biomass fired steam boiler pricelist

Understanding Biomass Fired Steam Boiler Pricing

In recent years, the demand for renewable energy sources has surged, prompting various industries to explore alternative fuels. Among these alternatives, biomass has become prominent due to its sustainability and environmental benefits. Biomass fired steam boilers play a crucial role in converting organic materials into usable energy, assisting industries in reducing their carbon footprints. This article delves into the factors affecting the pricing of biomass fired steam boilers and provides insights into their cost-effectiveness.

What is a Biomass Fired Steam Boiler?

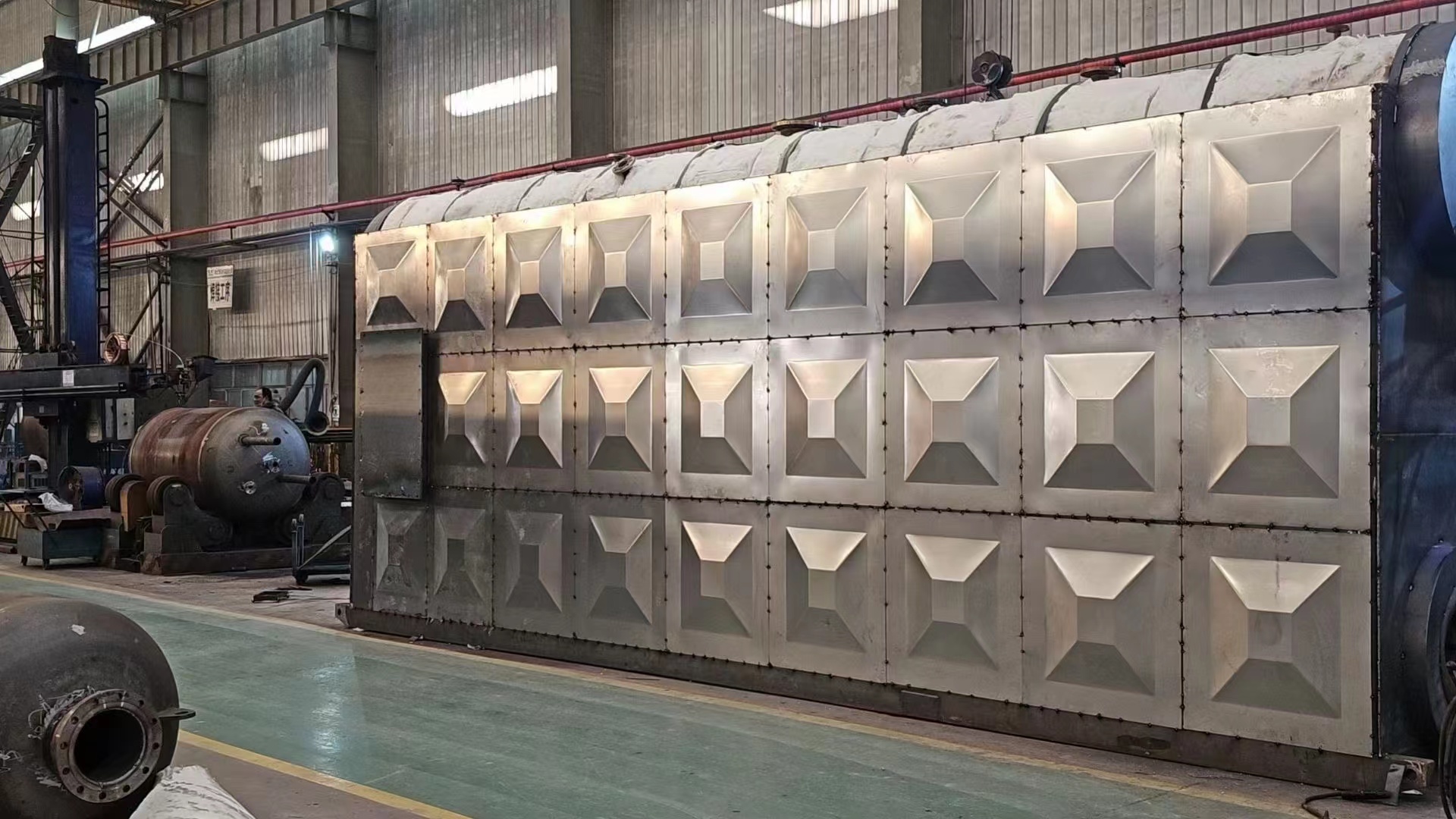

A biomass fired steam boiler is a type of boiler that generates steam by burning biomass materials. These materials can include wood chips, agricultural residues, and other organic matter. The combustion process converts the energy stored in biomass into heat, which is then used to generate steam for various applications, including power generation, heating, and industrial processes.

