component in the pursuit of sustainable energy solutions. As manufacturers continue to innovate, the potential for these boilers will only grow, enhancing their appeal in an increasingly eco-conscious market. By incorporating reciprocating grate boilers, industries not only power their processes but also contribute positively to environmental preservation.

In summary, as we face the dual challenges of energy demands and climate change, reciprocating grate boilers stand out as a pragmatic choice for renewable energy use, demonstrating that innovative engineering can help bridge the gap between economic growth and environmental stewardship.

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025