Leading Manufacturers of Automatic Feeding Boiler Systems for Various Applications

Automatic Feeding Boiler Manufacturers A Comprehensive Overview

Boilers play a crucial role in various industries, providing essential steam and heat for processes ranging from power generation to food processing. Among the diverse types of boilers available, automatic feeding boilers are becoming increasingly popular due to their efficiency and ease of operation. This article explores the landscape of automatic feeding boiler manufacturers, discussing their features, advantages, and the factors influencing their choice in industrial applications.

Automatic feeding boilers are designed to feed fuel into the combustion chamber automatically, significantly reducing the manual labor associated with traditional boiler types. These boilers can utilize various fuels, including coal, biomass, and pellets, making them versatile options for many sectors. The automated feeding mechanism ensures a consistent and controlled supply of fuel, which optimizes combustion performance and enhances energy efficiency.

Key Features of Automatic Feeding Boilers

1. Fuel Efficiency Automatic feeding boilers are engineered for maximum fuel efficiency. By utilizing sophisticated control systems, they can adjust the fuel feed rate according to the operational demand, ensuring optimal combustion throughout their operation.

2. Automation The integral automation in these boilers reduces the need for manual intervention, leading to lower labor costs and minimal human error. Operators can set parameters and monitor operations remotely, which enhances safety and reliability.

3. Temperature Control Advanced sensors and control systems allow for precise temperature regulation within the boiler system. This ensures that processes requiring specific thermal conditions can be maintained effectively.

4. Environmental Considerations Many manufacturers focus on eco-friendly designs that minimize emissions and maximize energy recovery. By improving combustion efficiency, automatic feeding boilers can significantly reduce harmful gas emissions, aligning with international standards for environmental protection.

Major Manufacturers of Automatic Feeding Boilers

The market for automatic feeding boilers features several prominent manufacturers, known for their innovation and quality. A few notable names include

1. Bosch Thermotechnology Known for its commitment to innovation, Bosch offers a range of automatic feeding boilers designed for various industrial applications. Their products are characterized by high efficiency and are equipped with state-of-the-art control systems.

2. Fulton Fulton has been a key player in the boiler manufacturing industry for over 60 years. Their automatic feeding boilers are famous for reliability and ease of maintenance, providing tailored solutions that meet specific customer needs.

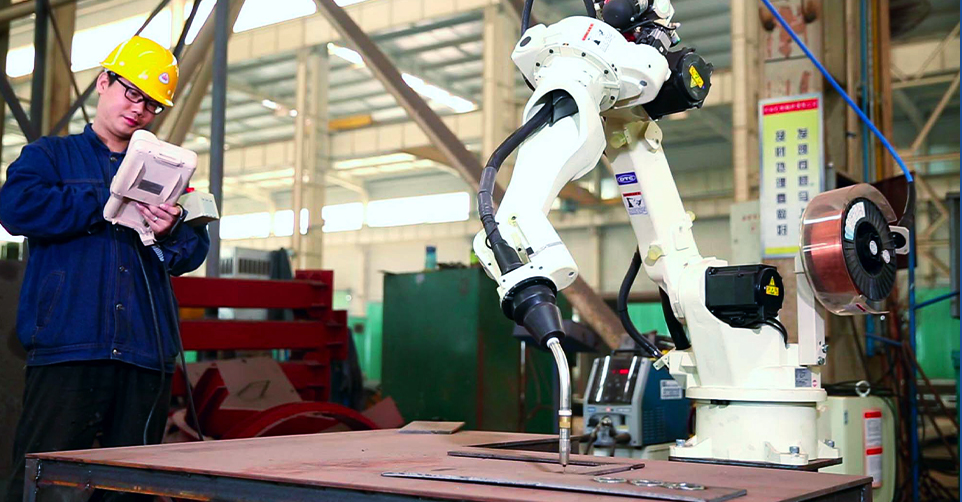

automatic feeding boiler manufacturers

3. Babcock & Wilcox This company has a longstanding reputation for its commitment to engineering excellence. They manufacture automatic feeding boilers that cater to different industry requirements, including large-scale energy generation.

4. Weil-McLain Known for its residential and commercial boilers, Weil-McLain also produces industrial-grade automatic feeding boilers. Their focus on customer support and innovative designs makes them a trusted choice in the marketplace.

Factors Influencing the Choice of Automatic Feeding Boilers

When industries consider investing in automatic feeding boilers, several factors come into play

1. Cost The initial purchase price, installation costs, and long-term operational expenses are critical factors. Businesses must evaluate the total cost of ownership against potential savings generated from higher efficiencies.

2. Energy Source The availability and cost of different fuel types can influence the choice of boiler. Some industries may prefer biomass for sustainability, while others might opt for coal or natural gas.

3. Space Requirements Automatic feeding boilers come in various sizes, so the available space for installation can play a significant role in the decision-making process.

4. Industry Regulations Compliance with local and international regulations regarding emissions and energy efficiency can significantly impact the choice of boiler. Manufacturers that prioritize environmentally friendly solutions are often favored.

5. After-Sales Support Reliable maintenance and support services are essential for ensuring the longevity and performance of the boiler. Businesses often favor manufacturers that provide comprehensive service packages.

Conclusion

As industries continue to seek ways to enhance efficiency and reduce operational costs, automatic feeding boilers offered by reputable manufacturers stand out as viable solutions. With their high fuel efficiency, automation features, and environmental benefits, these boilers are paving the way for a more sustainable and economically viable future in industrial thermal energy. As the market grows and technology evolves, companies can expect even more advanced options tailored to their specific needs.

-

Coal Fired Thermal Oil Heater Supplier Efficient & Durable Industrial Heating SolutionsNewsMay.18,2025

-

Organic Heating Transfer Material Boiler Supplier & Factory High-EfficiencyNewsMay.18,2025

-

Skid Mounted Thermal Oil Boilers Efficient & Compact Design ExporterNewsMay.17,2025

-

Bangkok Industrial Boiler Supplier High-Efficiency Solutions & Factory DirectNewsMay.17,2025

-

Best Home Heating Hot Water Boiler Reliable Exporter & Affordable PricesNewsMay.17,2025

-

High Efficiency Residential Steam Boilers Energy-Saving & ReliableNewsMay.16,2025