Considerations for Purchasing a High Pressure Steam Boiler for Your Needs

Buying High Pressure Steam Boilers A Comprehensive Guide

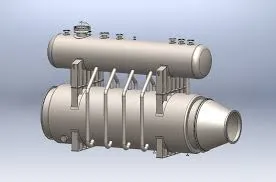

High pressure steam boilers are critical components in various industries, including power generation, manufacturing, and food processing. They are designed to produce steam at pressures exceeding 15 psi, making them essential for processes that require high temperature and pressure. When considering the purchase of a high pressure steam boiler, it is vital to understand their functionalities, types, and the factors to consider for an informed decision.

Understanding High Pressure Steam Boilers

High pressure steam boilers operate on a straightforward principle they convert water into steam using fuel or electricity. The steam generated is then used to drive turbines in power plants, heat buildings, or drive various industrial processes. The high pressure enables the steam to reach higher temperatures, which can significantly enhance the efficiency of these systems.

Boilers are classified into two main categories fire-tube boilers and water-tube boilers. Fire-tube boilers consist of a vessel filled with water and tubes carrying hot gases. They are generally simpler in design and are more suitable for smaller applications. In contrast, water-tube boilers have a more complex structure where water flows through tubes heated by external hot gases. These boilers can handle higher pressures and are often used in larger industrial settings.

Key Factors to Consider When Buying a High Pressure Steam Boiler

1. Application Requirements

The first step in purchasing a high pressure steam boiler is identifying its intended use. This includes determining the required steam pressure and temperature for your specific process. Different industries may have unique specifications regarding the quality and quantity of steam needed, so tailoring your choice to these requirements is critical.

Boiler capacity, usually measured in horsepower (HP) or pounds of steam per hour (lbs/hr), is crucial when selecting a unit. It’s essential to choose a boiler that can meet peak demands without excessive oversizing, which can lead to inefficiency and increased operational costs. Consideration of future growth in production or demand should also be factored into capacity planning.

3. Fuel Type

buy high pressure steam boiler

High pressure steam boilers can run on various fuels, including natural gas, oil, coal, or biomass. The choice of fuel will impact fuel costs, emissions, and operational efficiency. Natural gas is often favored for its cleaner burning properties, while biomass may be chosen for sustainability reasons. Ensure that the boiler design is suitable for the chosen fuel type.

4. Efficiency Ratings

Efficiency is a critical element when investing in a high pressure steam boiler. Look for units that comply with current energy efficiency standards, as higher efficiency translates to lower operating costs and reduced environmental impact. The annual fuel utilization efficiency (AFUE) ratings can help compare different models and select the most efficient option.

5. Regulatory Compliance

High pressure steam boilers must comply with local, state, and federal regulations concerning safety, emissions, and energy consumption. Ensure the manufacturer provides certified equipment that adheres to all required standards, such as ASME (American Society of Mechanical Engineers) and OSHA (Occupational Safety and Health Administration) regulations.

6. Maintenance and Support

Regular maintenance is essential for the safe and efficient operation of high pressure steam boilers. When purchasing, inquire about warranty options and the manufacturer’s support services. It's beneficial to select a supplier that offers comprehensive maintenance services and has a good reputation for customer service. This can include training for your staff on operational best practices and emergency response procedures.

7. Cost Considerations

Finally, cost should be a primary factor in your purchasing decision. Evaluate the total cost of ownership, including purchase price, installation costs, operation, maintenance, and potential repairs over its lifetime. While an initial lower price might be attractive, consider long-term savings associated with efficiency and reliability.

Conclusion

Investing in a high pressure steam boiler is a significant decision that requires careful consideration of various factors. By understanding boiler types, applications, and regulatory requirements, businesses can make informed choices that enhance productivity and ensure operational safety. Conducting thorough research and consulting with industry experts can further aid in selecting the right boiler to meet your specific needs. With the right approach, a high pressure steam boiler can provide years of reliable service and contribute significantly to your operational success.

-

Top Electric Steam Boiler Makers | AI-OptimizedNewsJul.31,2025

-

Top Electric Steam Boiler Manufacturers - High Efficiency SolutionsNewsJul.30,2025

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025