cheap steam boiler pressure

Understanding Cheap Steam Boiler Pressure An Insight into Efficiency and Safety

In industrial and commercial settings, steam boilers play a crucial role in providing heat and energy for various applications. Among the different factors that affect boiler performance, pressure is one of the most significant. This article aims to shed light on the importance of boiler pressure, especially in the context of cheap steam boilers, and how it influences efficiency, safety, and overall operational costs.

What is Boiler Pressure?

Boiler pressure refers to the amount of steam pressure that a boiler can produce. It is typically measured in pounds per square inch (PSI) or bar. Understanding and managing boiler pressure is essential, as it directly impacts the system's ability to generate steam efficiently.

The Importance of Pressure in Steam Boilers

1. Efficiency Steam boilers operate on the principle of heat exchange. The efficiency of this process is closely tied to the pressure of the steam produced. Higher pressure typically means higher temperatures, which can enhance the efficiency of heat transfer to the end-use application. However, excessively high pressure can lead to a decrease in efficiency, as the heat may not be effectively utilized. Therefore, maintaining optimal pressure is vital for achieving economical operation.

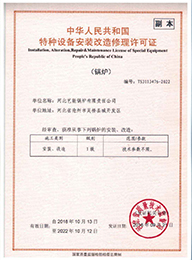

2. Safety Operating a steam boiler involves inherent risks, especially when it comes to pressure management. Cheap steam boilers, while appealing due to their cost-efficiency, may compromise on safety features that prevent excessive pressure build-up. It is crucial that these boilers are equipped with proper safety valves and gauges to monitor pressure levels. Regular maintenance and inspection are essential to ensure that safety mechanisms are functioning correctly, as neglecting this could lead to catastrophic failures, including explosions.

3. Cost Implications The operational pressure of a boiler can significantly influence running costs. Low-pressure systems often consume more fuel to achieve the desired heating effect, leading to higher operational costs. Conversely, high-pressure systems are generally more fuel-efficient but come at a higher initial investment and maintenance expense. Cheap steam boilers might save costs upfront, but their long-term efficiency should be carefully evaluated to avoid escalating costs over time.

cheap steam boiler pressure

Factors Affecting Boiler Pressure

Several factors can affect the pressure in a steam boiler, including

1. Fuel Type The type of fuel used can significantly impact the pressure levels in a boiler. Different fuels burn at different temperatures and efficiencies, which can result in varying steam pressures.

2. Water Quality The presence of impurities in the water used in the boiler can lead to scaling and corrosion, affecting the boiler's ability to maintain consistent pressure. Using treated or demineralized water can help preserve boiler integrity and performance.

3. Design and Maintenance The design of the boiler itself plays a role in how it handles pressure. Regular maintenance, including cleaning and inspection of all components, ensures that the boiler operates safely and efficiently without unnecessary pressure fluctuations.

Conclusion

When considering the use of cheap steam boilers, understanding the implications of steam pressure is crucial. While these boilers may provide significant upfront savings, factors such as efficiency, safety, and long-term operational costs cannot be overlooked. Proper pressure management through regular monitoring, maintenance, and adherence to safety protocols will ensure that a steam boiler operates safely and efficiently, ultimately leading to greater value for investment.

Ultimately, the choice of a steam boiler should balance cost with functionality and safety, making it essential to delve into comprehensive research and understanding of the specific requirements needed for pressure management in steam systems. It's not just about finding the cheapest option; it's about investing in a solution that meets both efficiency and safety standards.

-

Top Electric Steam Boiler Manufacturers – Efficient Industrial SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers | Reliable Industrial SolutionsNewsJul.29,2025

-

OEM Steam Boiler Solutions for Custom Needs | High Efficiency & VersatilityNewsJul.29,2025

-

High-Efficiency Thermal Oil Boiler for Industrial Heating SolutionsNewsJul.29,2025

-

Top Electric Steam Boiler Manufacturers for Industrial EfficiencyNewsJul.28,2025

-

Top Electric Steam Boiler Manufacturers | Industrial Solutions & CustomizationNewsJul.27,2025