What are Molten Salts?

What are Molten Salts?

Molten salts are a phase change material used to store thermal energy.

Phase change materials are solid at room temperature and atmospheric pressure and turn into fluids when heated.

Molten salts store the energy applied to convert them into liquids as latent heat, which they can transfer to other materials. The heat transfer, therefore, occurs in two directions. When heat is applied, the salts melt. When the heat is removed, the liquid solidifies again.

As phase change materials, molten salts have a higher latent heat capacity than conventional materials, and minimal temperature changes are needed to increase their heat capacity.

Benefits of Molten Salts

The most common benefit of all molten salts is their thermal stability at high temperatures.

Molten salts make a good heat storage and transfer medium because they have low viscosity, high thermal and electrical conductivity, and good chemical and thermal stability.

Since they have a low vapour pressure, they’re also suitable for heat transfer where people want to avoid pressure buildup and reduce the need to use heavy piping. Furthermore, molten salts are chemically stable, are better for the environment, and pose no major safety risks. They are also non-toxic when spilled in small quantities.

Additionally, molten salts do have other safety and economic advantages, including fewer critical plant accidents, no large volumes of steam containing radionuclides (an unstable form of a chemical element that releases radiation as it breaks down), and cost-savings from higher thermal efficiency (when compared to other coolants).

Challenges and Considerations of Molten Salts

Many molten salts are corrosive; among them, nitrates are the least corrosive. Corroded metals will ultimately cause equipment to crack, weaken, and fail.

Furthermore, molten salts freeze at the solidification temperature, higher than atmospheric temperatures. For the standard molten salt mixture of sodium nitrate and potassium nitrate, this temperature is as high as 220°C to 240°C.

Freezing occurs due to the development of cold spots because of uneven heating or on winter evenings. The resultant salt expansion damages large vessels, piping, and equipment.

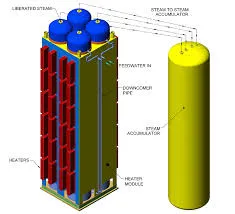

Waste heat recovery boiler

Advancements in Molten Salt technology

Therefore, continued advancements in molten salt technology are partitive. Companies like Contec are already investing time and resources into Research and Development (R&D) to expand this topic.

Emerging technology applications with molten salts need more detailed research and investment. The pyrolysis process at Contec is rooted in R&D, where the Molten® technology was incorporated into the tire pyrolysis during laboratory testing. Molten salts were found to improve the efficiency and safety of tire pyrolysis, as well as, for the health and safety of plant operators and the environment.

Our technology is unique because we use a commercially available salt mixture called Molten® as a heating agent in our customised pyrolysis technology. Contec’s pyrolysis process is the first to operate its heat reactors with the molten salt medium. Molten®, combined with rotating augers, ensures that Contec can heat all the rubber granules from end-of-life tires (ELTs) evenly for an optimum duration to produce high-quality Recovered Carbon Black (rCB).

– Klaudia Końska, Junior R&D Manager at Contec

Advancements in molten salt technologies are just beginning. Tire pyrolysis is just one system application that yields the huge potential to help decarbonise the manufacturing industry.

What are molten salts used for?

As molten salts remain liquid at 250°C to 1000°C and have a low vapour pressure, the property makes them suitable for applications where liquids at very high temperatures are necessary for heat storage or transfer.

Molten salts heated beyond their liquid temperature range degrade into gaseous components. Combining different salts can lower the melting points of the salts and increase the temperature range where they remain as liquids. Depending on the temperatures required and the applications, different mixtures of salts can be used.

The common molten salts used as a heat transfer medium are a mixture of two salts — 60 per cent sodium nitrate and 40 per cent potassium nitrate, which melt when heated at 220°C. They remain as liquids in the temperature range of 220°C to 600°C and decompose into nitrogen and nitrogen oxides at temperatures over 600°C.

Molten salts over other heat transfer mediums

Water and synthetic oils are also common fluids currently used as heat transfer mediums.

Considering all these selection criteria, molten salts can replace water and synthetic oils as heat transfer mediums.

- Water is widely used for heat transfer because it has high thermal conductivity, density, latent energy, and moderate viscosity. But water can only transfer heat at temperatures less than 100°C because it produces high vapour pressure at its boiling point.

- Synthetic or thermal oils remain as liquids up to 300°C. While these are high temperatures, it is not enough for the process heating of materials like waste tires. Moreover, the oils have low density and chemical stability; they are also flammable and can cause high-pressure buildup, a safety risk.

Common Molten Salt Uses

Molten salts have many applications, including in nuclear systems, storing thermal energy for solar power plants, and chemical recycling.

As molten salts are composed of nitrates, nitrites, carbonates, chlorides, and fluorides, each of them has unique properties that make them useful for varying applications. They’re commonly used as an engineering fluid for high-temperature energy storage and heat transfer applications.

These are the most common molten salt uses:

- Storing thermal energy in solar power plants: The most widespread use of molten salts is to store thermal energy in solar power plants. During the day, the excess solar heat not used for making electricity is sent to molten salts for storage. Solar plants use the heat stored in molten salts to produce steam and generate electricity overnight. Molten salt systems can increase the capacity of solar plants from 25 per cent to 70 per cent.

- Nuclear systems: molten salts have been used as coolants and fuel solvents in fission and breeder reactors.

- Chemical recycling: Molten salts are used as heat transfer systems, for process heating of waste tires, and in pyrolysis for material recovery. Contec S.A. specialises in end-of-life tire processing through chemical recycling, transforming discarded tires into circular, sustainable raw materials. What sets Contec apart is its proprietary Molten® technology, which utilises molten salt as a heat transfer medium. This innovative approach ensures a safer, more efficient, and economically viable production.

- Steel processing: Molten salts are also commonly used for heating and quenching steel.

Common Types of Molten Salt Systems

The three common methods of using molten salts for heat transfer are salt baths, circulated molten salts, and direct heating.

- Salt baths: The molten salts are in an open vessel and heat transfer occurs through natural convection. Steel heating and quenching use this system, where objects to be heated, are in contact with the molten salt mass.

- Circulating molten salts: Molten salt systems are kept in circulation in a closed loop as a heat medium for process heating or heat exchange. First, the salts are melted in a salt tank with the help of electricity or fuel. Specially designed pumps keep the molten salts circulating in the loop and return them to the salt tank after the process is over or when the salts need reheating. Solar power plants and pyrolysis of waste tires use this method.

- Direct heating: Metal assemblies use molten salts for direct heating.

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.21,2025

-

Efficient Waste Heat Boilers: Energy Recovery SolutionsNewsAug.19,2025

-

Industrial Thermal Oil Boilers | Efficient & Reliable HeatingNewsAug.18,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable SolutionsNewsAug.17,2025

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.15,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.14,2025