Jun . 27, 2024 05:39

Back to list

Best Thermal Oil Circulating Boiler

Best Thermal Oil Circulating Boiler A Comprehensive Guide

Introduction

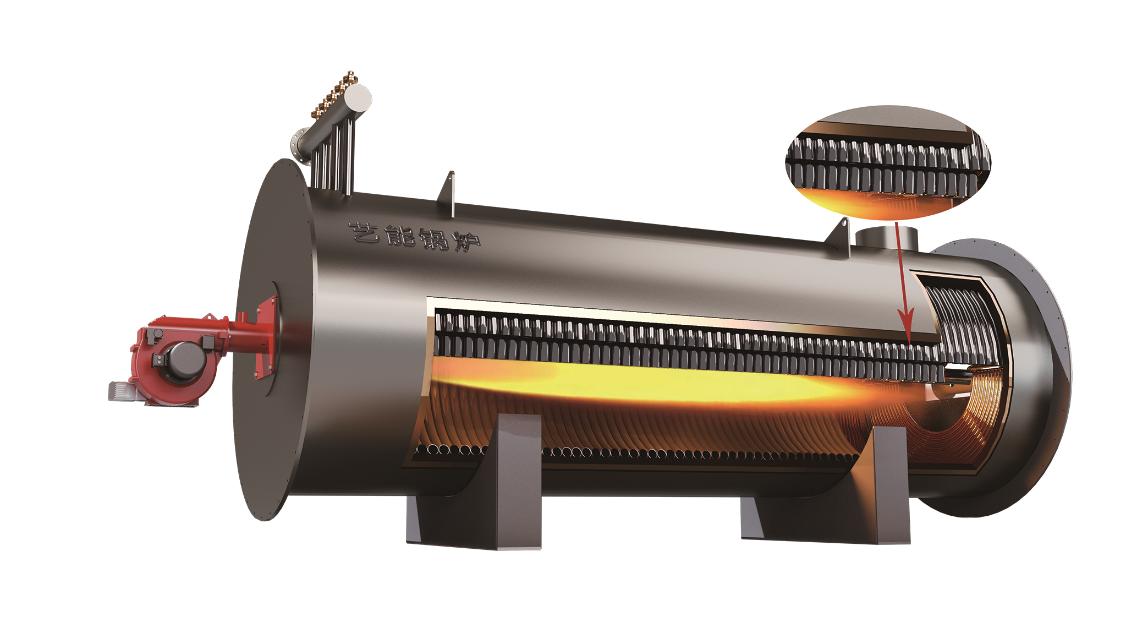

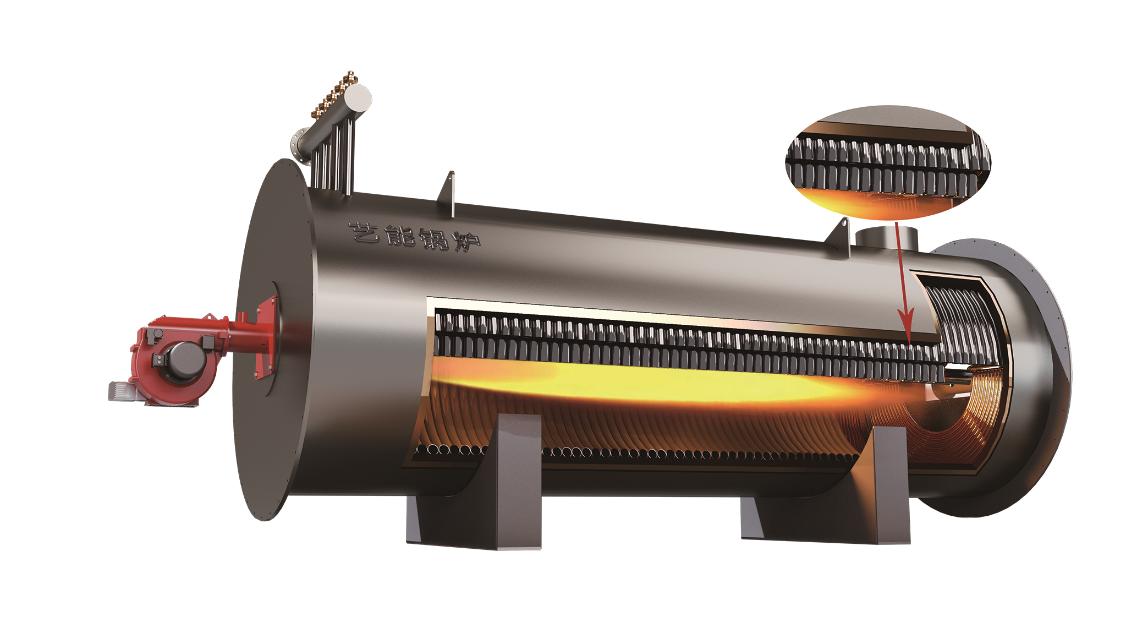

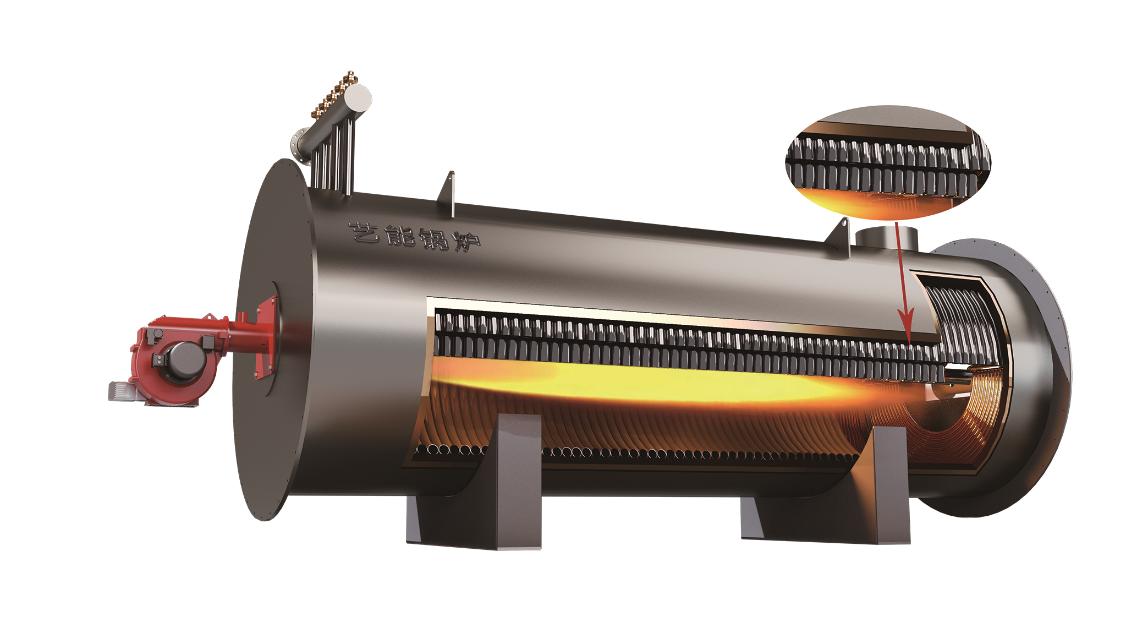

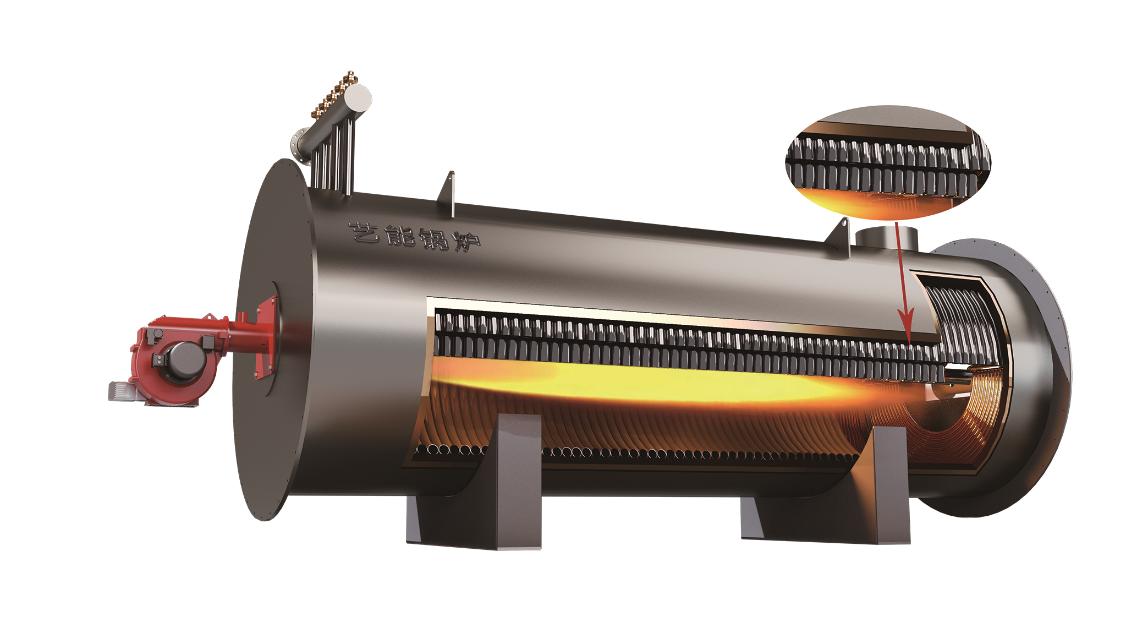

The best thermal oil circulating boiler is a crucial piece of equipment for industries that require efficient and reliable heating systems. These boilers use thermal oil as the heat transfer medium, providing uniform heat distribution and high thermal efficiency. In this article, we will discuss the key features to look for when selecting the best thermal oil circulating boiler for your specific needs.

Factors to Consider When Choosing the Best Thermal Oil Circulating Boiler

1. Capacity The capacity of the boiler should be chosen based on the heat requirements of your process. Boilers are available in various sizes, ranging from small units suitable for small-scale applications to large-scale units capable of meeting the demands of industrial processes.

