boiler for production factories

The Importance of Boilers in Production Factories

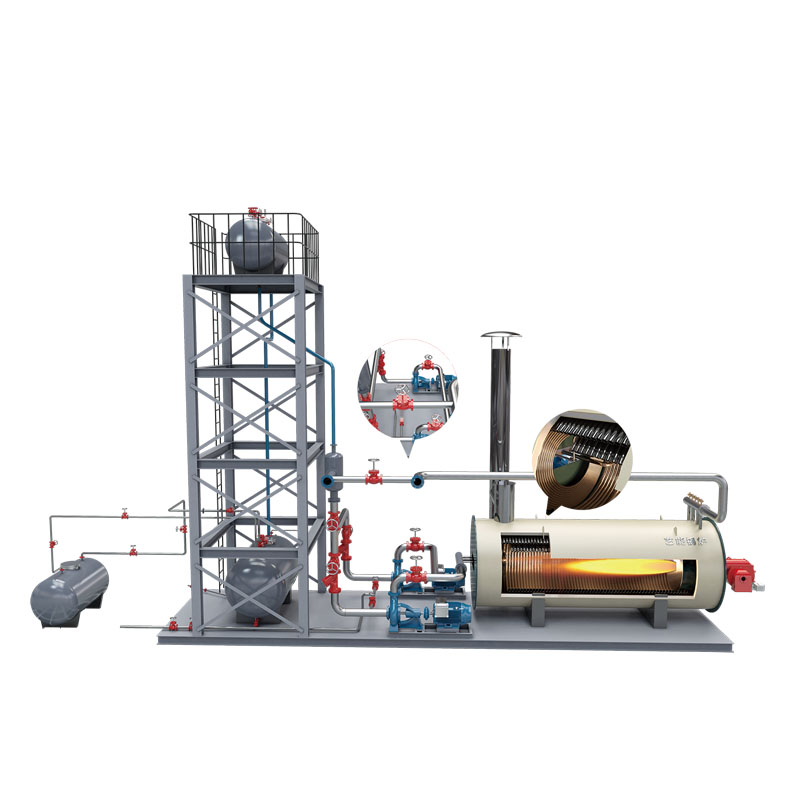

In the realm of industrial manufacturing, efficiency and reliability are paramount. Among the critical components that contribute to the seamless operation of production factories, boilers hold a significant place. These powerful devices not only produce steam and hot water but also provide energy solutions that are integral to various manufacturing processes. This article explores the role of boilers in production factories, their types, and the advancements that have made them more environmentally friendly and efficient.

Understanding Boilers

A boiler is a closed vessel that heats water or other fluid to generate steam or hot water for various applications. In production factories, steam is often utilized for heating, powering machines, and driving processes such as distillation, sterilization, and drying. The versatility of boilers makes them essential in industries ranging from chemical manufacturing to food processing.

Types of Boilers

There are several types of boilers used in production factories, each designed to meet specific needs

1. Fire-tube Boilers In these boilers, hot gases pass through tubes, which are surrounded by water. They are known for their simple design and ease of operation, making them suitable for smaller applications.

2. Water-tube Boilers Opposite to fire-tube boilers, water-tube boilers have water-filled tubes that are heated by gases from combustion. These systems are generally more efficient and can handle higher pressures, making them ideal for large-scale operations.

3. Electric Boilers Utilizing electricity to heat water, electric boilers are a clean and efficient alternative for certain applications. They are particularly useful in settings where gas supply is not feasible.

boiler for production factories

4. Biomass Boilers As sustainability becomes a critical concern in the manufacturing sector, biomass boilers are gaining popularity. These boilers use organic materials, such as wood, agricultural residues, and other biodegradable substances as fuel, reducing reliance on fossil fuels.

Efficiency and Sustainability

The modern factory is, in many ways, a testament to technological advancement, and boilers are no exception. Traditional boilers are being replaced by high-efficiency models that not only consume less fuel but also emit fewer pollutants. Features such as condensing economizers, which recover heat from flue gases, have become standard in new systems, significantly improving overall efficiency.

The push for sustainability in production has led to the development of more eco-friendly boiler options. Biomass and waste heat recovery boilers help companies reduce their carbon footprint while managing their energy needs. Transitioning to these technologies not only enhances a factory’s sustainability goals but can also lead to cost savings through lower fuel expenses and incentives for using green energy sources.

Maintenance and Reliability

To ensure that production remains uninterrupted, proper boiler maintenance is critical. Regular inspections, cleaning, and servicing are essential to keep boilers running efficiently. Preventative maintenance practices can detect potential issues before they escalate, minimizing downtime and reducing repair costs.

Moreover, compliance with safety regulations is non-negotiable in industrial settings. Boilers are subject to stringent standards, and failing to adhere to these can result in severe consequences, including accidents and legal penalties. Thus, investing in well-maintained and high-quality boiler systems, along with a robust maintenance schedule, is a wise decision for any production factory.

Conclusion

In conclusion, boilers are indispensable in the operation of production factories. They not only contribute to the efficiency and reliability of manufacturing processes but also present opportunities for advancements in sustainability. As industries continue to evolve and adapt to new technologies, the importance of energy-efficient and environmentally friendly boilers will only increase. By investing in the right boiler systems and prioritizing maintenance, production facilities can enhance their operations while being stewards of the environment. The future of manufacturing lies in integrating advanced technologies, and boilers will remain at the forefront of this transformation.

-

Industrial Electric Steam Boilers | Top Manufacturers & SuppliersNewsAug.07,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.06,2025

-

Top Electric Steam Boiler Manufacturers | AI EfficiencyNewsAug.04,2025

-

Efficient Thermal Oil Boilers with AI Optimization | Superior PerformanceNewsAug.03,2025

-

Custom Steam Boilers Manufacturer | AI-Enhanced EfficiencyNewsJul.31,2025

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025