CE Certified Hot Oil Circulation Pumps for Efficient Heating Solutions and Industrial Applications

Understanding CE Certification for Hot Oil Circulation Pumps

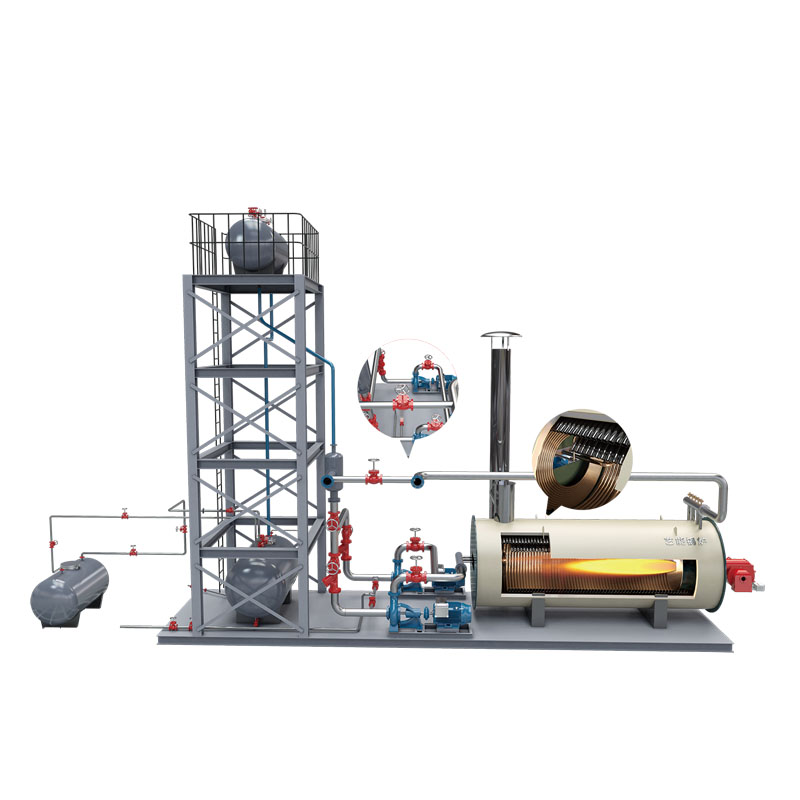

Hot oil circulation pumps play a vital role in various industrial processes, particularly in applications requiring stable and high-temperature fluid transfer. These pumps are widely used in industries such as petrochemicals, food processing, and manufacturing, where precise temperature control and reliability are essential. As global trade and manufacturing expand, the need for compliance with international safety and quality standards becomes increasingly important. One of the most recognized certifications in this domain is the CE certification.

What is CE Certification?

CE marking indicates that a product complies with European Union (EU) safety, health, and environmental protection standards. The CE stands for Conformité Européenne, meaning European Conformity. Products bearing the CE mark can be marketed within the European Economic Area (EEA), demonstrating that they meet essential requirements enforced by relevant EU directives.

For hot oil circulation pumps, the CE certification process involves rigorous testing and evaluation of design, construction, and performance. Manufacturers must provide comprehensive documentation that attests to the pump’s compliance with directives such as the Machinery Directive, Pressure Equipment Directive, and Low Voltage Directive, among others.

Importance of CE Certification

1. Market Access CE certification is often a prerequisite for selling products in the EU market. Without it, manufacturers may face restrictions or bans on their products, limiting their market potential.

2. Consumer Trust Having a CE mark on a product promotes consumer confidence. It assures customers that the hot oil circulation pump has met stringent safety and performance standards, which is particularly crucial for applications involving high temperatures and potentially hazardous materials.

3. Legal Compliance CE certification helps manufacturers comply with European regulations, thus avoiding potential legal issues. Non-compliance can lead to penalties, recalls, or even product bans, significantly disrupting business operations.

4. Competitive Edge CE certification can be a differentiating factor in a competitive marketplace. Products with CE marks are often perceived as higher quality and safer, giving manufacturers an advantage over non-certified competitors.

ce certification hot oil circulation pump

The Certification Process

The CE certification process typically involves several key steps

1. Identify Applicable Directives Determine which EU directives apply to the hot oil circulation pump. This will dictate the necessary compliance tests and documentation required.

2. Assess Conformity Conduct comprehensive assessments, including risk analysis and performance testing, to ensure the product meets the essential requirements outlined in the relevant directives.

3. Compile Technical Documentation Gather and compile technical files that include design and manufacturing details, test results, and risk assessments. This documentation is crucial for regulatory inspections.

4. Choose Notified Body (if necessary) For certain products, especially those involving higher risks, collaboration with a Notified Body—an organization designated by EU countries to assess conformity—may be required.

5. Affix the CE Mark Once the pump complies with all relevant directives, the manufacturer can affix the CE mark to the product, along with the declaration of conformity.

Conclusion

CE certification is an essential aspect of the design and manufacturing process for hot oil circulation pumps. Not only does it ensure compliance with rigorous safety and performance standards, but it also facilitates market access and enhances consumer trust. As industries continue to prioritize safety and efficiency, CE certification will remain a critical factor in the global landscape of engineering and manufacturing. For manufacturers, understanding and navigating the CE certification process is not just about compliance; it's about commitment to quality and reliability in every pump produced.

-

Electric Steam Boiler Manufacturers: Efficient Industrial SolutionsNewsAug.15,2025

-

Leading Electric Steam Boiler Manufacturers for IndustryNewsAug.14,2025

-

Buy Waste Heat Boilers: Custom, Efficient & Affordable SolutionsNewsAug.13,2025

-

Electric Steam Boiler Manufacturers | Industrial Power & EfficiencyNewsAug.12,2025

-

Electric Steam Boiler Manufacturers: Efficient & Reliable SolutionsNewsAug.11,2025

-

China Steam Boiler Price: Efficient Industrial Systems & BurnersNewsAug.10,2025