2. Efficiency Look for a boiler with high thermal efficiency to minimize energy consumption and operating costs. Modern boilers are designed with advanced technologies such as condensing heat exchangers and modulating burners, which can significantly improve efficiency.

3. Fuel Type Thermal oil boilers can be powered by a variety of fuels, including natural gas, propane, oil, and biomass. Consider the availability and cost of the fuel source when choosing a boiler.

4. Temperature Control A good thermal oil circulating boiler should have accurate temperature control mechanisms to ensure stable and uniform heat distribution Temperature Control A good thermal oil circulating boiler should have accurate temperature control mechanisms to ensure stable and uniform heat distribution Temperature Control A good thermal oil circulating boiler should have accurate temperature control mechanisms to ensure stable and uniform heat distribution Temperature Control A good thermal oil circulating boiler should have accurate temperature control mechanisms to ensure stable and uniform heat distribution

Temperature Control A good thermal oil circulating boiler should have accurate temperature control mechanisms to ensure stable and uniform heat distribution Temperature Control A good thermal oil circulating boiler should have accurate temperature control mechanisms to ensure stable and uniform heat distribution best thermal oil circulating boiler. This is especially important for processes that require precise temperature control, such as chemical reactions and food processing.

5. Safety Features Safety is a critical consideration when selecting a thermal oil circulating boiler. Look for boilers with advanced safety features such as low-oil level protection, overheat protection, and flame failure protection.

6. Maintenance A boiler that requires frequent maintenance can be costly and disrupt production. Choose a boiler with easy access to components for cleaning and inspection, as well as a maintenance plan that includes regular inspections and tune-ups.

7. Brand Reputation Finally, consider the reputation of the manufacturer when choosing a thermal oil circulating boiler. Look for brands that have a track record of producing high-quality, reliable boilers and offer excellent customer support.

