best thermal oil circulating boiler

The Advantages of Best Thermal Oil Circulating Boilers

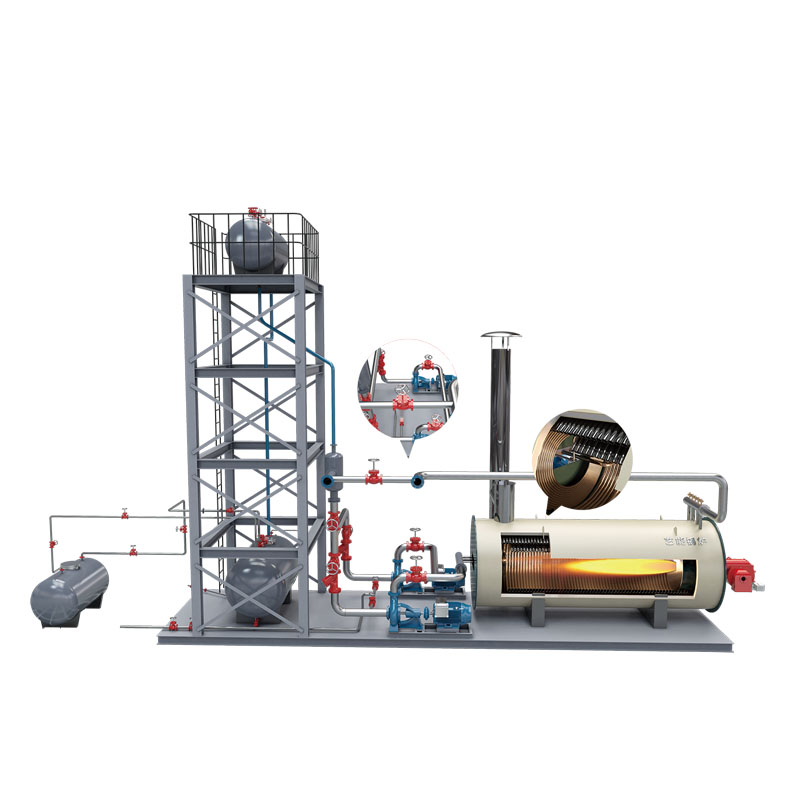

Thermal oil circulating boilers are becoming increasingly popular across various industries due to their unique ability to provide efficient heat transfer for high-temperature applications. Unlike conventional steam boilers that rely on water, thermal oil systems utilize organic fluids that can operate at much higher temperatures without the risks associated with high steam pressures. In this article, we will explore the advantages and benefits of the best thermal oil circulating boilers.

Efficient Heat Transfer

One of the primary advantages of thermal oil circulating boilers is their exceptional efficiency in heat transfer. Thermal oils can achieve operating temperatures of up to 400°C (752°F) or higher, making them ideal for industries such as food processing, chemical production, and oil extraction. The high thermal stability of these organic fluids allows for efficient energy use, which can lead to significant cost savings in energy consumption.

Flexibility in Design and Application

Thermal oil systems are known for their versatility. They can be designed to meet specific operational needs, allowing for customized solutions in various applications. For instance, thermal oil boilers can be integrated with heat exchangers, providing warmth and energy to multiple production lines or processes simultaneously. The ability to reach high temperatures without excessive pressure also means these systems are well-suited for a broad spectrum of industries, including textiles, plastics, pharmaceuticals, and even renewable energy production.

Safety Benefits

best thermal oil circulating boiler

Safety is another key advantage of thermal oil circulating boilers. Traditional steam systems operate under high pressures, posing risks of explosions or scalding injuries. In contrast, thermal oil systems operate at lower pressures, minimizing the risk associated with high-pressure steam. Additionally, the organic fluids used in thermal oil systems have higher flash points than water, which decreases the likelihood of fire hazards.

Reduced Maintenance Requirements

Thermal oil circulating boilers typically require less maintenance than traditional steam boilers. The absence of high-pressure steam reduces wear and tear on the system’s components, leading to extended operational life and lower maintenance costs. Moreover, thermal oils are less likely to cause corrosion compared to water systems, which can lead to costly repairs and downtime. Operators often find that thermal oil systems have a higher overall reliability, leading to uninterrupted production schedules.

Environmental Considerations

As industries strive to reduce their carbon footprint, thermal oil circulating boilers offer an eco-friendly alternative to traditional heating methods. Many thermal oils are designed to be non-toxic and environmentally safe, contributing to cleaner operations. Additionally, the efficiency of thermal oil systems translates to lower emissions, helping companies comply with increasingly stringent environmental regulations and standards.

Conclusion

In conclusion, the best thermal oil circulating boilers offer numerous advantages over traditional steam boilers, including superior heat transfer efficiency, design flexibility, improved safety, reduced maintenance needs, and environmental benefits. As industries continue to evolve and seek more effective and sustainable heating solutions, thermal oil systems represent a compelling option that meets both operational requirements and environmental responsibilities. Investing in a high-quality thermal oil circulating boiler can provide companies with a competitive edge by enhancing productivity, ensuring safety, and promoting sustainability. Businesses looking to upgrade their heating solutions should consider the substantial benefits that thermal oil circulating boilers can bring to their operations.

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025