Factors Influencing Pricing

1. Type and Size of the Boiler The price of a biomass fired steam boiler can vary significantly based on its type and size. Larger and more sophisticated systems designed for high-capacity operations will generally cost more than smaller, simpler models. Industries must assess their specific steam requirements to determine the appropriate boiler size, which directly influences the cost.

2. Technology and Efficiency Advanced boiler technologies that enhance efficiency can come at a higher initial cost but lead to significant long-term savings. High-efficiency boilers reduce fuel consumption and operational costs by maximizing energy output. Technologies such as automatic fuel feeding systems, advanced emission control, and improved heat exchangers contribute to higher pricing.

3. Material Quality The materials used in boiler construction also affect prices. High-quality, durable materials can withstand higher temperatures and pressures, ensuring longer service life and lower maintenance costs. However, boilers constructed from premium materials will have higher upfront costs.

4. Local Regulations and Standards Compliance with local environmental regulations can influence boiler design and, subsequently, pricing. Manufacturers may invest in additional technology or modifications to meet stringent emission standards, which can elevate the overall cost. Buyers should consider these factors in relation to potential subsidies or incentives for using renewable energy sources.

biomass fired steam boiler pricelist

5. Installation Costs The installation process of biomass fired steam boilers can be complex and labor-intensive. Costs related to installation, including labor and necessary modifications to existing setups, can add significantly to the overall investment. Additionally, costs may vary based on location, accessibility, and the specific site requirements.

6. After-Sales Service and Maintenance The long-term performance of a biomass fired steam boiler is highly dependent on regular maintenance and support. Choosing a manufacturer or vendor that offers comprehensive after-sales service, spare parts availability, and professional maintenance will result in ongoing costs that must be considered in the overall price evaluation.

Price Ranges

The cost of biomass fired steam boilers can range widely based on the aforementioned factors. Generally, small to medium-sized models may start at around $50,000, while larger industrial systems can exceed $500,000 or more. Custom solutions tailored to specific operational needs will command premium prices, reflecting the unique design and engineering required.

Cost-Effectiveness and Return on Investment (ROI)

While the initial cost of biomass fired steam boilers may be higher than traditional fossil fuel systems, the long-term benefits often offset these initial expenses. Biomass is typically more cost-effective in areas where waste materials are abundant. Moreover, industries utilizing biomass can see significant savings on fuel costs while benefitting from potential tax incentives or subsidies.

The transition to biomass fired steam boilers aligns with global goals for sustainable energy, making them a valuable investment in the long run. Potential savings, coupled with the positive environmental impact, underline the importance of evaluating the total cost of ownership rather than focusing solely on initial purchase prices.

Conclusion

The pricing of biomass fired steam boilers is influenced by various factors, including size, technology, materials, installation, and ongoing maintenance. While the upfront costs may appear steep, the long-term benefits, including lower operational costs and positive environmental impacts, present a compelling case for industries to invest in these renewable energy solutions. As our society moves towards more sustainable energy sources, biomass fired steam boilers will continue to play an essential role in energy production and industrial applications.

-

Top Industrial Boiler Contractors Supplier & Factory Quality Products & ServicesNewsJun.10,2025

-

Panasonic Hot Water Boiler - Reliable & Energy Efficient Heating SolutionNewsJun.10,2025

-

Pennco Steam Boilers High-Efficiency & Durable SolutionsNewsJun.10,2025

-

Industrial Boiler & Mechanical Solutions Efficient Industrial Heating SystemsNewsJun.10,2025

-

Panasonic Hot Water Boiler - Energy-Efficient, Reliable Heat SolutionNewsJun.10,2025

-

Premium Power Plant Steam Boilers High Efficiency & ReliabilityNewsJun.09,2025