best boiler for mdf production line

The Best Boiler for MDF Production Line

In the modern manufacturing landscape, Medium Density Fiberboard (MDF) production has become a cornerstone of furniture, cabinetry, and construction materials. As the demand for MDF increases, manufacturers are tasked with optimizing their production processes to ensure efficiency and sustainability. One pivotal element that can influence both aspects is the boiler system used in the MDF production line. In this article, we’ll delve into the best types of boilers suitable for MDF production, their benefits, and selection criteria.

Understanding the Role of Boilers in MDF Production

Boilers serve as vital components in the MDF production process. They generate steam, which is primarily used for drying fiber and facilitating pressing in the MDF manufacturing line. The efficiency and reliability of the boiler system directly affect the overall productivity, energy consumption, and emission levels of the MDF production facility. Thus, choosing the right boiler is crucial for any MDF manufacturer aiming for optimal performance and compliance with environmental standards.

Types of Boilers for MDF Production

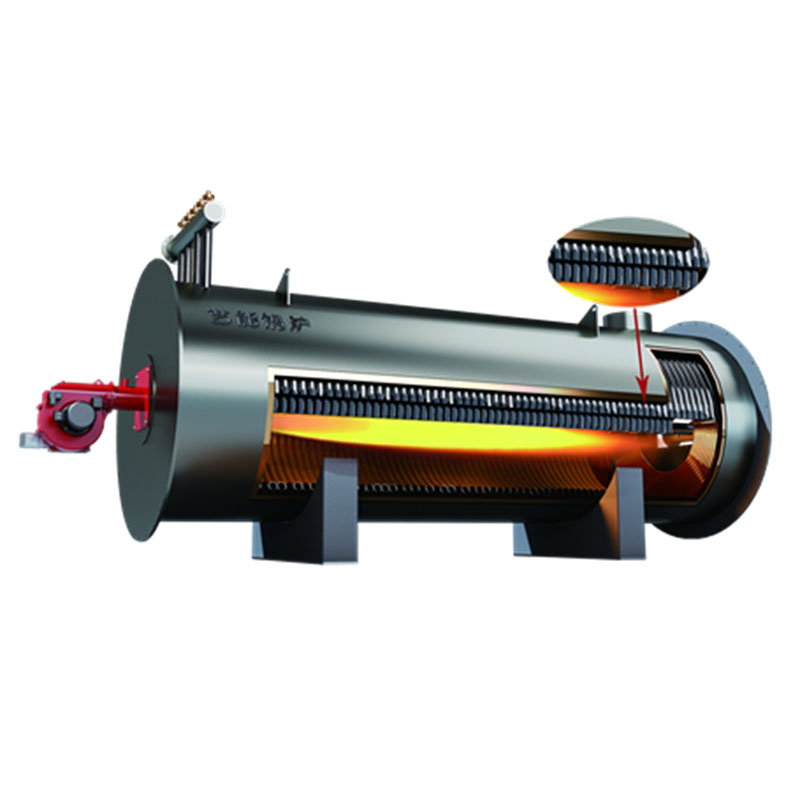

1. Water Tube Boilers These boilers are known for their high efficiency and ability to produce steam at high pressures. They are particularly well-suited for large-scale MDF production, as they can handle significant loads and provide a consistent supply of steam. The compact design also allows for easier integration into existing production lines.

2. Fire Tube Boilers Less efficient than water tube boilers, fire tube boilers are generally more cost-effective and easier to maintain. They are suitable for smaller MDF production facilities that may not require continuous high steam output. Their lower initial cost and simplicity can be appealing for startups or small-scale manufacturers.

3. Biomass Boilers An increasingly popular option, biomass boilers utilize renewable energy sources, such as wood waste and agricultural residues, which aligns perfectly with the sustainability goals of MDF production. These boilers not only provide an eco-friendly alternative to traditional fossil fuel energy but also help in managing waste generated during MDF production, making them a dual-purpose solution.

4. Modular Boilers For facilities looking to scale production, modular boilers provide flexibility. These systems can be added or removed based on production demand, ensuring that energy consumption aligns closely with operational needs. This adaptability can result in significant cost savings and enhanced efficiency.

best boiler for mdf production line

Key Considerations When Choosing a Boiler

When selecting the best boiler for MDF production, several factors should be taken into account

1. Energy Efficiency Look for boilers with high thermal efficiency ratings to minimize energy costs. Equipment that utilizes heat recovery systems can significantly improve overall efficiency.

2. Output Capacity Ensure that the boiler can meet the maximum steam demand of the production line without frequent cycling. This stability is crucial during peak production periods.

3. Sustainability Opt for systems that minimize emissions and utilize renewable energy sources. This commitment to environmental sustainability can enhance your brand’s reputation and comply with industry regulations.

4. Maintenance and Support Select a boiler with a reputation for reliability and ease of maintenance. Having a manufacturer that offers good after-sales support can also mitigate downtime and production losses.

5. Cost While initial costs are important, consider the total cost of ownership, including fuel costs, maintenance, and potential downtime. Making an informed choice here can lead to significant long-term savings.

Conclusion

The choice of the right boiler for an MDF production line has far-reaching implications for productivity, sustainability, and operational costs. As the MDF industry continues to evolve, investing in an efficient, reliable, and environmentally-friendly boiler system will be essential for manufacturers aiming to stay competitive. By considering the types of boilers available and carefully evaluating the specific needs of the production line, companies can enhance their operations and contribute to a sustainable manufacturing future.

-

High-Efficiency OEM Steam Boilers w/GPT-4-TurboNewsAug.02,2025

-

Advanced Electric Steam Boiler Manufacturers | GPT-4 Turbo AINewsAug.01,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025