Conclusion

Selecting the best thermal oil circulating boiler for your needs involves considering several factors, including capacity, efficiency, fuel type, temperature control, safety features, maintenance requirements, and brand reputation. By carefully evaluating these factors and choosing a boiler that meets your specific requirements, you can ensure optimal performance, reduced energy costs, and improved safety in your industrial processes.

best thermal oil circulating boiler. This is especially important for processes that require precise temperature control, such as chemical reactions and food processing.

5. Safety Features Safety is a critical consideration when selecting a thermal oil circulating boiler. Look for boilers with advanced safety features such as low-oil level protection, overheat protection, and flame failure protection.

6. Maintenance A boiler that requires frequent maintenance can be costly and disrupt production. Choose a boiler with easy access to components for cleaning and inspection, as well as a maintenance plan that includes regular inspections and tune-ups.

7. Brand Reputation Finally, consider the reputation of the manufacturer when choosing a thermal oil circulating boiler. Look for brands that have a track record of producing high-quality, reliable boilers and offer excellent customer support.

Conclusion

Selecting the best thermal oil circulating boiler for your needs involves considering several factors, including capacity, efficiency, fuel type, temperature control, safety features, maintenance requirements, and brand reputation. By carefully evaluating these factors and choosing a boiler that meets your specific requirements, you can ensure optimal performance, reduced energy costs, and improved safety in your industrial processes.

Temperature Control A good thermal oil circulating boiler should have accurate temperature control mechanisms to ensure stable and uniform heat distribution Temperature Control A good thermal oil circulating boiler should have accurate temperature control mechanisms to ensure stable and uniform heat distribution

Temperature Control A good thermal oil circulating boiler should have accurate temperature control mechanisms to ensure stable and uniform heat distribution Temperature Control A good thermal oil circulating boiler should have accurate temperature control mechanisms to ensure stable and uniform heat distribution best thermal oil circulating boiler. This is especially important for processes that require precise temperature control, such as chemical reactions and food processing.

5. Safety Features Safety is a critical consideration when selecting a thermal oil circulating boiler. Look for boilers with advanced safety features such as low-oil level protection, overheat protection, and flame failure protection.

6. Maintenance A boiler that requires frequent maintenance can be costly and disrupt production. Choose a boiler with easy access to components for cleaning and inspection, as well as a maintenance plan that includes regular inspections and tune-ups.

7. Brand Reputation Finally, consider the reputation of the manufacturer when choosing a thermal oil circulating boiler. Look for brands that have a track record of producing high-quality, reliable boilers and offer excellent customer support.

Conclusion

Selecting the best thermal oil circulating boiler for your needs involves considering several factors, including capacity, efficiency, fuel type, temperature control, safety features, maintenance requirements, and brand reputation. By carefully evaluating these factors and choosing a boiler that meets your specific requirements, you can ensure optimal performance, reduced energy costs, and improved safety in your industrial processes.

best thermal oil circulating boiler. This is especially important for processes that require precise temperature control, such as chemical reactions and food processing.

5. Safety Features Safety is a critical consideration when selecting a thermal oil circulating boiler. Look for boilers with advanced safety features such as low-oil level protection, overheat protection, and flame failure protection.

6. Maintenance A boiler that requires frequent maintenance can be costly and disrupt production. Choose a boiler with easy access to components for cleaning and inspection, as well as a maintenance plan that includes regular inspections and tune-ups.

7. Brand Reputation Finally, consider the reputation of the manufacturer when choosing a thermal oil circulating boiler. Look for brands that have a track record of producing high-quality, reliable boilers and offer excellent customer support.

Conclusion

Selecting the best thermal oil circulating boiler for your needs involves considering several factors, including capacity, efficiency, fuel type, temperature control, safety features, maintenance requirements, and brand reputation. By carefully evaluating these factors and choosing a boiler that meets your specific requirements, you can ensure optimal performance, reduced energy costs, and improved safety in your industrial processes. Latest news

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025